A Combined Precision Control Buffer Device

A buffer device and a combined technology, applied in the direction of spring/shock absorber, low internal friction spring, shock absorber, etc., can solve the problems of limited buffer capacity of a single spring, inability to perform precise control, and large mechanical structure, etc., to achieve Improve the stability, improve the simplification of the machine structure, and reduce the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the following description, many specific details are set forth in order to facilitate a full understanding of the present invention, but the present invention may also

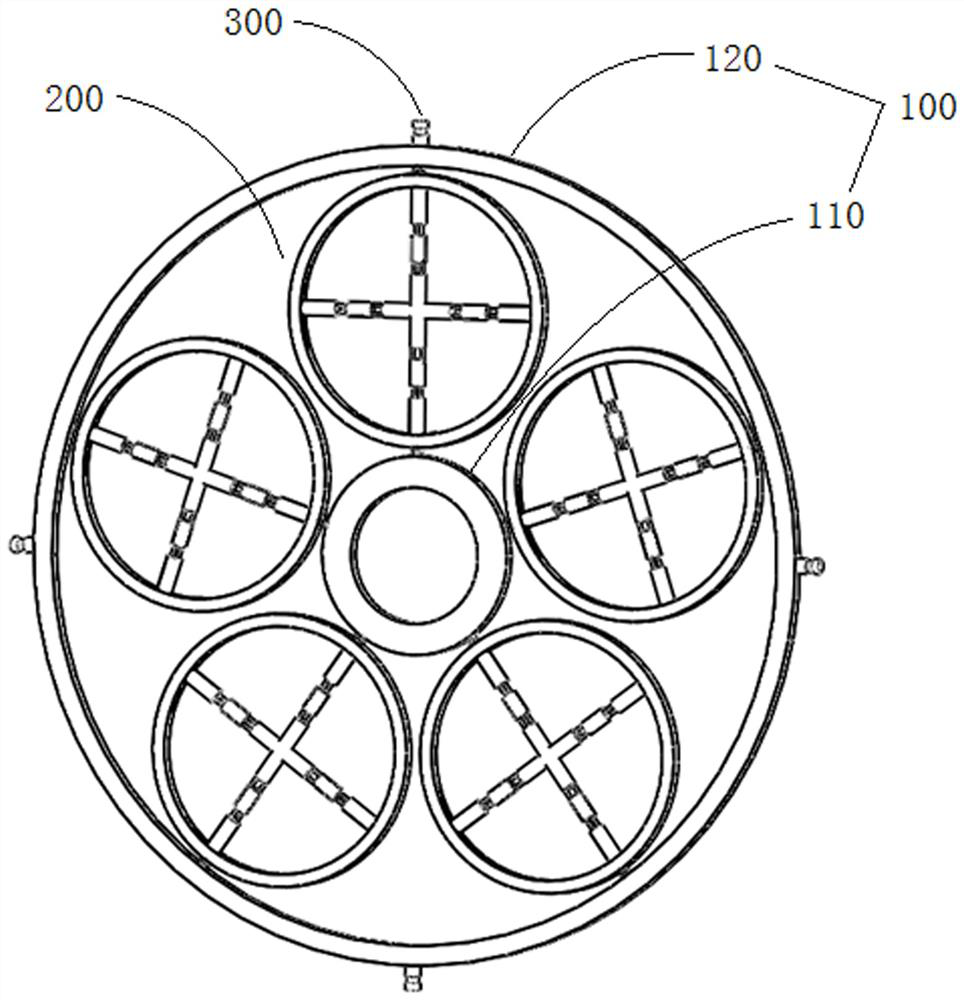

[0049] Fig. 1 shows a three-dimensional schematic diagram of the combined precise control buffer device.

