Automatic seeder with adjustable seeding distance

An adjustable seeder technology, applied in the parts of seeder, seeding, fertilization devices, etc., can solve the problems of low efficiency, high labor intensity, difficult operation, etc., and achieve easy seed slipping, reasonable structure, and convenient sowing precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

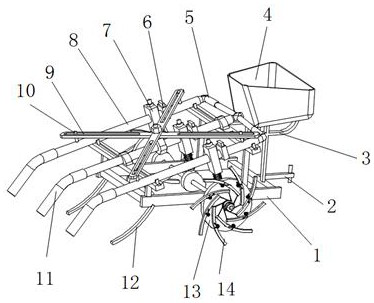

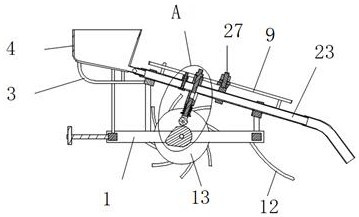

[0040] Example: Reference Figure 1-8 The shown automatic seeder with adjustable sowing distance includes a base frame 1. The base frame 1 can be made of hard materials in the prior art, such as a frame welded by steel pipes.

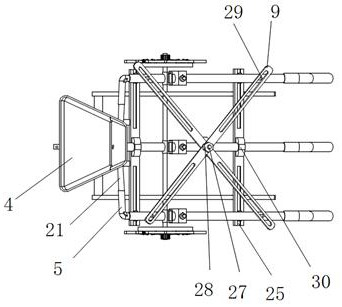

[0041] The top side of the base frame 1 is fixedly equipped with a hopper 4 through the support frame 3, and the top side of the base frame 1 is fixedly installed with two fixed cross bars 25, the two fixed cross bars 25 are parallel to each other and are located at different heights, and the top side is equipped with The main chute 26 and the top sides of the two fixed cross bars 25 are provided with three feed pipes 8 , and the feed pipes 8 located in the middle are respectively fixedly installed on the two fixed cross bars 25 through two first fixed blocks 30 , the feed pipes 8 positioned at both sides are slidably installed in the two main chutes 26 through two slide blocks 22, and the seeds enter the three feed pipes 8 respectively through the hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com