Vacuum packaging device capable of monitoring packaging state in real time

A technology of vacuum packaging and real-time monitoring, applied in packaging, transportation packaging, packaging protection, etc., can solve problems such as detection of incapable packaging status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

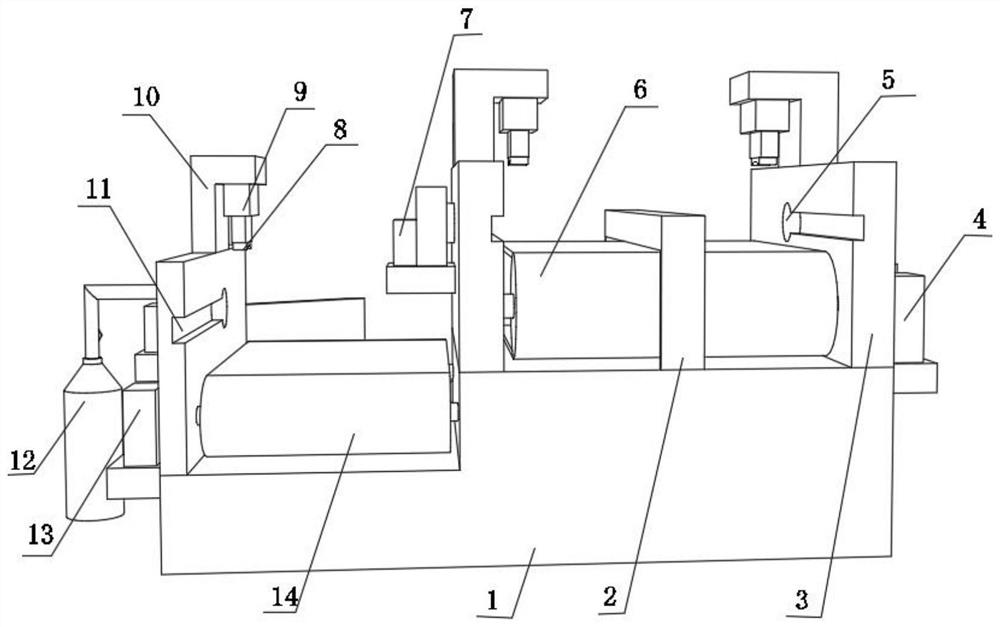

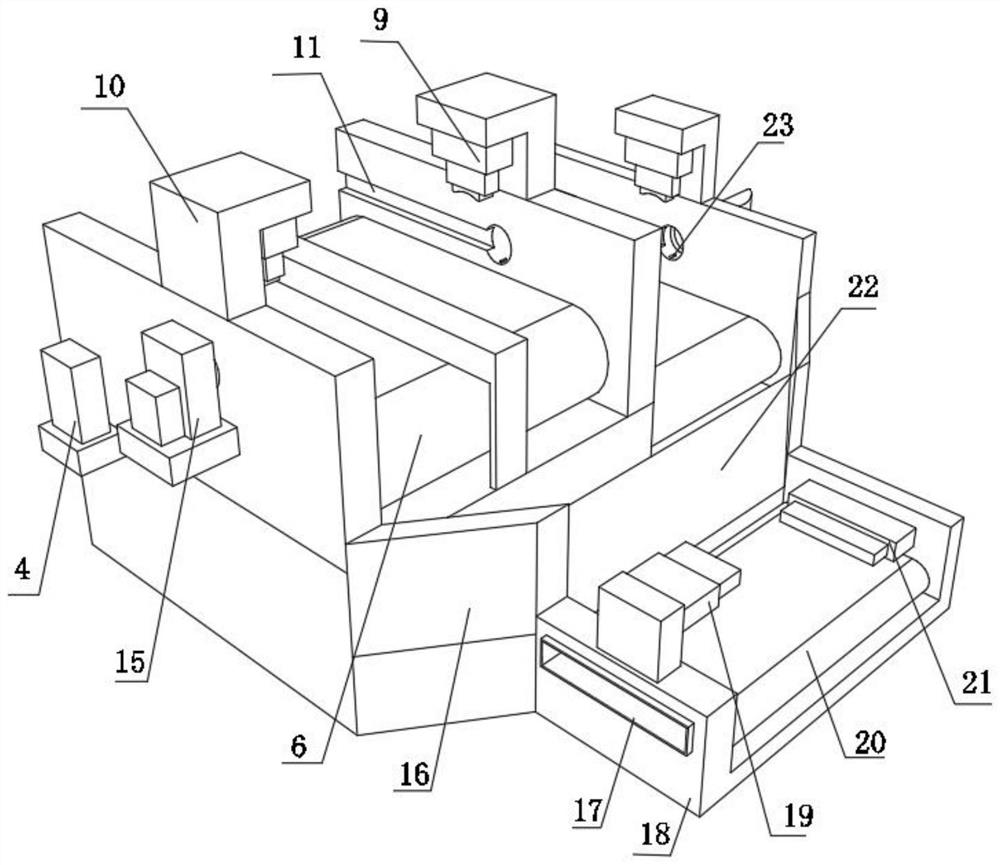

[0031] A vacuum packaging device that can monitor the packaging status in real time, such as Figure 2-5Shown, comprise body 1, one side outer wall of described body 1 is fixed with blanking seat 22 by bolt, and blanking seat 22 is inclined shape, and one side outer wall of blanking seat 22 is fixed with base 18 by bolt, and base 18 The top outer wall is fixed with a support plate by bolts, the outer wall of one side of the support plate is fixed with a second electric telescopic column 19 by bolts, and the bottom outer wall of the second electric telescopic column 19 is fixed with a gas sensor 27 by bolts. The model of the gas sensor 27 is Map -PaK, the signal output end of the gas sensor 27 is electrically connected to the control module, when the vacuum packaging bag to be detected slides down to the top of the base 18 through the inclined unloading seat 22, the switch of the second electric telescopic column 19 is activated to adjust itself Appropriate distance, when the p...

