Blade-wrap-angle-adjustable impeller for centrifugal pump and centrifugal pump

A technology of vane wrap angle and centrifugal pump, which is applied to parts, pumps, pump components, etc. of the pumping device used for elastic fluid, to achieve the effect of increasing the scope of application and optimizing the installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

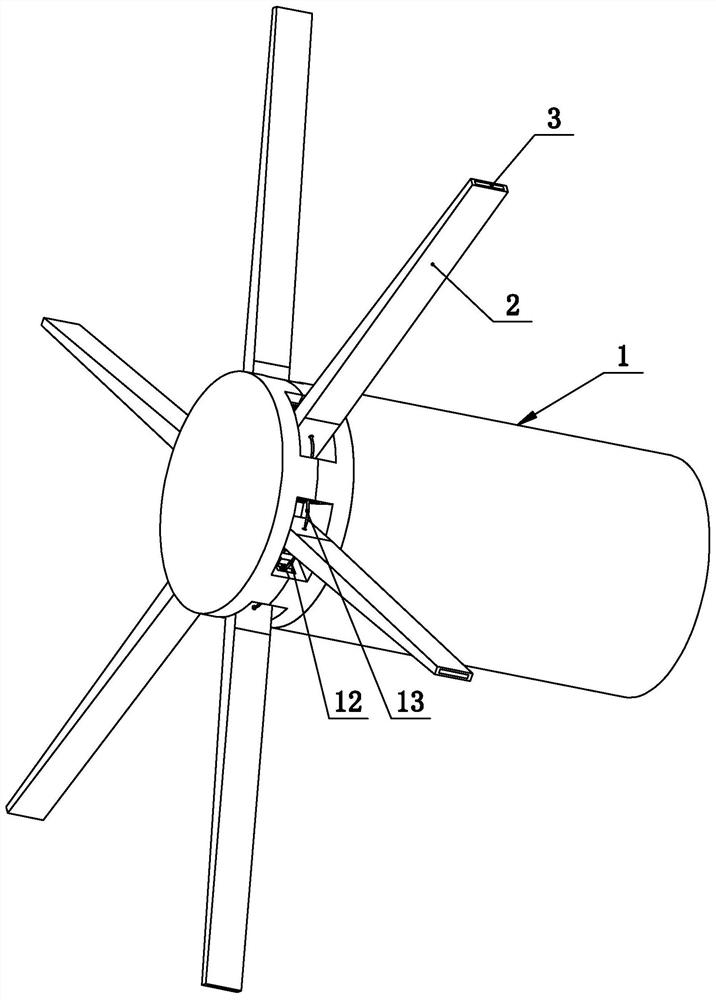

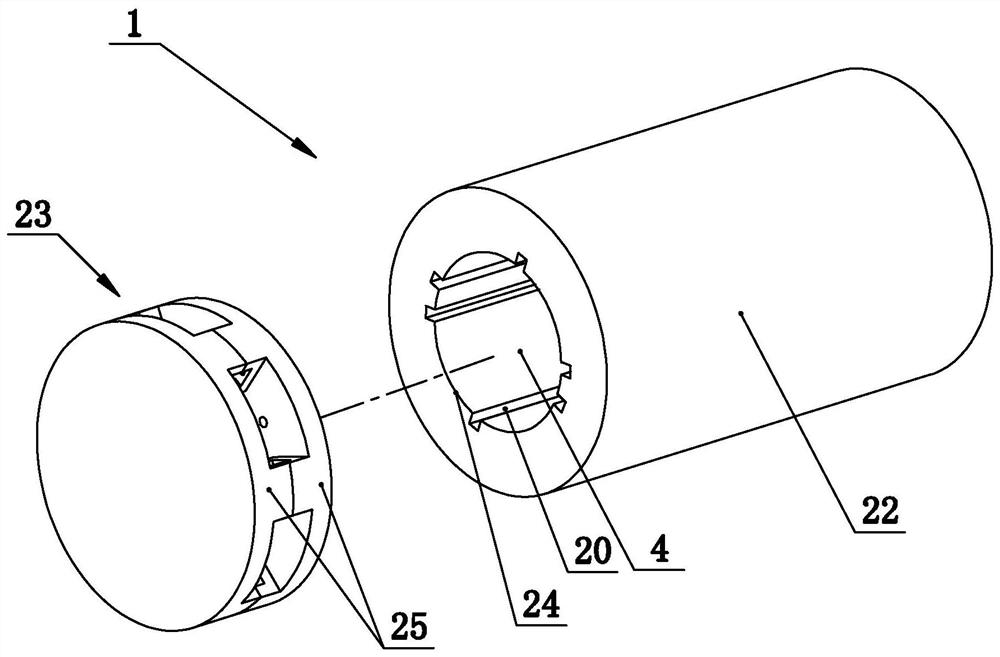

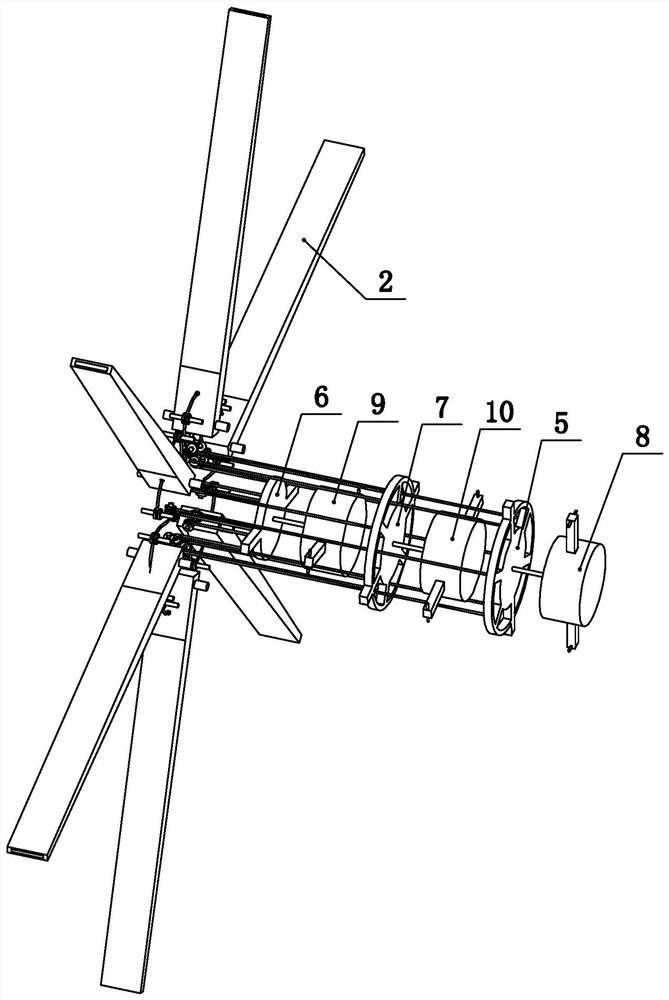

[0038] Embodiment one: if Figure 1-8Shown is an impeller for a centrifugal pump with adjustable blade wrapping angle, which includes a central shaft 1 and several blades 2, the several blades 2 are evenly distributed around the circumference of the central shaft 1, and the radial inner diameter of each blade 2 is The ends are hinged with the central shaft 1, and the radially outer end of each blade 2 is equipped with a diameter-adjusting blade 3. The central shaft 1 is provided with an inner cavity 4, and the inner cavity 4 is axially A left angle adjustment slider 5, a right angle adjustment slider 6 and a diameter adjustment slider 7 are slidably arranged, and the left angle adjustment slider 5 is connected with a left power that drives it to slide axially in the inner cavity 4 source 8, the right angle-adjusting slider 6 is connected with a right power source 9 that drives it to slide axially in the inner cavity 4, and the diameter-adjusting slider 7 is connected with a dr...

Embodiment 2

[0052] Embodiment 2: This embodiment protects a centrifugal pump, which includes a pump casing and an impeller installed in the pump casing, wherein the impeller disclosed in Embodiment 1 is used for the impeller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com