Backward walking type self-propelled working machine

A technology of walking backwards and working machines, which is applied to harvesters, lawn mowers, agricultural machinery and implements, etc., and can solve problems such as poor user comfort and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

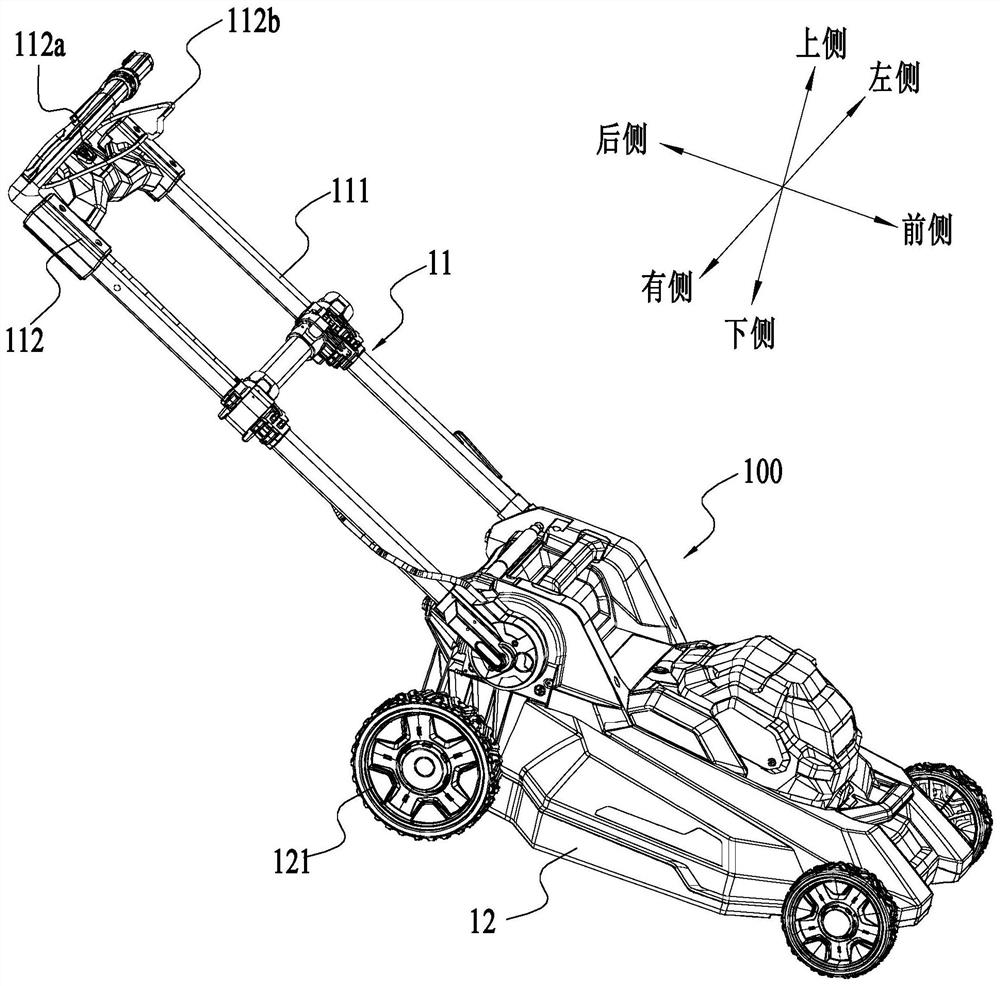

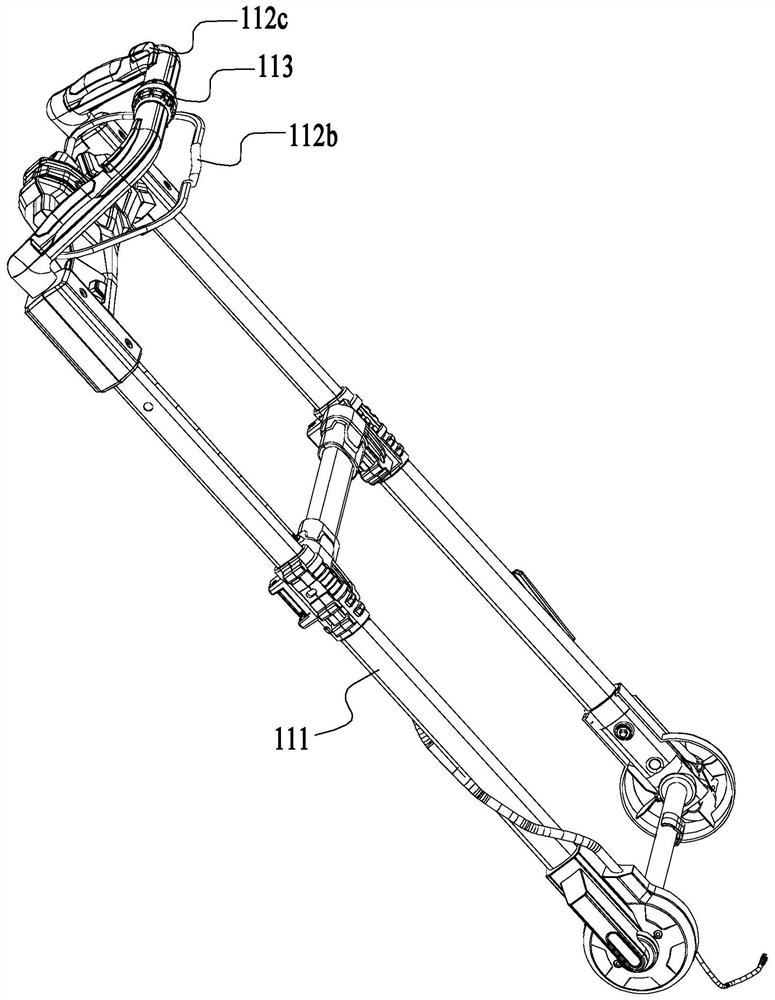

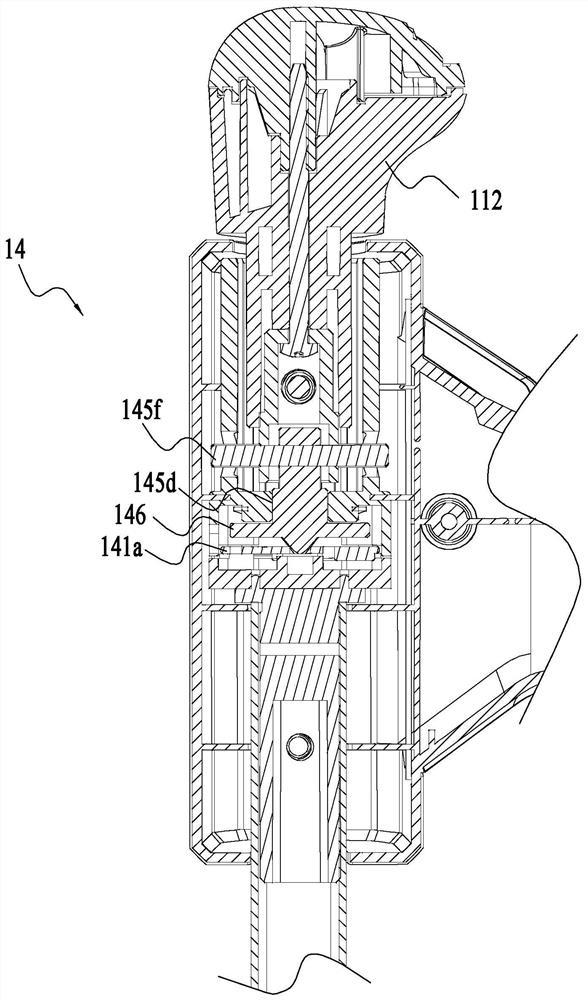

[0031] figure 1 A rear-propelled self-propelled working machine is shown, which may specifically be a lawnmower, a snowplow, or a trolley, or other working machines with self-propelled functions. As an optional implementation manner, a lawn mower is taken as an example for introduction below. Such as figure 1 As shown, the lawn mower 100 mainly includes a handle device 11 and a host 12 . Wherein, the main engine 12 includes a walking assembly 121 and a power mechanism (not shown in the figure). Specifically, the lawn mower 100 is a hand push lawn mower 100 . The handle device 11 is connected to the main unit 12 for a user to operate the lawn mower 100 at the rear side of the lawn mower 100 . It can be understood that other rear-propelled self-propelled working machines such as snowplows and trolleys may also include components such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com