PCB board gluing device

A gluing device and a technology for PCB boards, which are applied in the direction of surface coating liquid devices, spraying devices, coatings, etc., can solve problems affecting the gluing efficiency of PCB board gluing devices, so as to improve the gluing efficiency and facilitate Effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

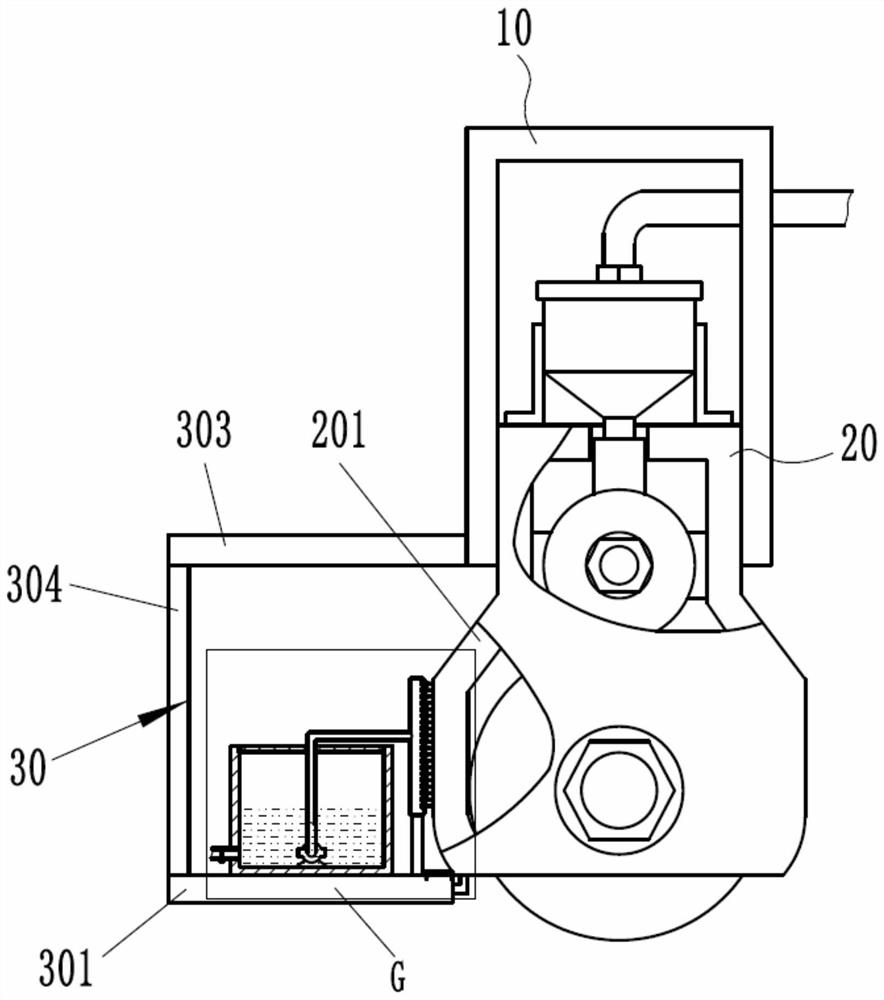

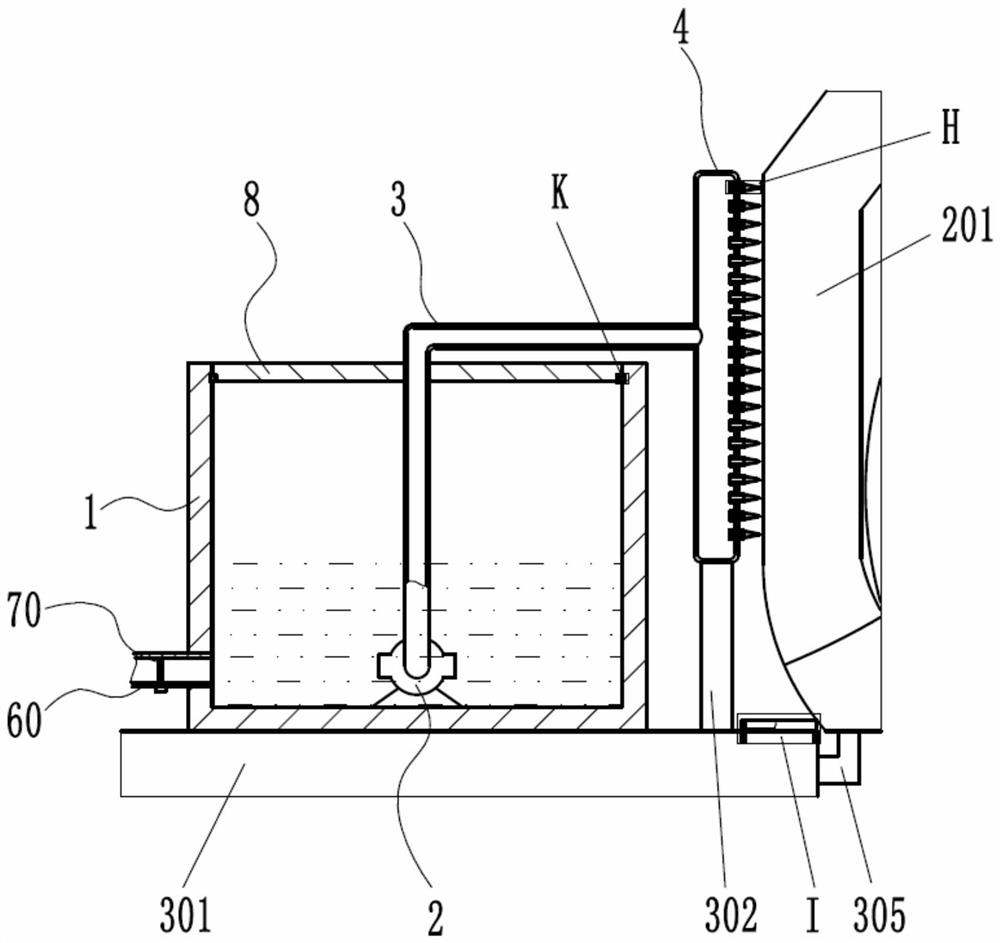

[0042] Such as figure 1 As shown, a PCB board gluing device includes a gluing mechanism, the gluing mechanism includes a bracket 10 and a housing 20, and the lower part of the housing 20 is provided with a scraping part 201, which also includes a scraping part Cleaning mechanism, the scraping part cleaning mechanism is arranged on the mounting frame 30 on the left side of the bracket 10, the scraping part cleaning mechanism can clean the glue attached to the scraping part 201, so In the process of using the PCB gluing device in the future, it can be ensured that the scraping part 201 can effectively smooth the glue attached to the surface of the gluing cylinder, thereby improving the gluing efficiency of the PCB gluing device.

