Automatic step ladder

A technology of automatic step ladders and linkage plates, which is applied in escalators, transportation and packaging, etc. It can solve the problems of unsafe hidden dangers, the elderly are struggling to go up and down stairs, and they are easy to fall, so as to achieve convenient operation, solve the difficulty, and prevent accidental falls Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

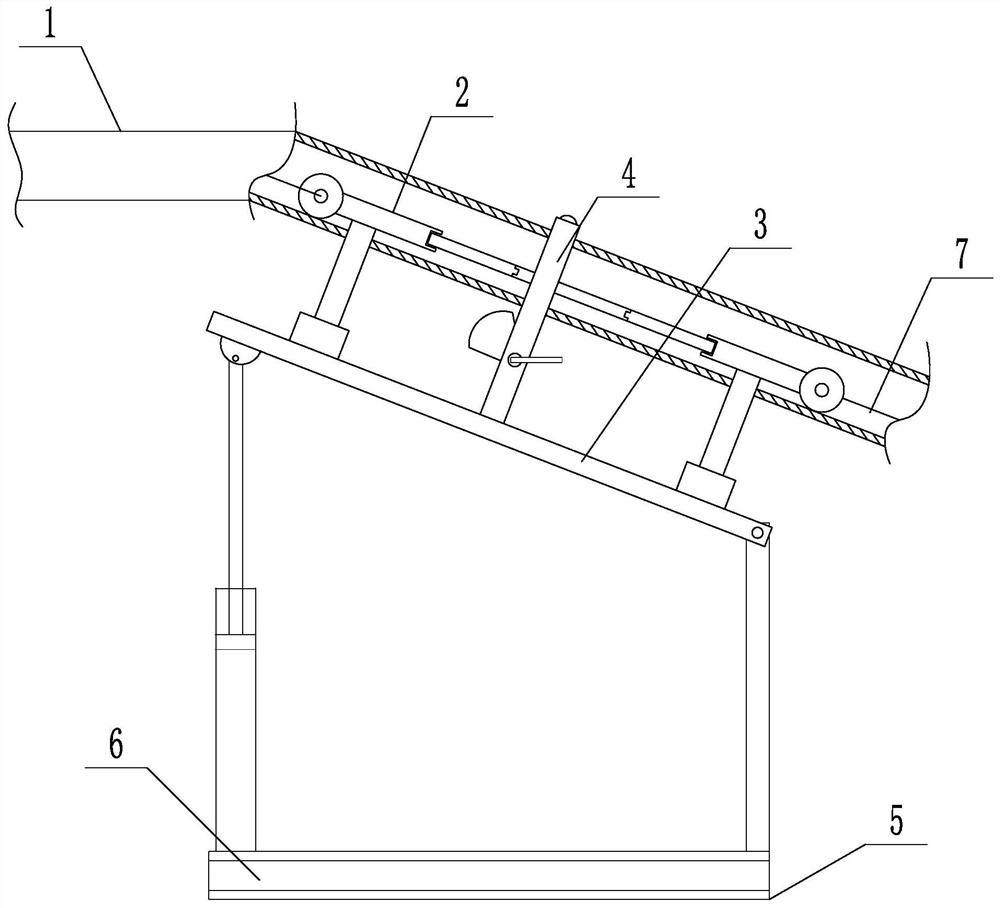

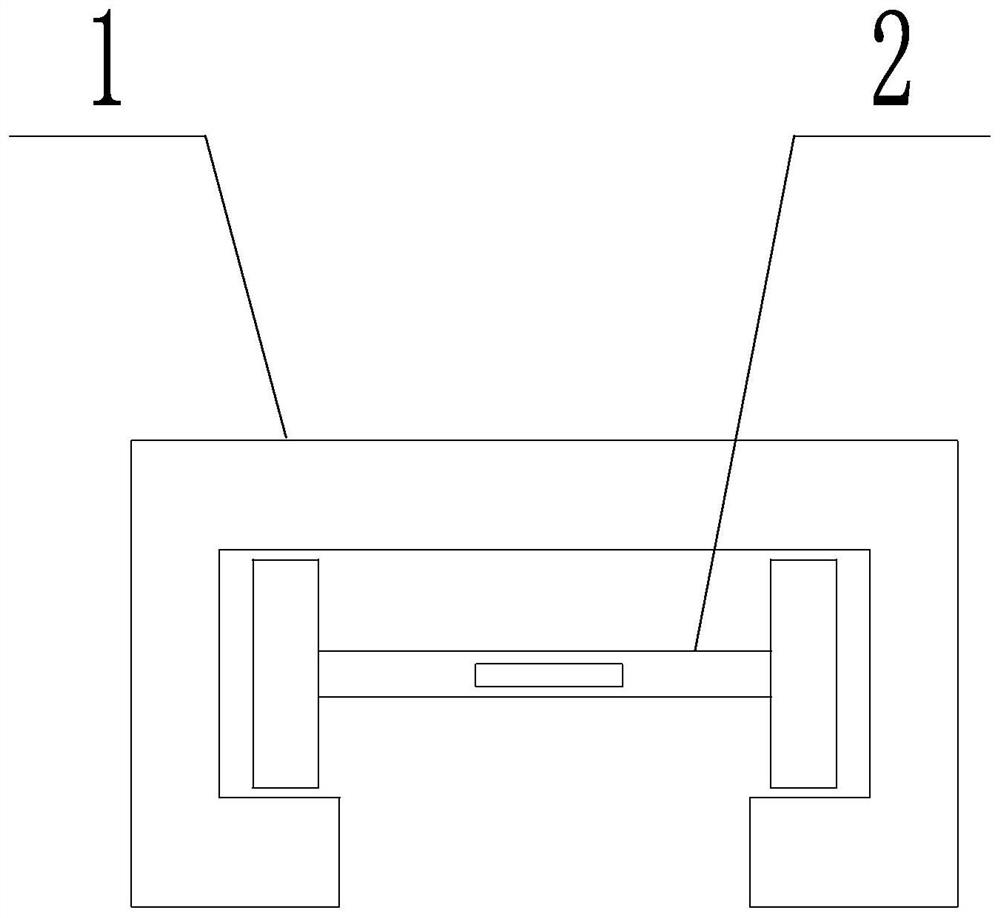

[0020] Specific implementation mode one: as Figure 1 to Figure 9 As shown, this embodiment discloses an automatic step ladder, including a channel steel 1, a rail car 2, a support device 3, a bottom plate 5, a pedal 6, a steel wire 7, a pulley 8 and a hoist 9, and the two sides of the channel steel 1 The wall is relatively bent, and the channel steel 1 is fixedly connected to the ascending stairs, the descending stairs and the wall on one side of the platform on each floor. The rail car 2 is fixedly connected, the lower end of the support device 3 is fixedly connected to the base plate 5, the base plate 5 is connected to the pedal 6 in rotation, and the channel steel 1 is internally rotatably connected to the wheel shaft of the pulley 8 pulley 8 and the channel steel 1 through the bearing Rotation connection, the channel steel 1 is provided with a steel wire 7 inside, the steel wire 7 bypasses the pulley 8, the steel wire 7 is wound on the winch 9, the two ends of the steel w...

specific Embodiment approach 2

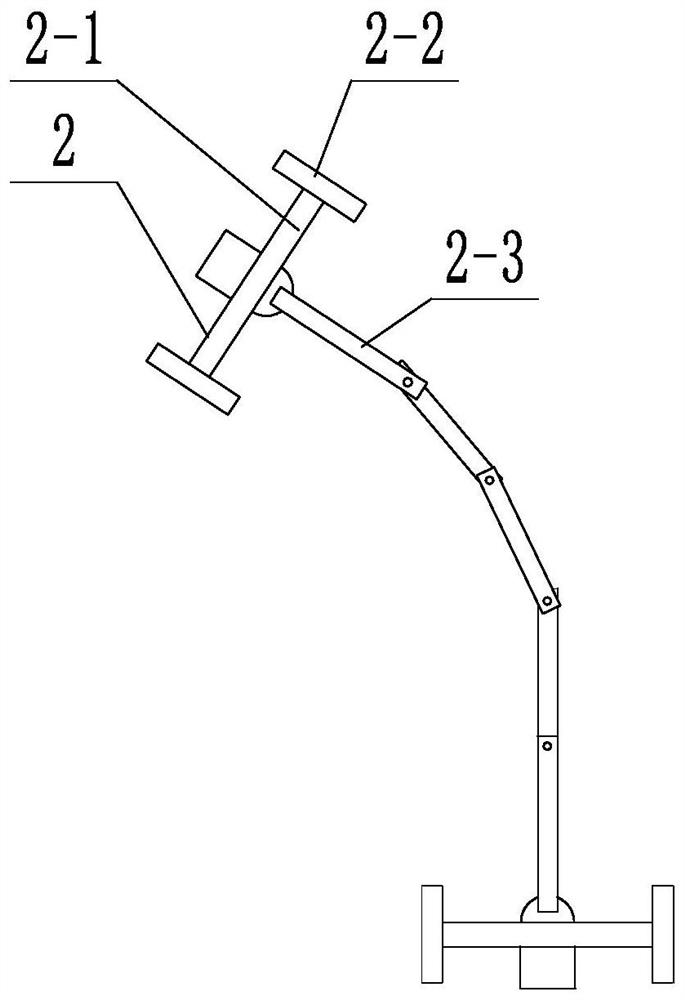

