Tool and method for quickly adjusting equipment before thread rolling

A technology of rapid adjustment and adjustment method, which is applied in the direction of threaded products, other household appliances, household appliances, etc., can solve the problems of unfavorable production organization, low adjustment accuracy, time-consuming and labor-intensive, etc., and achieve simplified axial relative position Effect of adjustment process, simplified adjustment process, and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] The method for adjusting the quick adjustment tooling of the equipment before thread rolling and rolling comprises the following steps:

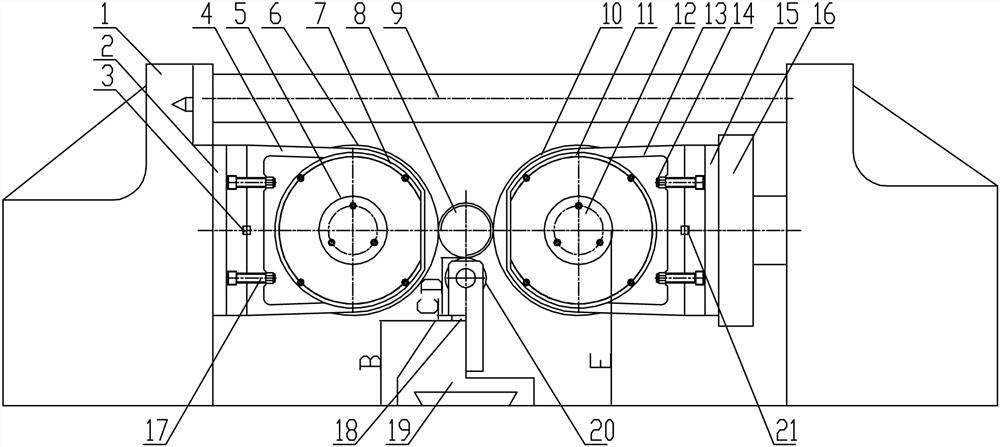

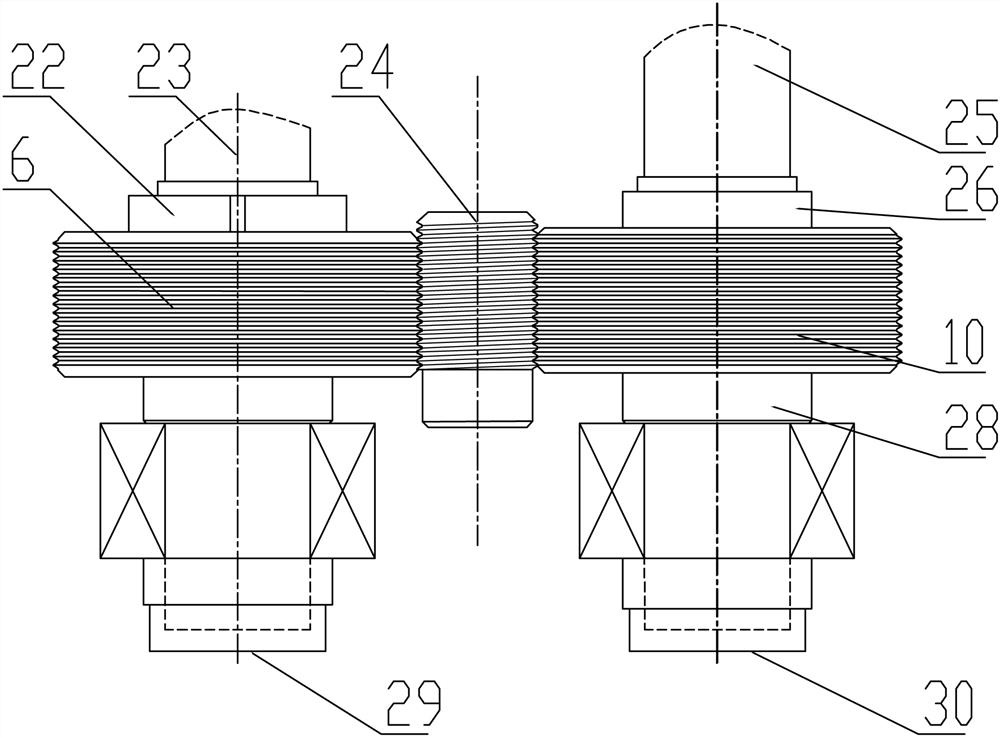

[0051] Step 1, the rotation angle adjustment of the first rotating base 2 and the second rotating base 15, that is, the adjustment of the helix angle:

