Multi-angle welding machine

A welding machine, multi-angle technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high production labor intensity, occupying horizontal space, unable to realize multi-angle product welding, etc. Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

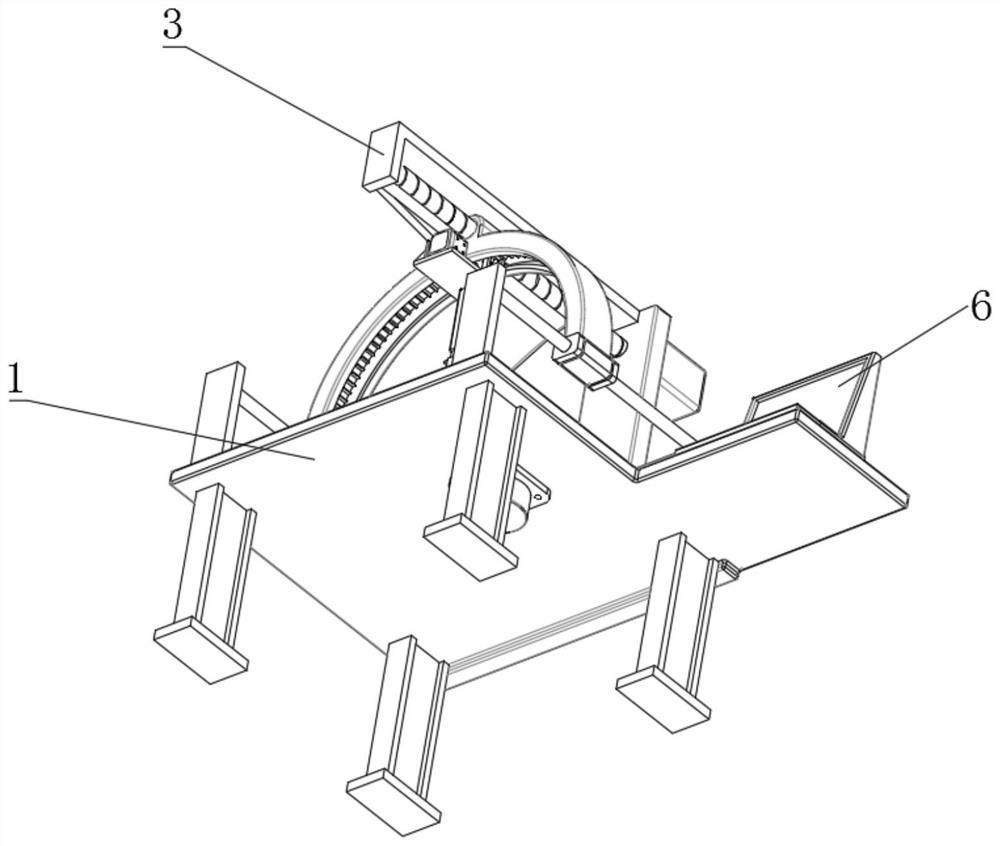

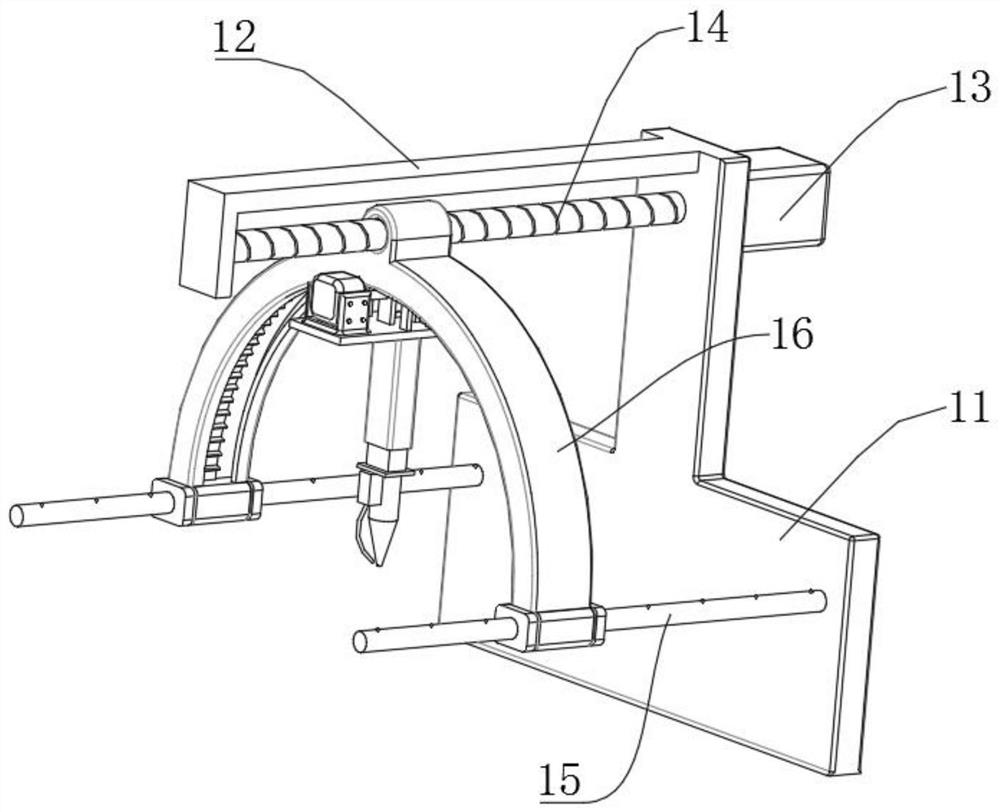

[0031] Such as Figure 1-10As shown, a multi-angle welding machine includes an equipment stand 1 and a welding machine. The models of the welding machine include gas flame, electric arc, laser, etc., and the welding head 2 of the welding machine is installed on the top of the equipment stand 1. The multi-angle adjustment device 3 is installed on the equipment stand 1, the welding machine is installed on the multi-angle adjustment device 3, and the angle adjustment of the welding machine on the XY plane is carried out through the multi-angle adjustment device 3; the rotation mechanism 4 is installed on the equipment stand 1 , the rotating mechanism 4 clamps the welding material and can rotate the material. The gas absorption device 5 is also fixedly connected to the equipment stand 1, and the gas absorption device 5 is connected with the multi-angle adjustment device 3 and the equipment stand. 1 are fixedly connected and communicated, and a controller 6 for controlling the exec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com