[0021] Specific implementation mode two: as image 3 As shown, this embodiment is a further description of the specific embodiment one. The rail car 2 includes: two axles 2-1, four wheels 2-2 and a plurality of hinge plates 2-3, each of which The two ends of the axle 2-1 are respectively rotatably connected with a wheel 2-2, the plurality of hinged plates 2-3 are arranged sequentially, and each adjacent two hinged plates 2-3 are hinged, and the hinged plates at both ends The plates 2-3 are respectively fixedly connected to the corresponding axles 2-1; the two ends of the steel wire 7 are respectively fixedly connected to the two axles 2-1.

specific Embodiment approach 3

[0022] Specific implementation mode three: as Figure 4 As shown, this embodiment is a further description of specific embodiment 1. The support device 3 includes a linkage plate 3-1, a sleeve 3-4, a sliding column 3-5, a limit column 3-6, two A ball shaft 3-2 and two support columns 3-3, the bottom of the hinge plate 2-3 at both ends is fixedly connected with one end of a support column 3-3 respectively, and the other end of each support column 3-3 is connected to the corresponding One ball shaft 3-2 is fixedly connected, the lower ends of the two ball shafts 3-2 are rotationally connected with the linkage plate 3-1, and the bottom of one end of the linkage plate 3-1 is hinged with a sliding column 3-5, and the sliding column The lower end of 3-5 is slidingly arranged in the sleeve 3-4, and the other end of the linkage plate 3-1 is hinged to the limit column 3-6; the sleeve 3-4 is fixedly connected to the lower end of the limit column 3-6. Bottom plate 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com