Rail fixing system

A technology for fixing systems and rails, applied in the directions of rails, fixed rails, railway fixtures, etc., which can solve the problems of component tolerances, difficult lateral force distribution to multiple installed fixed elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred exemplary embodiments are described below with reference to the drawings. In this case, identical, similar or identically acting elements are provided with the same reference symbols in the figures, and a repeated description of these elements is partially omitted in order to avoid redundancy.

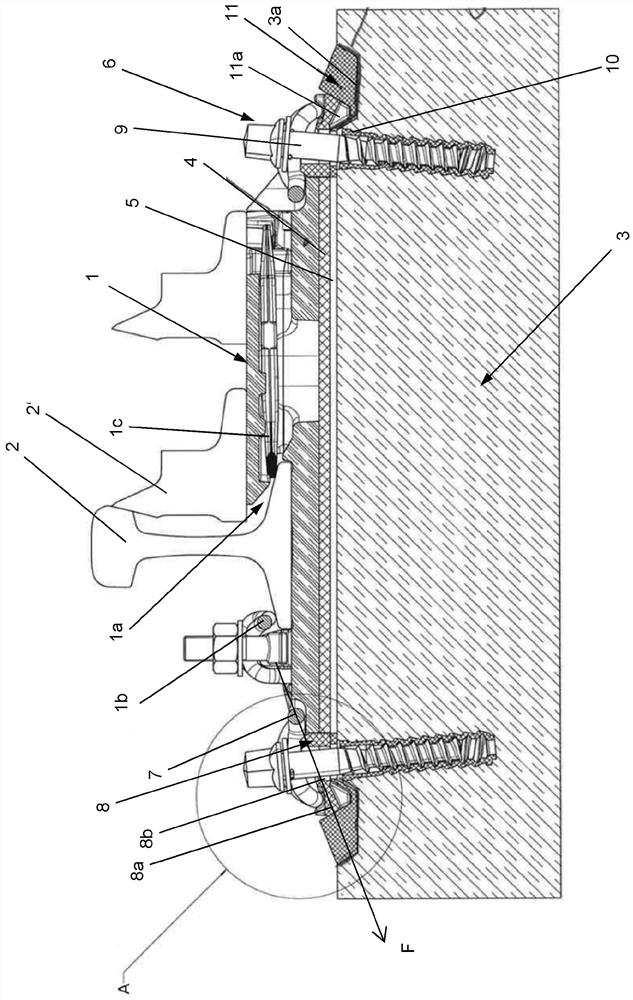

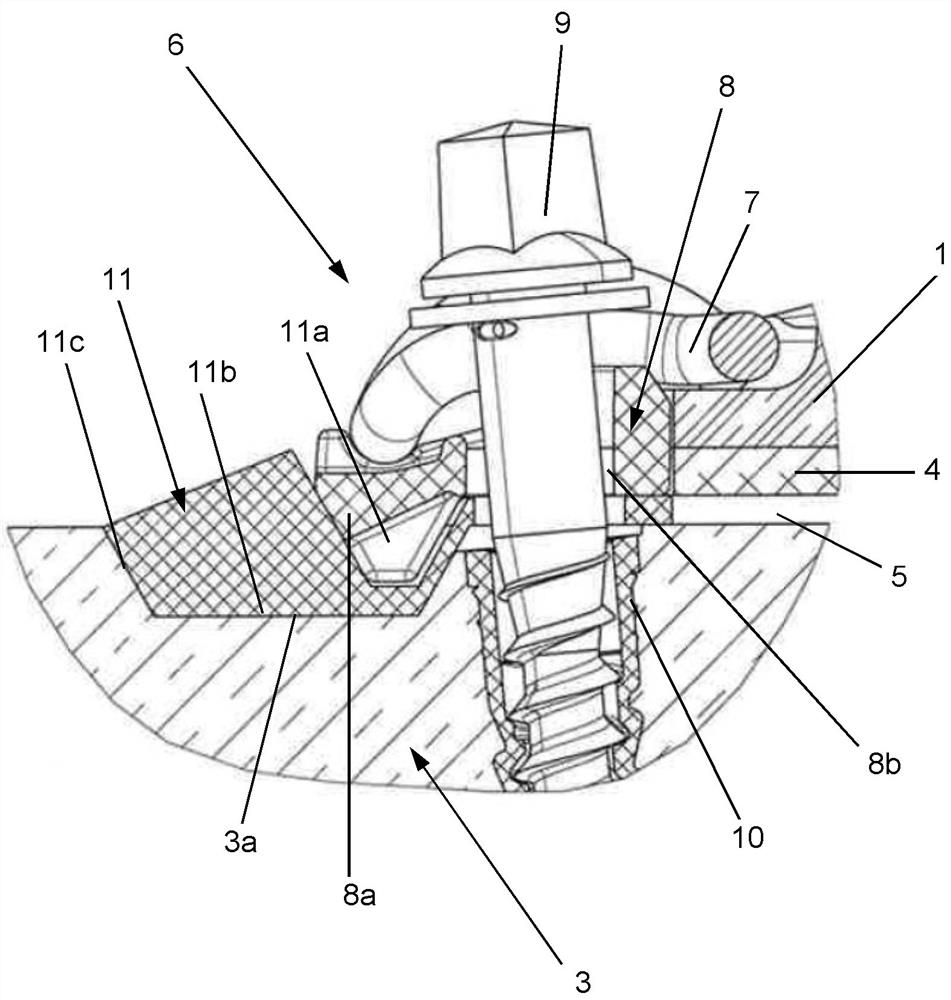

[0035] track fixing system (in figure 1 with 2 ) has a track pad 1 (also referred to as a "slider bed") for holding a rail 2 resting on the track pad. The rail backing plate 1 is, for example, a shaped part made of steel and is used together with other components of the rail fastening system to securely anchor the rail 2 to a foundation 3 , which is preferably a fixed foundation made of concrete.

[0036] In the present embodiment, the track 2 is located in the region of the switch. For this reason, in figure 1 In , an additional track section 2' is shown at two positions. The track section 2' rests on the corresponding section of the track backing plate 1 and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com