Railway steel rail drilling machine

A drilling machine and rail technology, applied in the field of drilling machines, can solve the problems of wasting manpower, wasting staff time, wasting rails, etc., and achieving the effects of increasing work efficiency, saving labor, and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

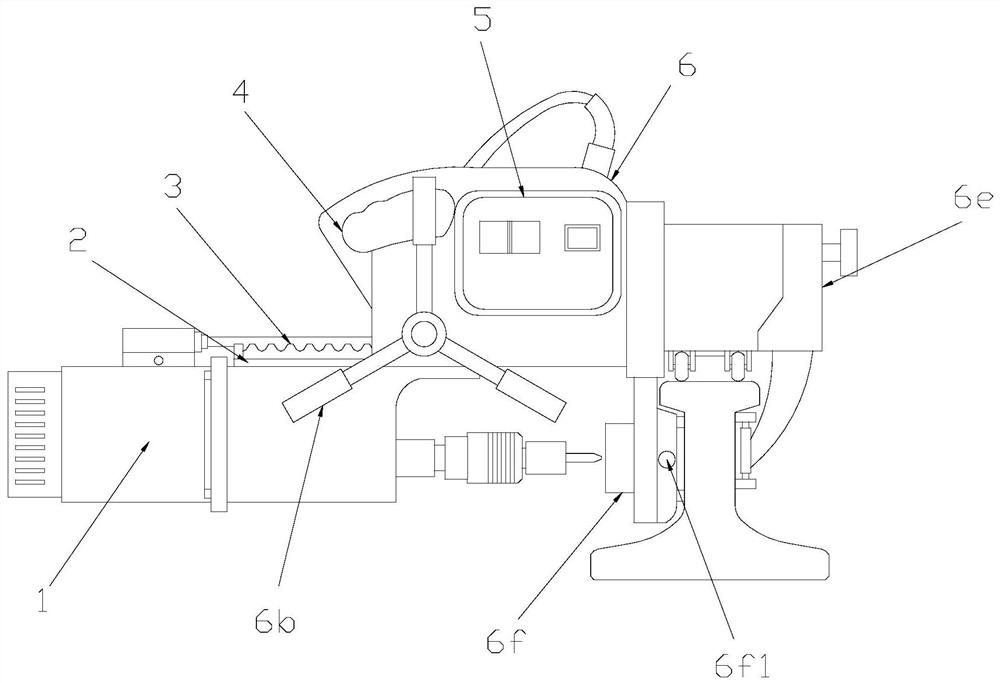

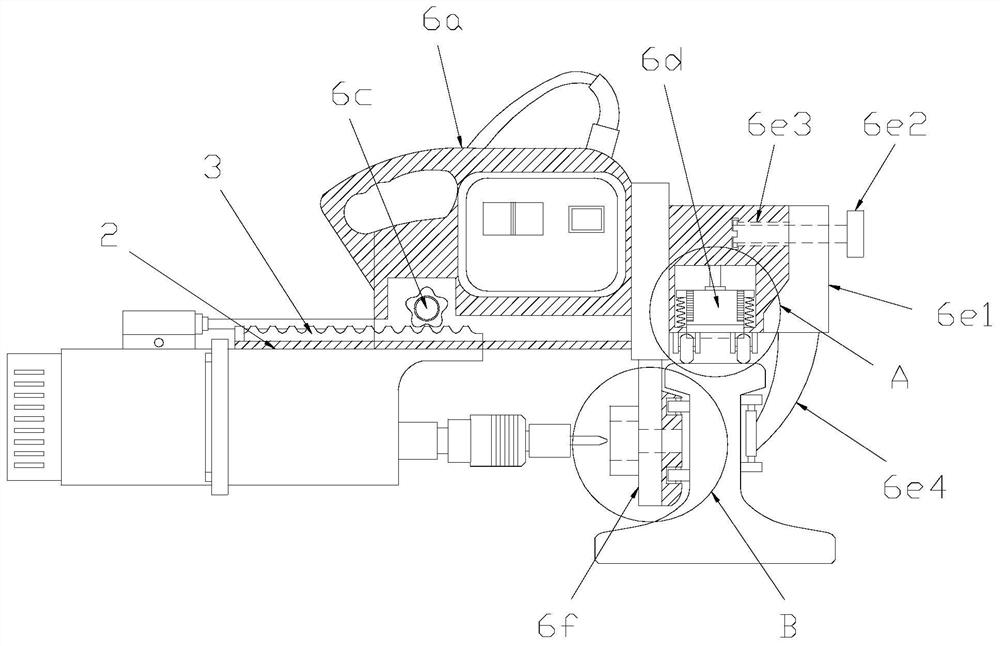

[0032] see Figure 1-Figure 6 , the present invention provides a railway rail drilling machine, the structure of which includes a drilling machine 1, a slide bar 2, a gear bar 3, a handle 4, an operation panel 5, and a mounting frame 6, and the top of the drilling machine 1 is A slide bar 2 is provided, the drilling machine 1 and the slide bar 2 are an integrated structure, the top of the slide bar 2 is provided with a gear bar 3, and the described slide bar 2 and the gear bar 3 are fixedly connected, and the The top of the drilling machine 1 is provided with a mounting frame 6, the drilling machine 1 and the mounting frame 6 are slidingly connected by a slide bar 2, and the top of the mounting frame 6 is provided with a handle 4. The installation frame 6 and the handle 4 are integrated structures, and the operation panel 5 is installed on the surface of the installation frame 6;

