Automatic locking vibration damper

A technology of automatic locking and anti-vibration hammer, applied in the direction of mechanical vibration damping device, etc., can solve the problems of consuming the physical strength of the staff, sliding, reducing the anti-vibration effect, etc., to improve the practicability and applicability, and the operation is fast, efficient and convenient. The effect of quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

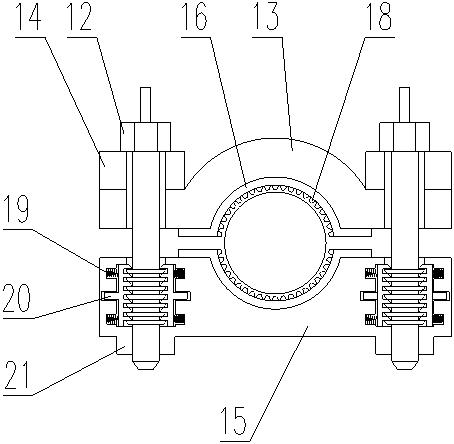

[0022] like Figure 1-6 As shown, the automatic locking anti-vibration hammer includes a main hammer head 2 and a connecting rod 4, both ends of the connecting rod 4 are slidably connected to a connecting jack block 3, and the connecting jack block 3 is rotatably connected to a main hammer Head 2, the main hammer head 2 is connected with an adjustment counterweight 11; the inside of the connecting top block 3 is provided with a cavity, the bottom of the cavity is arc-shaped, and a compression arc plate is arranged in the cavity 28, the top of the compression arc plate 28 is rotatably connected with a compression bolt 29, and the compression bolt 29 passes through the top of the connection top block 3 and is threadedly connected with the connection top block 3; the middle part of the connection rod 4 A connection sleeve 5 is connected, the top of the connection sleeve 5 is connected with an intermediate block 10, the top of the intermediate block 10 is connected with an interme...

Embodiment 2

[0025] like Figure 1-6 As shown, the automatic locking anti-vibration hammer includes a main hammer head 2 and a connecting rod 4, both ends of the connecting rod 4 are slidably connected to a connecting jack block 3, and the connecting jack block 3 is rotatably connected to a main hammer Head 2, the main hammer head 2 is connected with an adjustment counterweight 11; the inside of the connecting top block 3 is provided with a cavity, the bottom of the cavity is arc-shaped, and a compression arc plate is arranged in the cavity 28, the top of the compression arc plate 28 is rotatably connected with a compression bolt 29, and the compression bolt 29 passes through the top of the connection top block 3 and is threadedly connected with the connection top block 3; the middle part of the connection rod 4 A connection sleeve 5 is connected, the top of the connection sleeve 5 is connected with an intermediate block 10, the top of the intermediate block 10 is connected with an intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com