Wiping equipment for green building glass curtain wall

A glass curtain wall and green building technology, applied in construction, cleaning equipment, building maintenance, etc., can solve the problems of high cost, high labor intensity, and low cleaning efficiency, so as to reduce costs and leakage risks, reduce human operations, and reduce labor force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

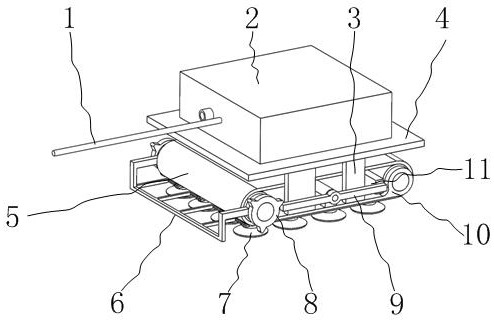

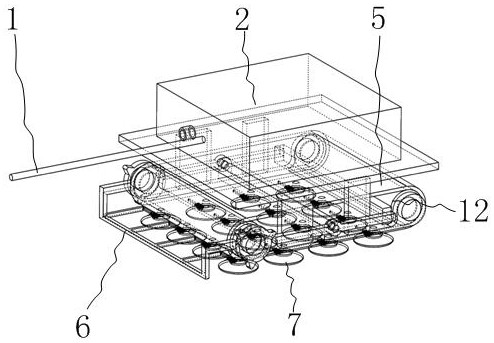

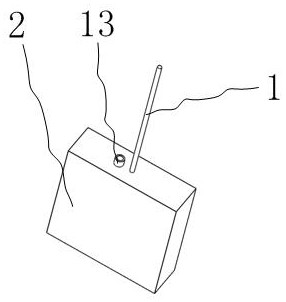

[0045] Such as figure 1 , 2 As shown, it includes a safety rope 1, a wiping mechanism 2, a support plate 3, an installation platform 4, a belt 5, a trigger frame 6, a suction cup mechanism 7, a hammer block 11, a bottom plate 10, a roller 12, a driving shaft 17, and a driving swing rod 9 , fixed support 18, driving wheel 8, wherein as Figure 5 As shown, there is a fixed ring 14 on the four corners of the base plate 10 respectively, and the effect of the fixed ring 14 is to facilitate the installation of the rollers 12; the installation platform 4 is installed on the base plate 10 through two symmetrically distributed support plates 3, and the installation platform 4 The function is to facilitate the installation of the wiping mechanism 2; Figure 9 , 10 As shown, both ends of the roller 12 have a drive shaft 21, such as Figure 9 As shown, the two rollers 12 are installed on the bottom plate 10 through the cooperation of the two drive shafts 21 installed thereon and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com