Method for gas grading zoning extraction for goaf of working face of single mining thick coal seam

A technology for gobs and working faces, which is applied in the direction of gas discharge, drilling equipment and methods, mining equipment, etc. It can solve the problems of gas exceeding the limit, achieve the effect of reducing the burden and improving the gas drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

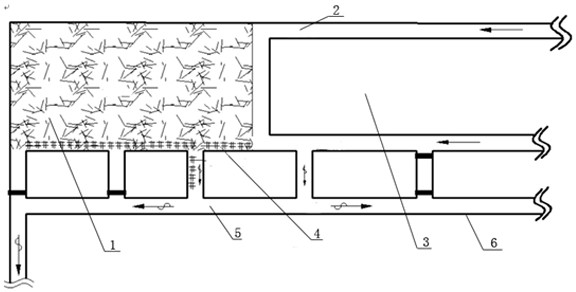

[0022] The present invention optimizes and improves the traditional goaf gas drainage system and technical measures, and its purpose is to extract gas in the goaf in separate sources and zones during the mining of the working face, so as to realize the exhaustion of gas in the goaf , and prevent the upper corner gas from exceeding the limit. The technical scheme of the present invention is: establish three sets of extraction systems on the working face: the coal seam extraction system, the goaf extraction system, and the upper corner extraction system; the mining process of the working face is divided into three stages: the initial mining stage , normal mining stage, and final mining stage; according to the different gas accumulation positions of the source of the goaf, in the three stages of the mining process of the working face, the roof fissure zone of the goaf, the caving zone of the goaf, and the fissure zone of the floor of the goaf are arranged. According to the draina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com