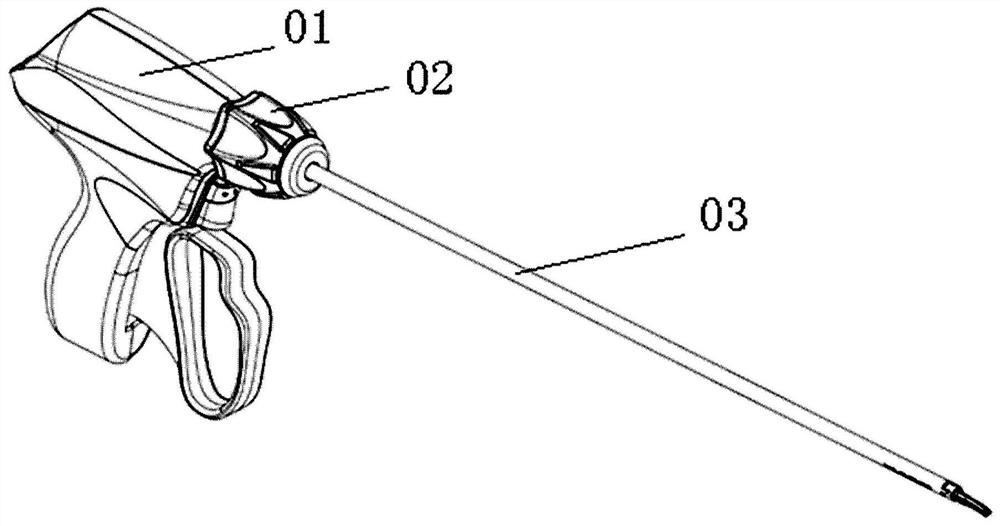

Connecting mechanism of ultrasonic scalpel and energy converter and ultrasonic scalpel assembly adopting connecting mechanism

A connection mechanism and ultrasonic scalpel technology, applied in the field of medical equipment, can solve problems such as inconvenient operation, unstable torque value, and damage to the performance of transducer cables, so as to improve the daily use time, stable and reliable torque value, and reduce Product Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