Embodiment 2

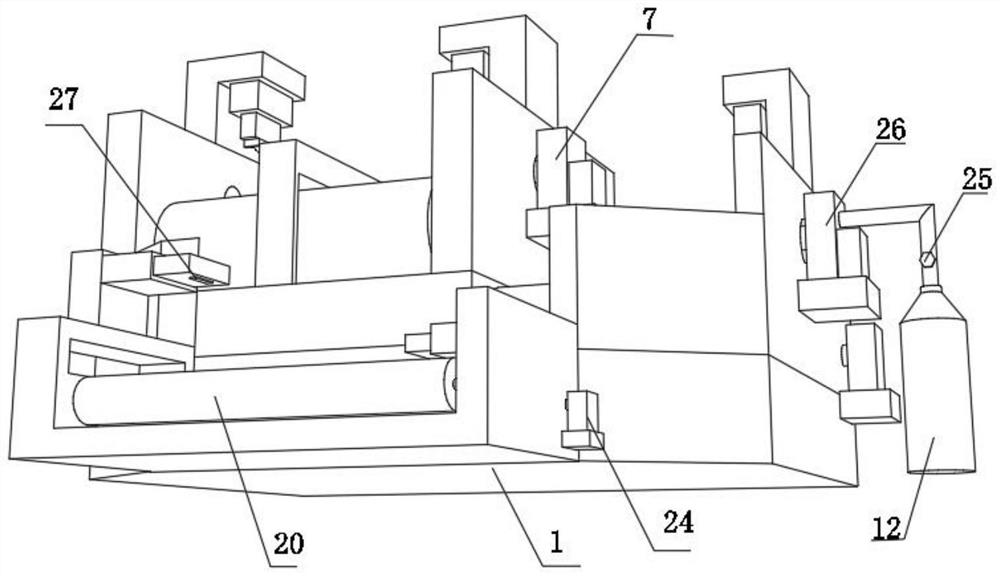

[0040] A vacuum packaging device that can monitor the packaging status in real time, such as Figure 3-5 As shown, in order to supplement the nitrogen to carry out the packaging bag body; this embodiment makes the following improvements on the basis of embodiment 1: one side of the outer wall of the fixing seat 3 is fixed with a fourth support plate by bolts, and the fourth support plate The blower 26 is fixed by bolts, the switch control end of the blower 26 is electrically connected to the control module, the input end of the blower 26 is fixed with a conduit by bolts, and the outer wall of the conduit is fixed with an electric valve 25 by bolts. The switch control end of 25 is electrically connected with the control module, and one end of the conduit is fixed with a nitrogen cylinder 12 through threads, and the material opening enters the operation tank 5, and one end of the material opening touches the collision sensor 23, and the collision sensor 23 transmits a signal to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com