Production and spraying equipment of automobile standard component

A technology for automotive standard parts and spraying equipment, which is applied in spray booths, spraying devices, and dispersed particle separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

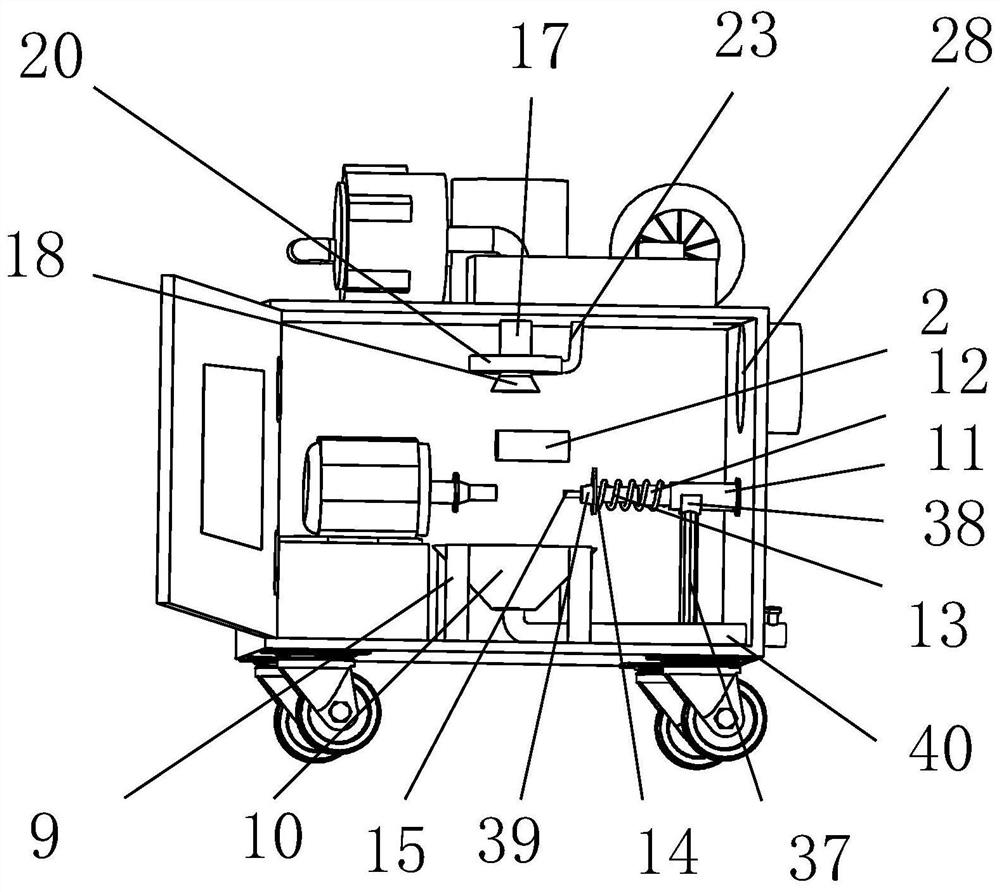

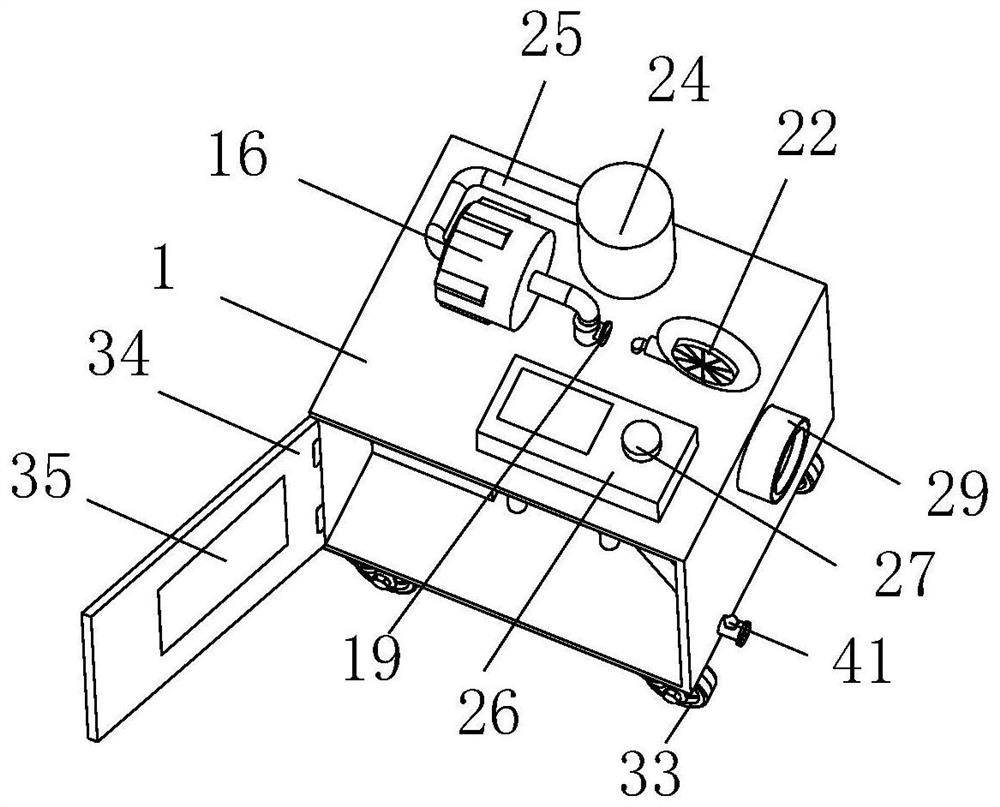

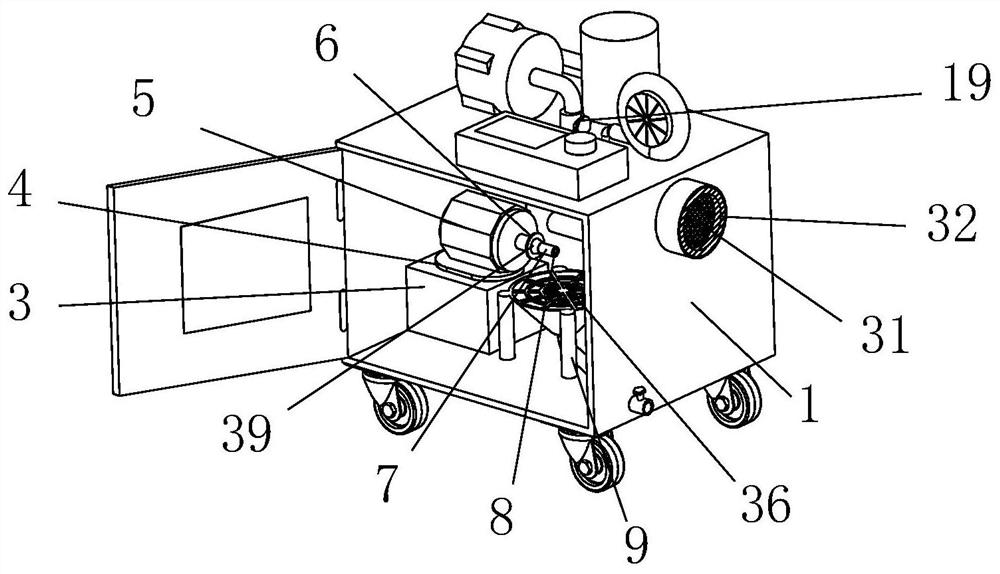

[0030] see Figure 1-6 , the present invention provides the following technical solutions: a spraying equipment for the production of standard parts for automobiles, comprising a chassis main body 1 and an internally threaded cylindrical pin 2, the left side of the bottom plate of the chassis main body 1 is fixedly connected with a loading platform 3, and the upper surface of the loading platform 3 A buffer pad 4 is provided, the buffer pad 4 is an elastic rubber pad, a rotating motor 5 is fixedly installed above the buffer pad 4, the output end of the rotating motor 5 is fixedly connected with a first baffle plate 6, and the right end of the first baffle plate 6 is fixedly connected There is a fixed rod 7, and the internal thread cylindrical pin 2 is arranged on the outer surface of the fixed rod 7, and the right side surface of the fixed rod 7 is provided with a slot 8, and the middle of the bottom plate of the chassis main body 1 is fixedly connected to the support column 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com