Double-motor type double-shaft vibrating screen

A shaft vibration, double motor technology, applied in the field of machinery and vibrating screen, can solve the problems of unsatisfactory vibration effect, can not well meet the screening of large-quality ore, etc., to protect equipment safety and production safety, reduce energy damage, Improve the effect of filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

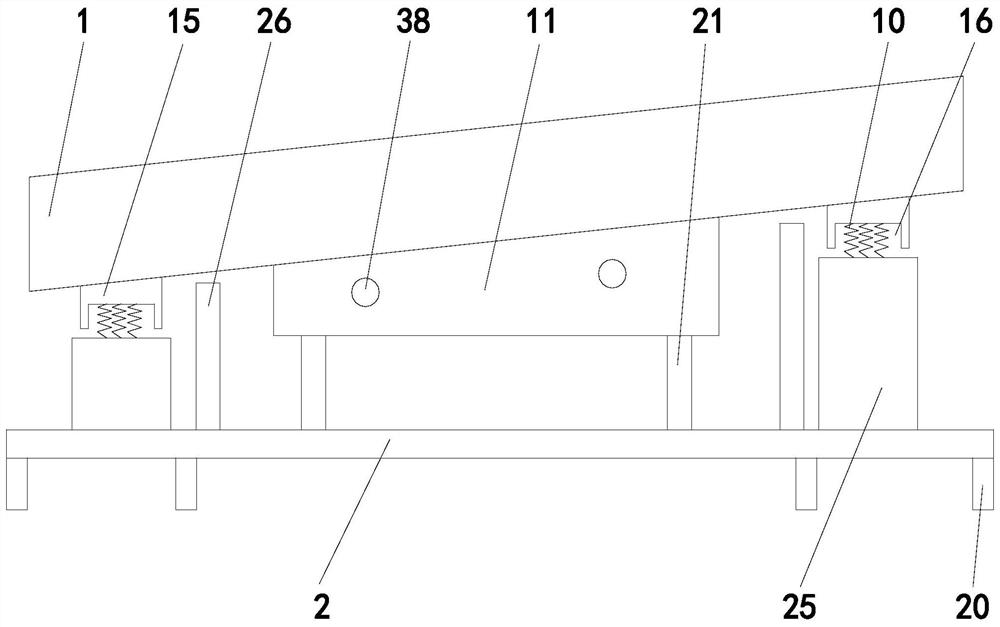

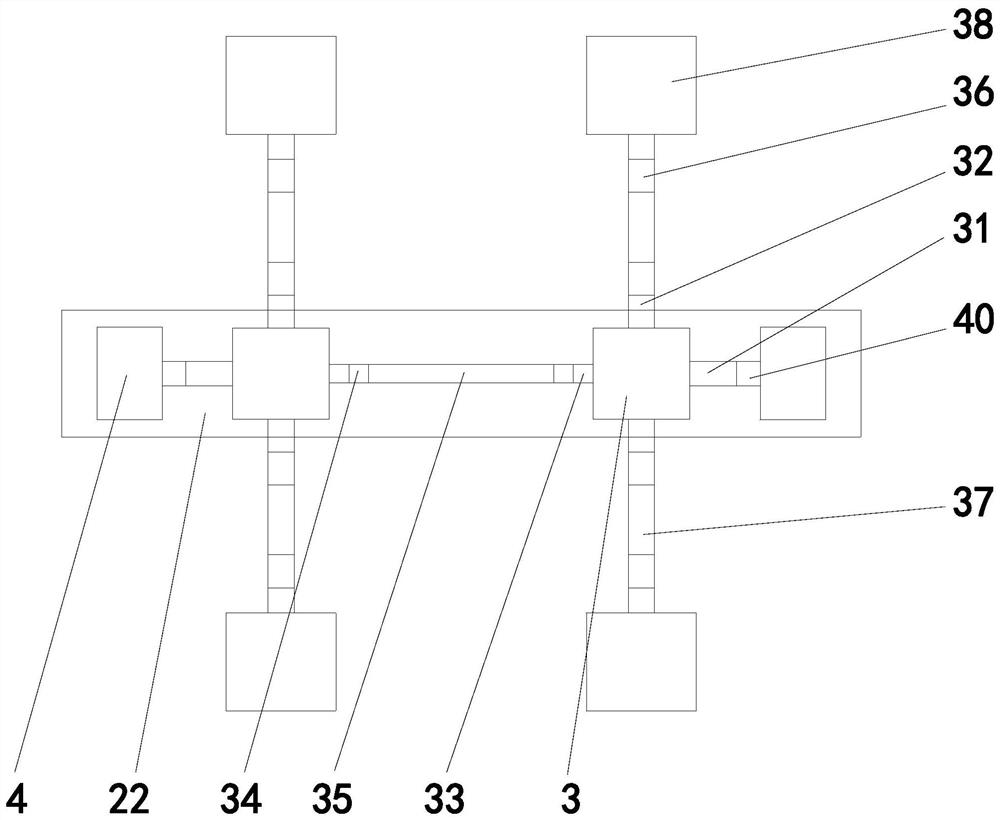

[0016] refer to figure 1 and figure 2 , a dual-motor type dual-axis vibrating screen of the present invention includes a screen box 1, a base 2, a mounting plate 11, a beam 22, a spring set 10, a motor 4, a gear box 3, a vibrator 38, and a first universal coupling 36, the first connecting shaft 37, the second universal joint 34, the second connecting shaft 35, the screen box 1 is installed obliquely, a mounting plate 11 is fixed on both sides of the bottom of the screen box 1, and the bottom of the screen box 1 A base 2 is provided, and several spring groups 10 are installed on the bottom of the screen box 1, and the bottom of each spring group 10 is connected with a support column 25, and the support column 25 is fixed on the base 2, and the base 2 is installed There is a beam 22, and two gear boxes 3 are installed on the beam 22, and each gear box 3 is provided with an input shaft 31, a synchronous shaft 33, and two output shafts 32, and each gear box 3 corresponds to a mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap