Special material visual inspection system

A visual inspection and special material technology, applied in the field of special material visual inspection system, can solve problems such as unfavorable product quality, low practicability, and large influence of subjective factors, so as to improve practicability and accuracy, flexibility and adaptability performance, improved security and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

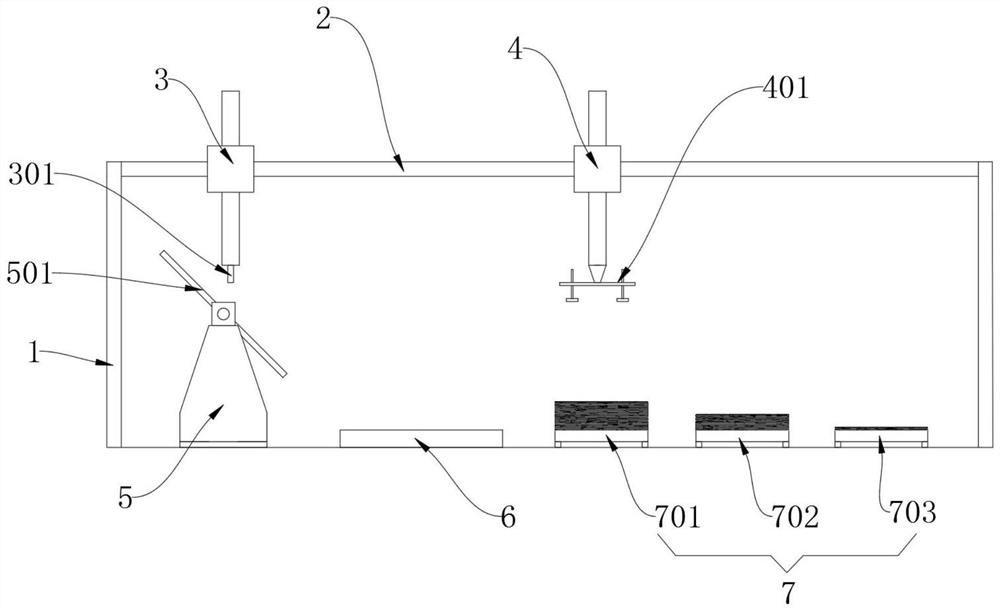

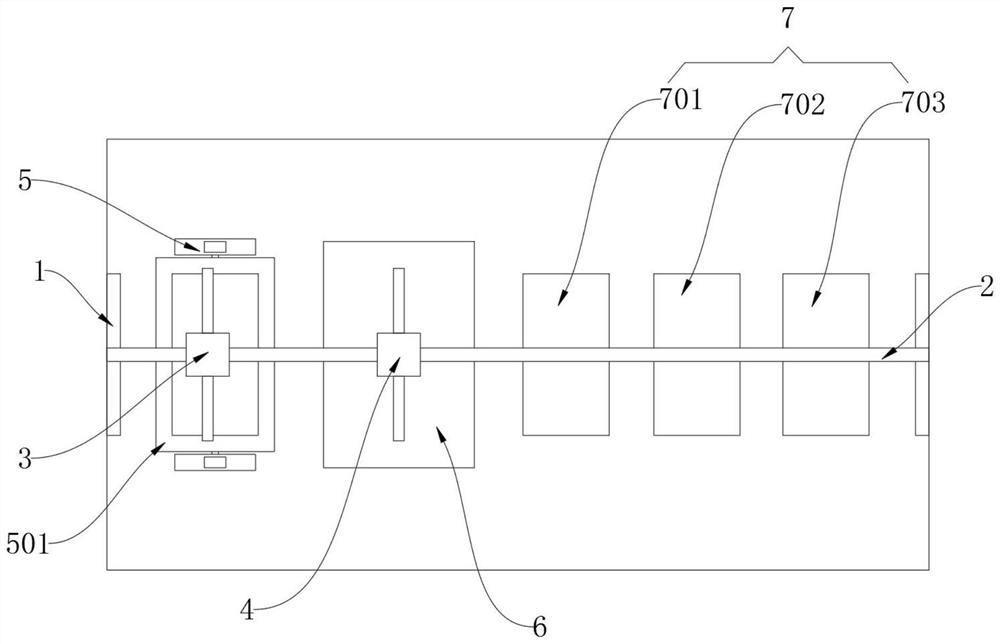

[0025] as attached figure 1 to attach figure 2 Shown:

[0026] The present invention provides a special material visual inspection system, which includes a bracket 1, a fixed rail 2, a three-axis manipulator 3, a two-axis manipulator 4, a turning table 5, a detection support table 6 and a sorting table 7; the bracket 1 is fixedly connected to the detection area The inside of the ground on both sides; the fixed track 2 is fixedly connected to the top of the support 1; the three-axis manipulator 3 and the two-axis manipulator 4 are movably connected to the outside of the fixed track 2, and the three-axis manipulator 3 and the two-axis manipulator 4 are connected to the external power supply and control The device is electrically connected, and its specific structure and working principle are existing mature technologies, which will not be repeated here; both the three-axis manipulator 3 and the two-axis manipulator 4 are equipped with anti-collision sensors, as shown in the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com