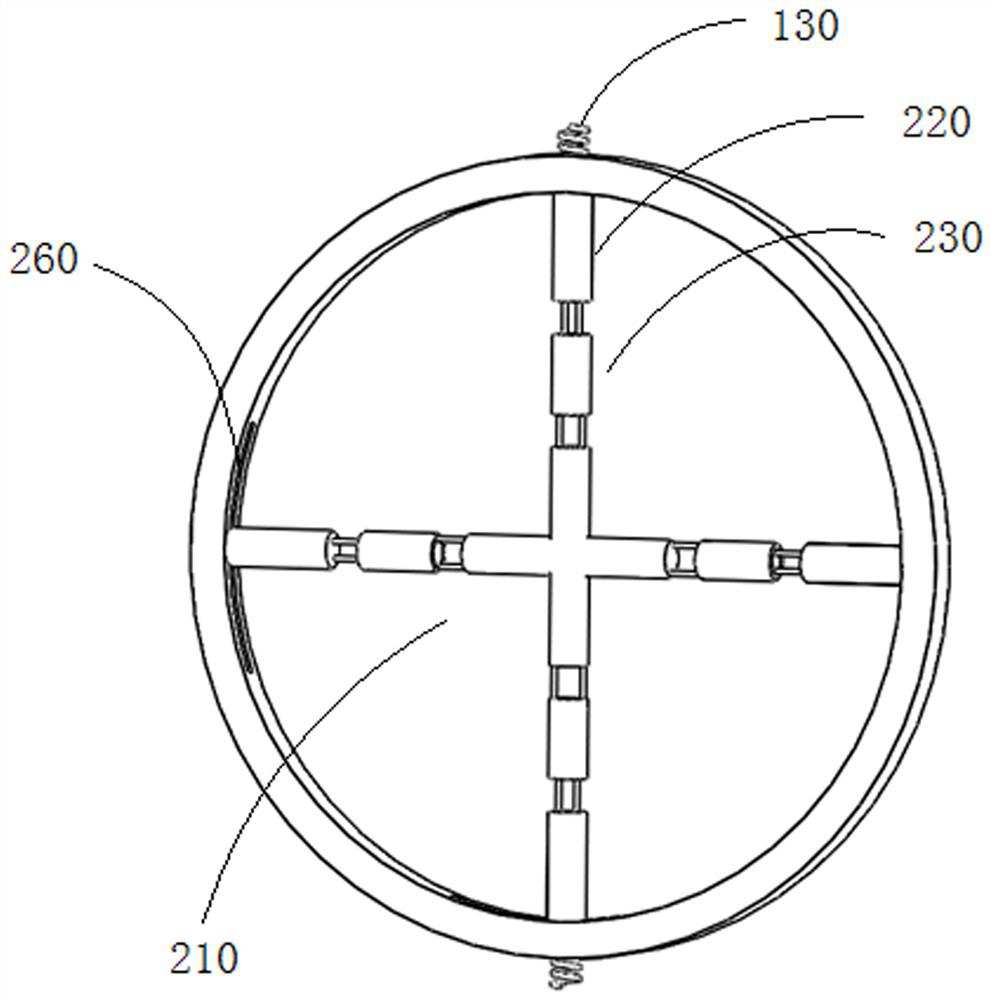

[0051] FIG. 2 shows a three-dimensional enlarged structural schematic diagram of the secondary control ring 200 in the combined precise control buffer device.

[0052] As shown in FIG. 2, the secondary control ring 200 is provided with at least one elastic mechanism 210, and the two ends of the elastic mechanism 210 are respectively

[0053] The inner wall of the secondary control ring 200 is preferably provided with a slide rail 260, and one end of the elastic mechanism 210 is slidably connected to the slide rail 260.

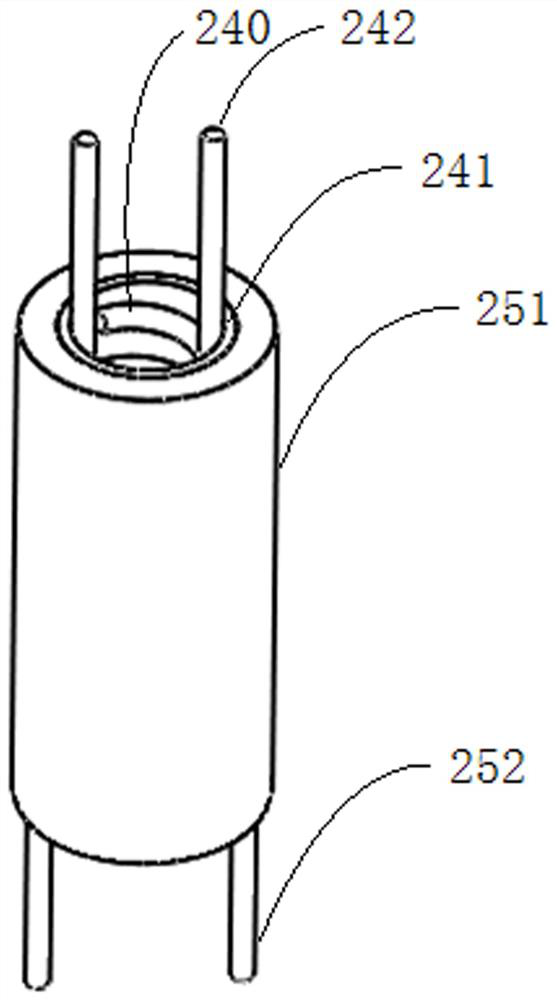

[0056] As shown in FIG. 3 and FIG. 4, the elastic element 230 includes an inner compression spring 240, an inner casing 241, an outer

[0057] In order to make the telescopic bufferi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com