Pressure relief system and method for integral leak rate test of AP1000 containment

A containment and leakage rate technology, which is applied in the field of overall containment leakage rate test, can solve problems such as unsuitable for renovation and expansion, long time occupied by the main line, and limited space, so as to shorten the time for refueling and overhaul, shorten the time occupied by the main line, and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

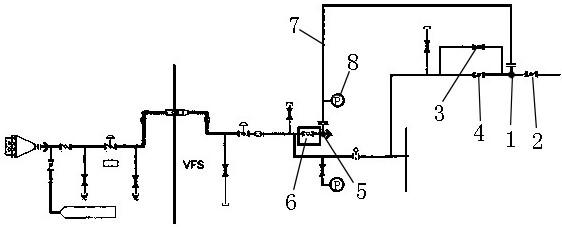

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] like figure 1 As shown, a pressure relief system for AP1000 containment overall leakage rate test, including pressure relief valve 1 3, pressure relief valve 2 4, isolation valve 6, three-way one 1, butterfly valve 2, three-way two 5, VFS exhaust air Filter unit, temporary pressure relief hose 7 and local pressure gauge 8.

[0034] Pressure relief valve 1 3 is used to realize the adjustment function of pressure relief for the overall containment leakage rate test, pressure relief valve 2 4 is used to assist pressure relief valve 1 3 to realize the adjustment function of pressure relief for the overall containment leakage rate test, isolation valve 6 is always in a closed state, which is used to isolate the air flow on the upstream and downstream sides of the isolation valve 6 . Tee one 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com