A method for preparing table formwork standard section, long formwork table and laminated plate

A technology of standard joints and laminated panels, applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problem of the decline in the output efficiency of the long mold table production line, the difficulty in grasping the timing of concrete roughening treatment and maintenance, and the lack of roughening treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The embodiment of the present application provides a method for preparing a laminated board, which includes the following steps:

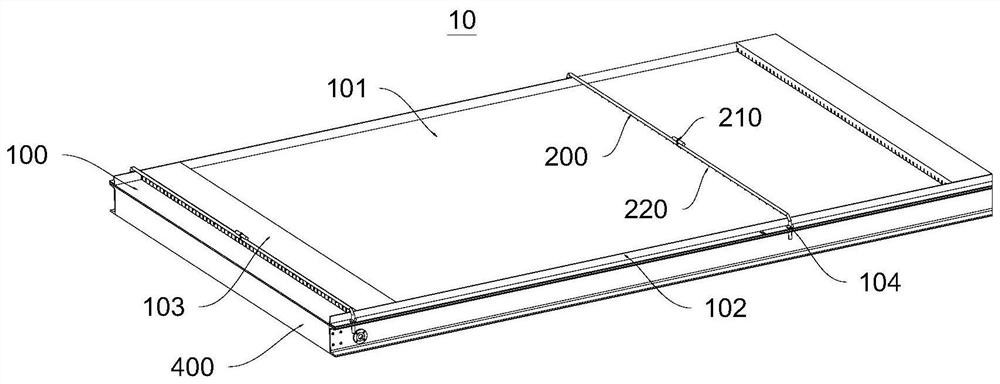

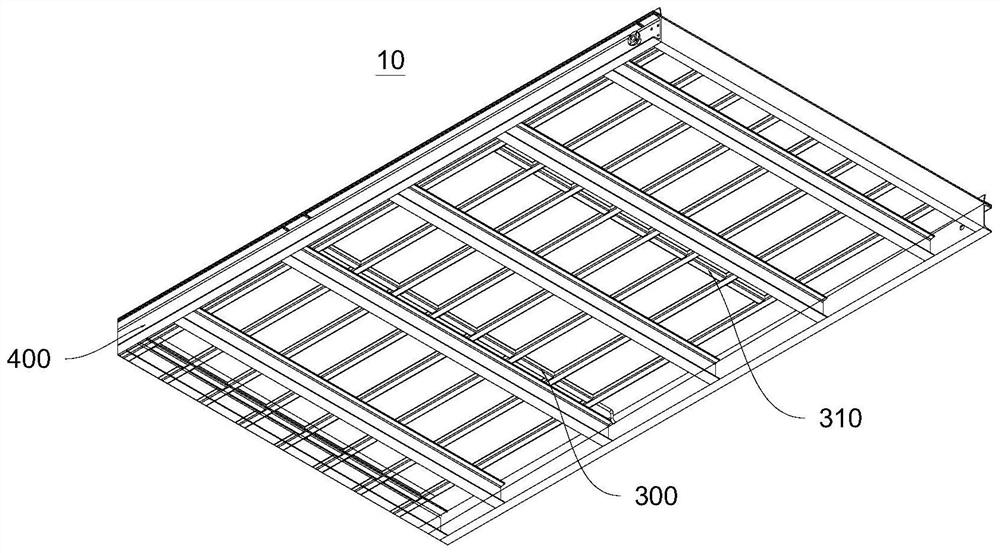

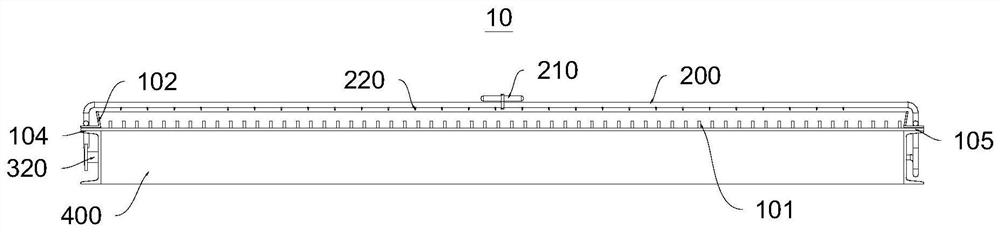

[0094] A 100m long formwork table 20 is adopted, including ten standard table formwork sections 10 of 10m in length, and the concrete on the first section of table formwork standard section 10 will be cured after the placing machine finishes pouring on the first section of table formwork standard section 10 At this time, it is necessary to rotate the installation frame 200 of the first table formwork standard section 10 to rotate the temperature and humidity sensor 210 and multiple nozzles 220 to the upper side of the working surface 101, and the controller can further control the concrete according to the feedback data of the temperature and humidity sensor 210. To maintain the environment, after completing the maintenance of the concrete on the first table formwork standard section 10, roughen the concrete surface. According to the order o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com