[0052] According to the helix angle λ of the rolled thread, the value of the rotation angle of the first rotating base 2 is converted into the vertical distance A between the outer edge of the top of the first rotating base 2 and the top of the bed 1;

[0053] The rotation angle value of the second rotating base 15 is converted into the vertical distance A between the top outer edge of the second rotating base 15 and the top of the driving cylinder block 16;

[0054] Step 2, the height adjustment of the lower support roller 20:

[0055] The outer circle of the finished workpiece, the height B of the roller seat 19, the height D of the support roller 20 and the height F of the spindle...

Embodiment 3

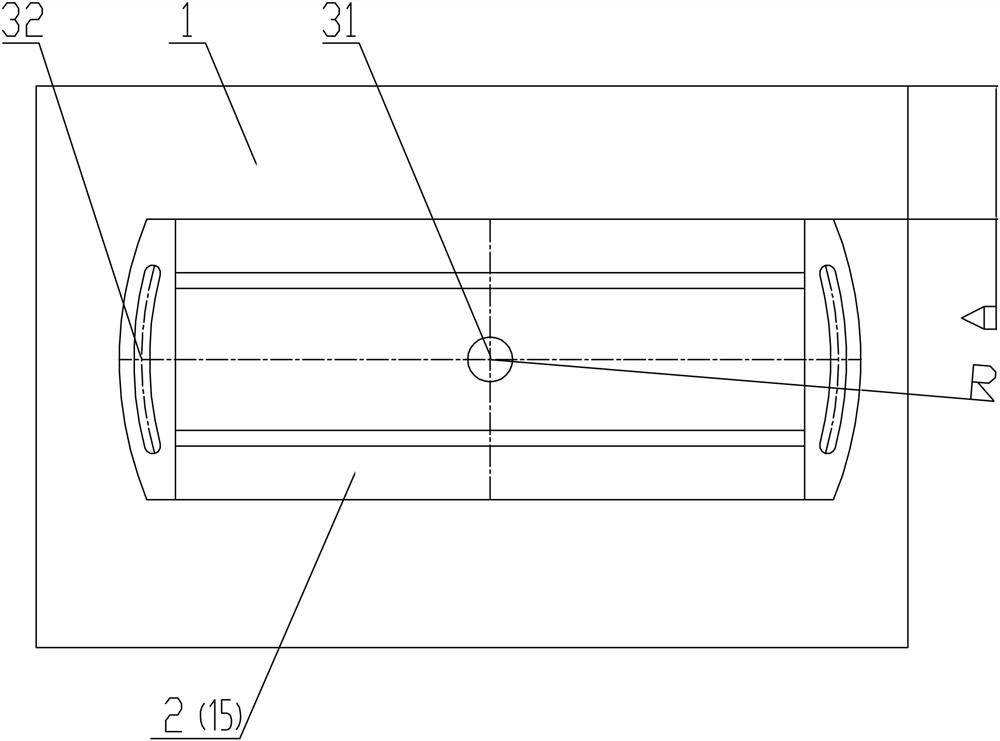

[0072] 1. Helix angle adjustment: By first measuring the distance between the bases on both sides and the bed when the angle of the main shaft of the equipment is zero degrees, and using this value as a reference to add or subtract the rotation amount of the rotating base, the inclination of the two main shafts can be accurately adjusted The angle corresponds to the helix angle of the rolled thread. For specific values, see Figure 4 . In this embodiment, the R is 330mm.

[0073] 2. Height adjustment pad thickness adjustment: by the attached figure 2 It can be obtained that the thickness of the spacer = the height of the center of the main shaft - the height of the roller seat - the height of the roller. For this reason, the thickness of the spacers for all the threaded threads is calculated, and the corresponding spacers are prepared in advance. When adjusting, select the corresponding spacers according to the size of the table That's it. For specific values, see Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com