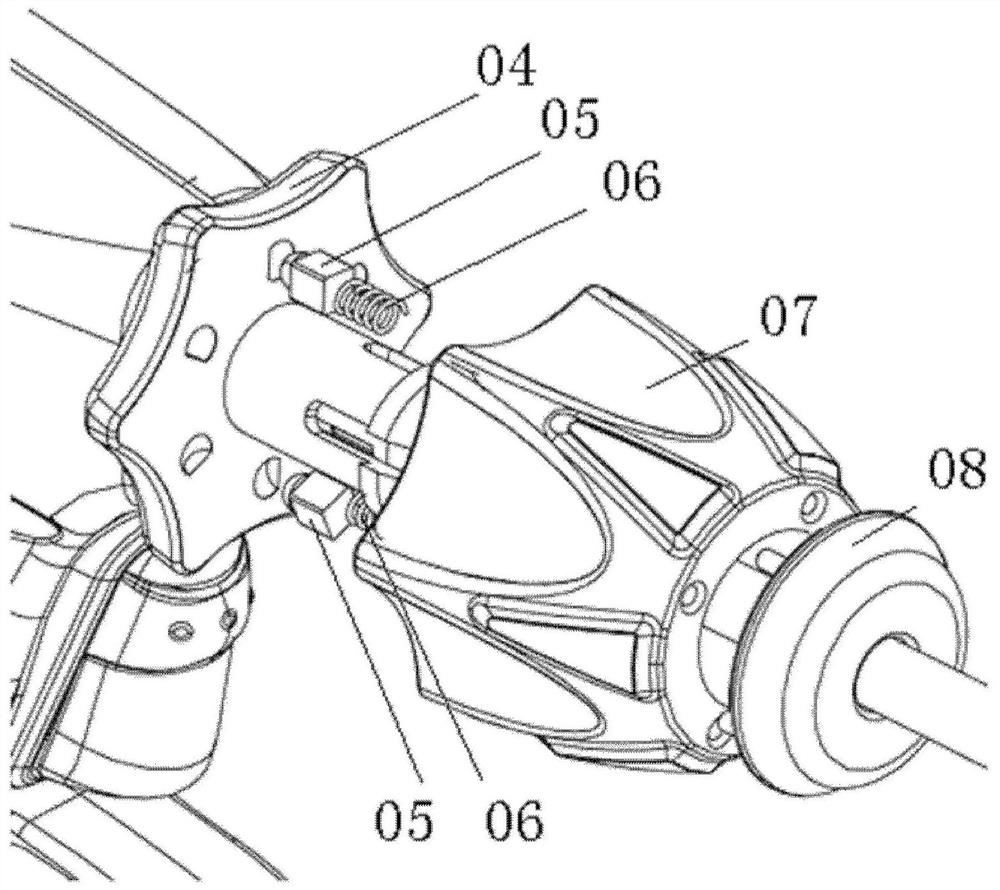

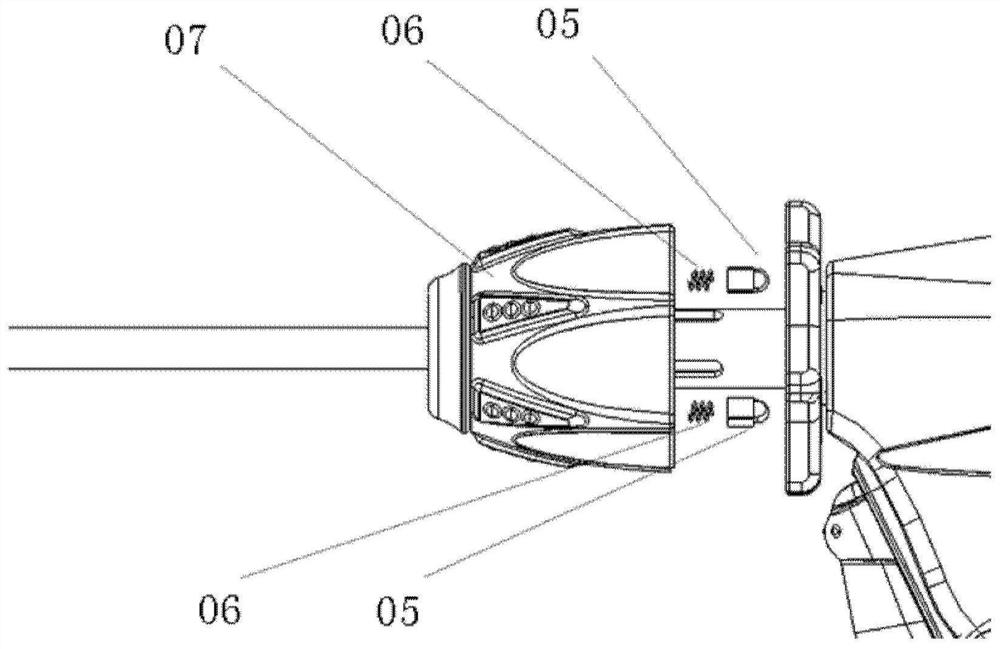

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0044] The invention discloses a connection mechanism between an ultrasonic knife and a transducer, comprising:

[0045] Tighten the turntable, which is a rotating body structure with the insertion direction of the ultrasonic knife as the axis, the axis forms a through hole to cover the ultrasonic knife, and the ultrasonic knife can rotate synchronously with the rotating cap through a pin or a snap-in structure; one end of the tightening turntable is set It has a threaded or snap-fit structure, which is used to connect with the sleeve structure containing the transducer; the other end is a limiting plane with several grooves on it, which are used to cooperate with the torque pin installed on the rotating cap , or, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com