Multifunctional agricultural machinery structure

A multi-functional technology for agricultural machinery, applied in the field of agricultural machinery, can solve the problems of no split design, poor operating environment for agricultural machinery operators, etc., and achieve the effect of convenient operation and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

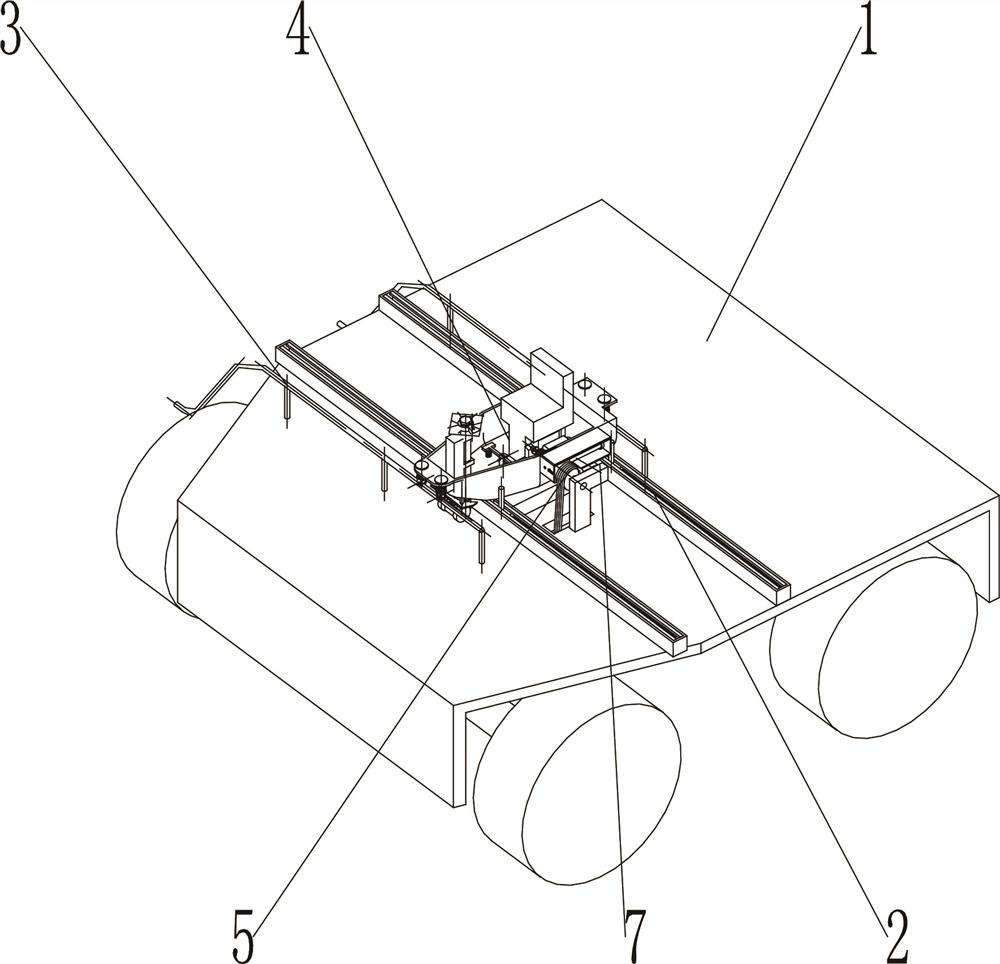

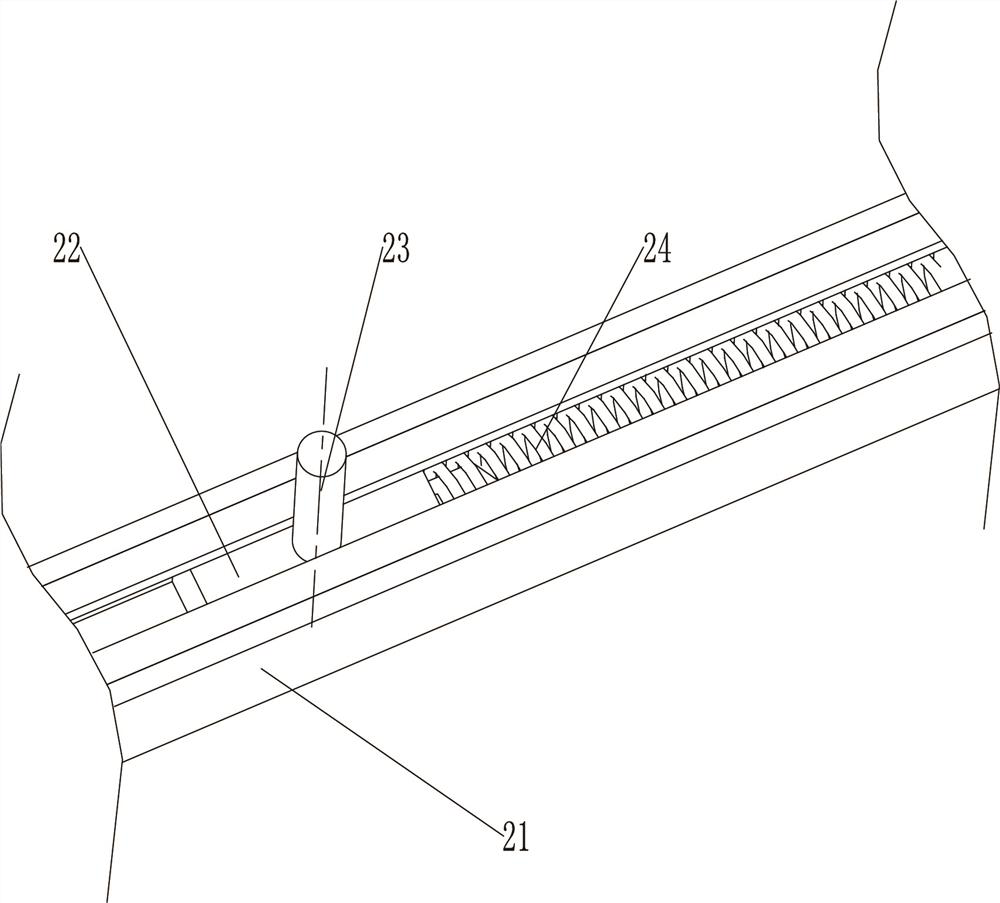

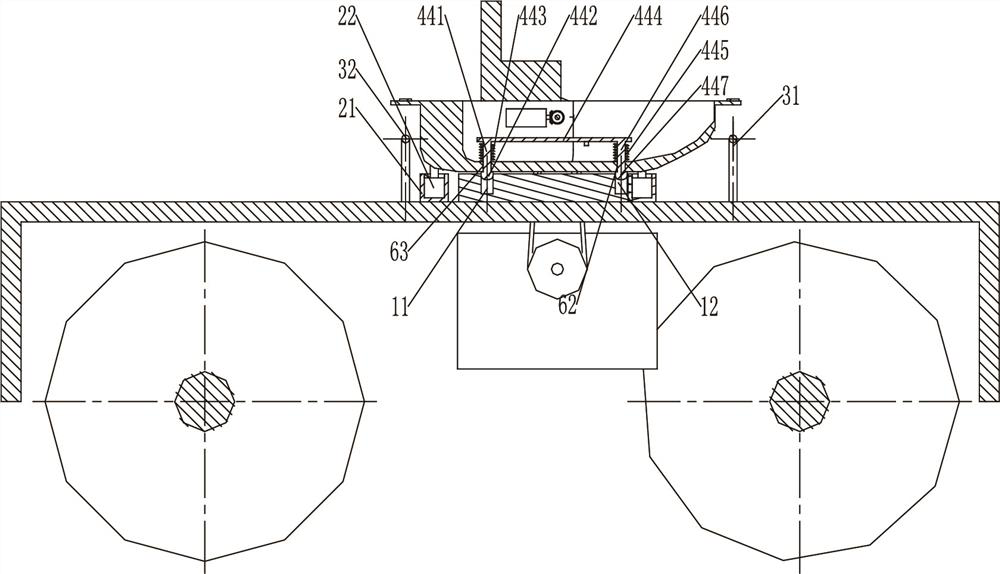

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 9 , a multifunctional agricultural machinery structure, comprising an agricultural machine main body 1, an automatic rebound device 2, a track 3, a split trolley 4, a power transmission device 5 and a rope 7, the automatic rebound device 2, a power transmission device 5, a track 3 and the rope 7 are both arranged on the main body 1 of the agricultural machine, and the split trolley 4 is slidably arranged on the track 3 and frictionally connected with the power transmission device 6 .

[0034] Wherein track 3 is provided with left and right two, described automatic rebound device 2 is also provided with left and right two, and two automatic rebound devices 2 are arranged on the inside of two tracks 3.

[0035] The split type trolley 4 comprises a trolley body 6, a pulley device 41, a winch wheel device 42, a seat 43, a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com