Dumpling wrapper extrusion forming equipment

A technology of extrusion molding and dumpling skin, which is applied in the direction of dough extruder, dough molding and slitting combination, etc., can solve the problems of dough sticking, inconvenient collection, and laborious, and achieve the effect of convenient collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

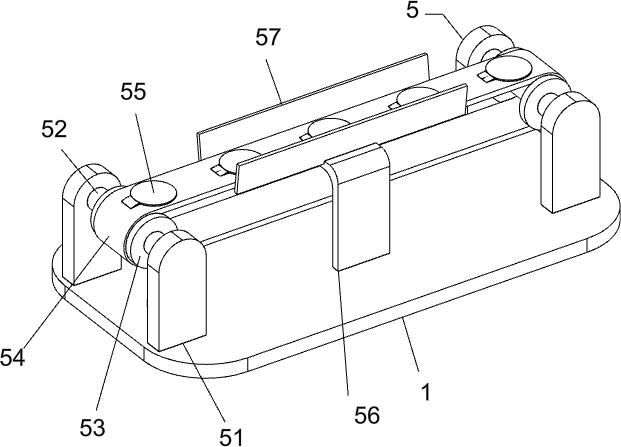

[0024] A dumpling skin extrusion molding equipment, such as Figure 1-5 As shown, it includes a base 1, a dust suction machine 2, a collection bucket 3, an extrusion mechanism 4 and a transmission mechanism 5, the bottom left side of the base 1 is provided with a dust suction machine 2, and the top left side of the base 1 is provided with a collection bucket 3 to collect The bucket 3 is located on the front side of the ash suction machine 2, the collection bucket 3 is detachably connected with the ash suction machine 2, the extrusion mechanism 4 is provided on the top and rear side of the base 1, and the transmission mechanism 5 is provided on the top of the base 1, and the transmission mechanism 5 is located in the extrusion mechanism 4 On the front side, the transmission mechanism 5 is connected with the extruding mechanism 4.

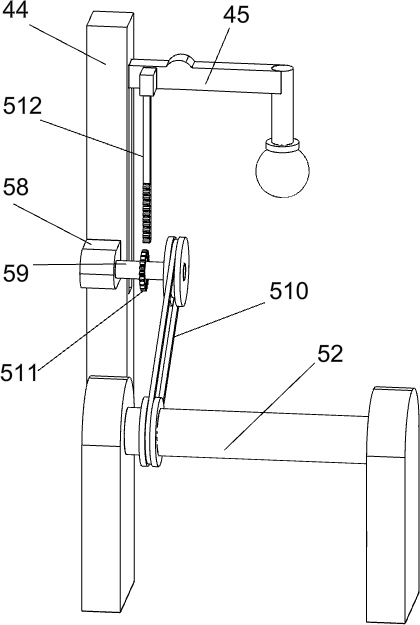

[0025] Extrusion mechanism 4 comprises first chute plate 41, the first slide plate 42, extruding plate 43, the second chute plate 44, the second sli...

Embodiment 2

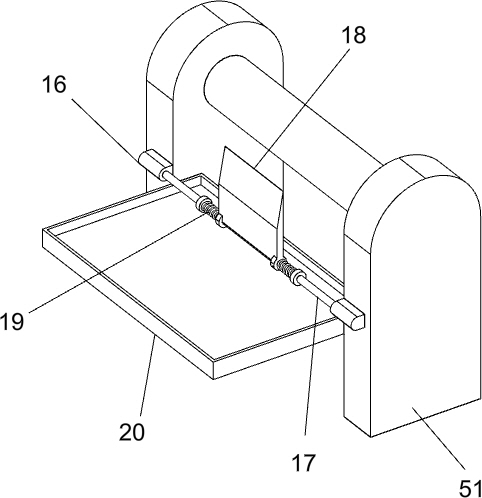

[0031] On the basis of Example 1, such as figure 1 with Figure 5-6 As shown, it also includes a mounting frame 6, a slide bar 7, a first blade 8, a compression spring 9, a reel 10, a connecting plate 11, a slide rail 12, a circular slider 13, a pull wire 14 and a push rod 15, squeeze The bottom left and right sides of the pressing plate 43 are symmetrically provided with mounting brackets 6, and both sides of the mounting frame 6 bottoms on the left and right sides are slidingly provided with slide bars 7, and the insides of the slide bars 7 on the left and right sides are all provided with first blades 8. The first blades 8 on both sides are located at the bottom of the extruding plate 43, and a compression spring 9 is connected between the slide bar 7 and the mounting frame 6. The bottom of the mounting frame 6 on both sides is provided with a winding wheel 10, and the first chute plates 41 on both sides are The top is provided with a connecting plate 11, and the inner fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com