Clamping and mortising slotting device for bird cage

A technology of birdcages and clamping blocks, which is applied in slotting machines, mortising machines, sugarcane machining, etc., and can solve problems such as high technical requirements and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

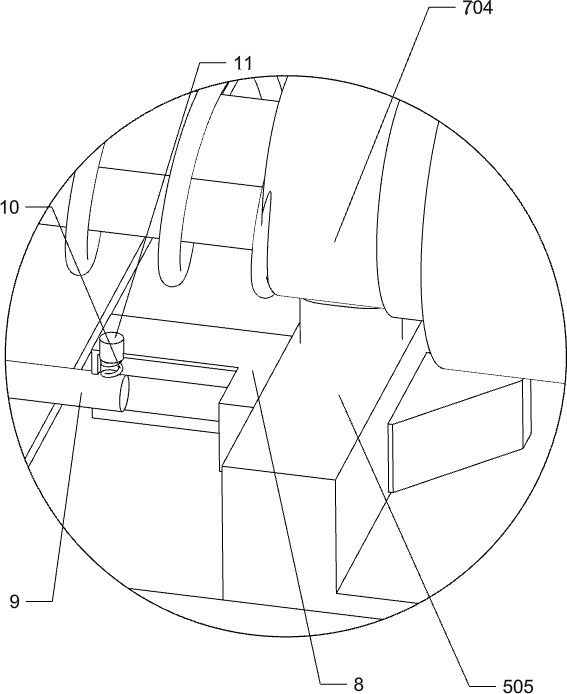

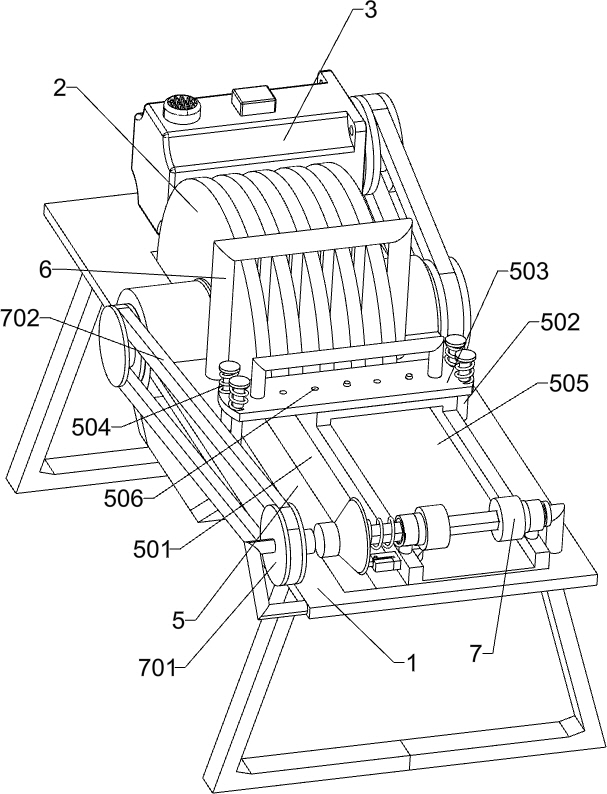

[0025] A kind of locking and slotting device of birdcage, such as Figure 1-2 As shown, it includes a base 1, a tooth saw 2, a motor 3 and a rotating shaft 4. The rear side of the top of the base 1 is rotatably connected to the rotating shaft 4. The rotating shaft 4 is connected to the tooth saw 2. The motor 3 is installed on the rear side of the top of the base 1. The output shaft of 3 is connected with the rotating shaft 4 by belt and pulley transmission, and also includes adjustment mechanism 5 and limit mechanism 6, and base 1 front side is provided with adjustment mechanism 5, and base 1 middle part is provided with limit mechanism 6.

[0026] The adjustment mechanism 5 includes a guide rod 502, a top plate 503, a pressure spring 504, a fixed plate 505 and a block 507. The front side of the top of the base 1 has a chute 501, and the middle part of the top of the base 1 is connected with a guide rod 502 on both sides. A top plate 503 is slidably connected between the side ...

Embodiment 2

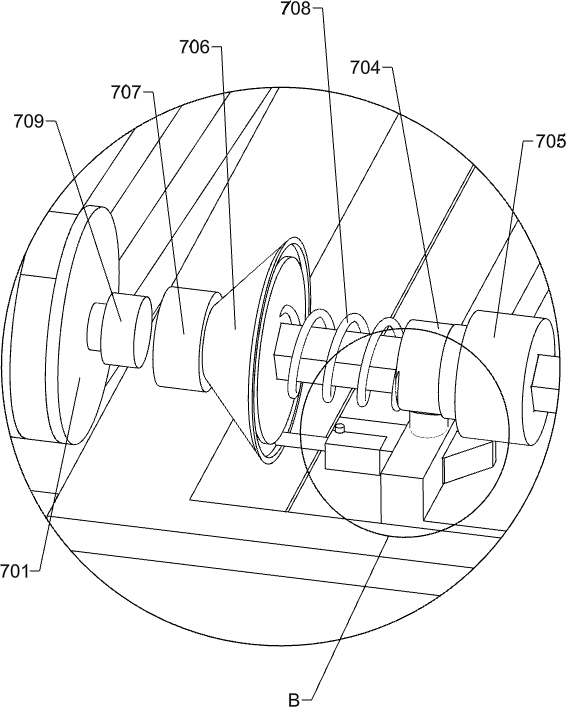

[0030] On the basis of Example 1, such as Figure 1-4 As shown, it also includes a transmission mechanism 7 and a clamping mechanism. The transmission mechanism 7 is provided on the front side of the top of the base 1 , and a clamping mechanism is provided between the fixed plate 505 and the transmission mechanism 7 .

[0031] Transmission mechanism 7 comprises sprocket 701, chain 702, hexagonal bar 703, axle sleeve 704, roller 705, cone 706, first magnet 707, back-moving spring 708 and second magnet 709, base 1 top front side and rotating shaft 4 are connected with a sprocket 701, a chain 702 is wound between the two sprockets 701, a hexagonal rod 703 is connected to the right front side of the top of the base 1, and a shaft is connected to the left and right sides of the top front of the fixed plate 505. Sleeve 704, shaft sleeve 704 and hexagonal rod 703 rotate and cooperate, hexagonal rod 703 and shaft sleeve 704 slide fit, hexagonal rod 703 left and right sides are sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com