[0043] In this implementation, the mounting frame 30 includes an upper plate 303, the upper plate 303 is arranged on the left side of the bracket 10, the lower end of the upper plate 303 is connected with a bottom plate 301 through a column 304, and th...

Embodiment 2

[0053] Such as Figure 6 As shown, on the basis of the first embodiment, the clamping assembly 9 also includes several pairs of rubber clamping arms 92, each pair of rubber clamping arms 92 is located on both sides of the connecting rod 711, and the rubber clamping The connecting arm 92 includes a connecting arm 921 and a rubber head 922 connected to the cantilever end of the connecting arm 921, the connecting arm 921 is connected to the corresponding side wall of the vertical cavity 611, and the rubber head 922 can be connected to the connecting rod 711 The arc-shaped groove 7111 on the corresponding side wall is engaged and connected, so as to reliably connect the waste liquid tank 6 to the bottom plate 301 .

Embodiment 3

[0055] Such as Figure 5 As shown, on the basis of the second embodiment, the lower wall of the vertical slot 3011 is provided with a magnet 50, and the magnet 50 can attract the lower end of the drive plate 71 to the lower wall of the vertical slot 3011. , Thus, when the waste liquid tank 6 is not installed on the bottom plate 301, the driving plate 71 can be prevented from moving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com