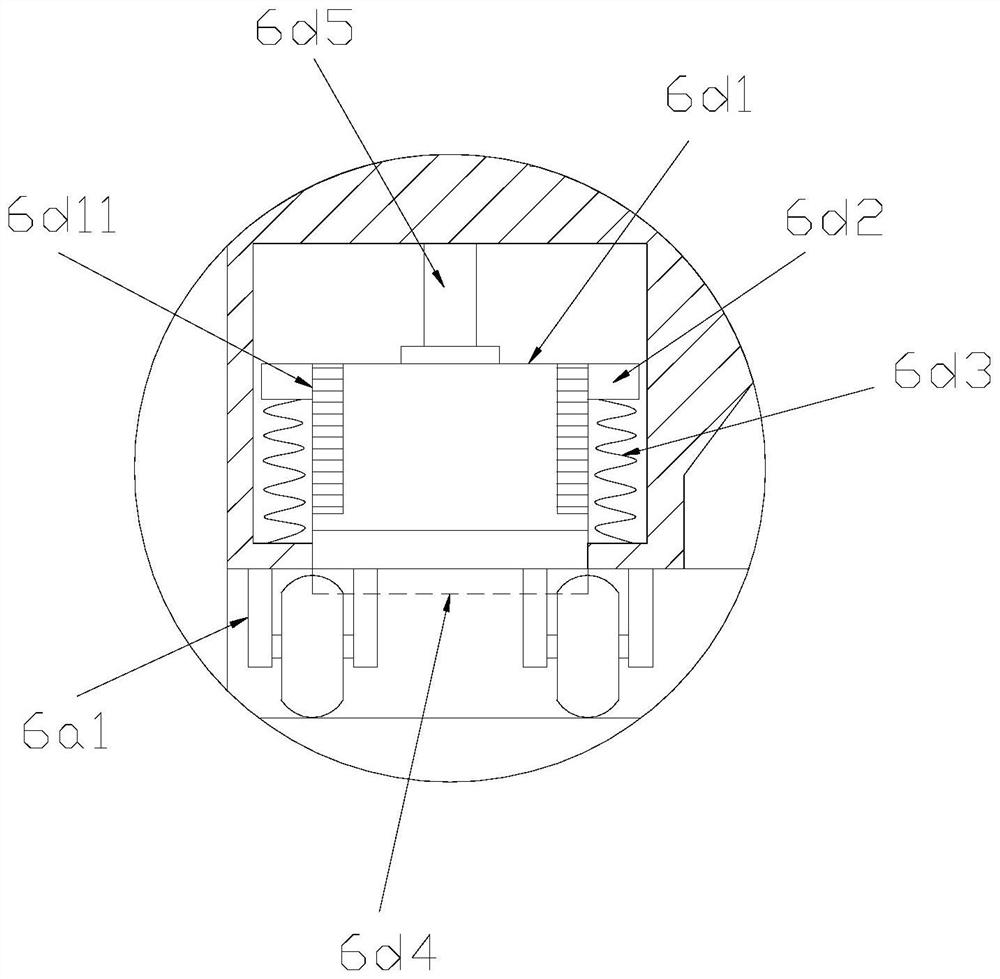

[0033]Described installation frame 6 is made up of body 6a, propulsion handwheel lever 6b, tran...

Embodiment 2

[0042] see Figure 1-Figure 6 , the present invention provides a railway rail drilling machine, the guide mechanism 6f is composed of a telescopic positioning rod 6f1, a fixed plate 6f2, a balance limit sleeve 6f3, a second perforation 6f4, and a third pulley 6f5. Telescopic positioning rods 6f1 are installed on the front and rear ends of the plate 6f2, and the left side of the fixed plate 6f2 is provided with a balance limit sleeve 6f3, and the fixed plate 6f2 is fixedly connected with the balance limit sleeve 6f3. A second perforation 6f4 is provided in the middle of the surface of the fixed plate 6f2, and four third pulleys 6f5 are equidistantly distributed on the right side surface of the fixed plate 6f2, and the fixed plate 6f2 and the third pulley 6f5 adopt a gap Cooperate.

[0043] One end of the telescopic positioning rod 6f1 is provided with a finger hole head 6f11, and the telescopic positioning rod 6f1 and the finger hole head 6f11 are welded by electric welding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com