Manual threaded hole tapping tool and method

A tapping thread and tooling technology, applied in the direction of tangent devices, manufacturing tools, metal processing equipment, etc., can solve problems such as easy to break taps, difficult to screw in screws, uneven technical level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

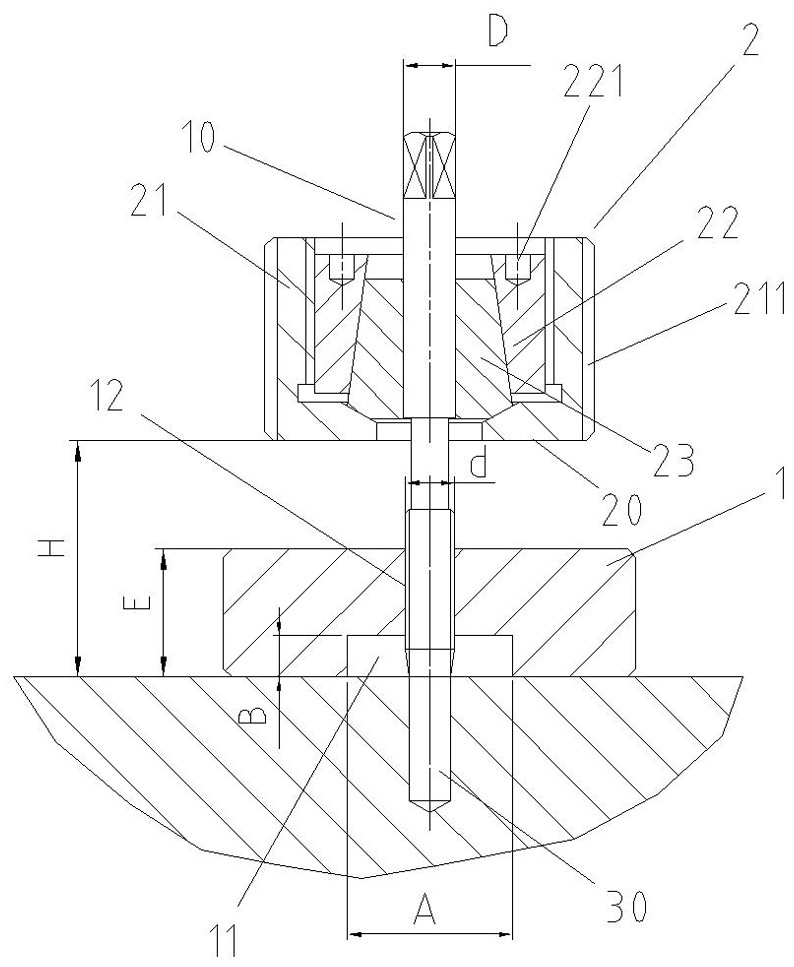

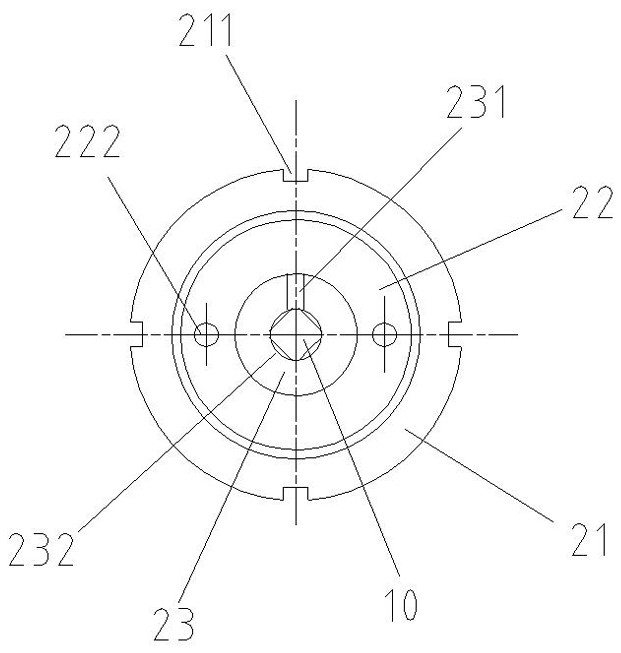

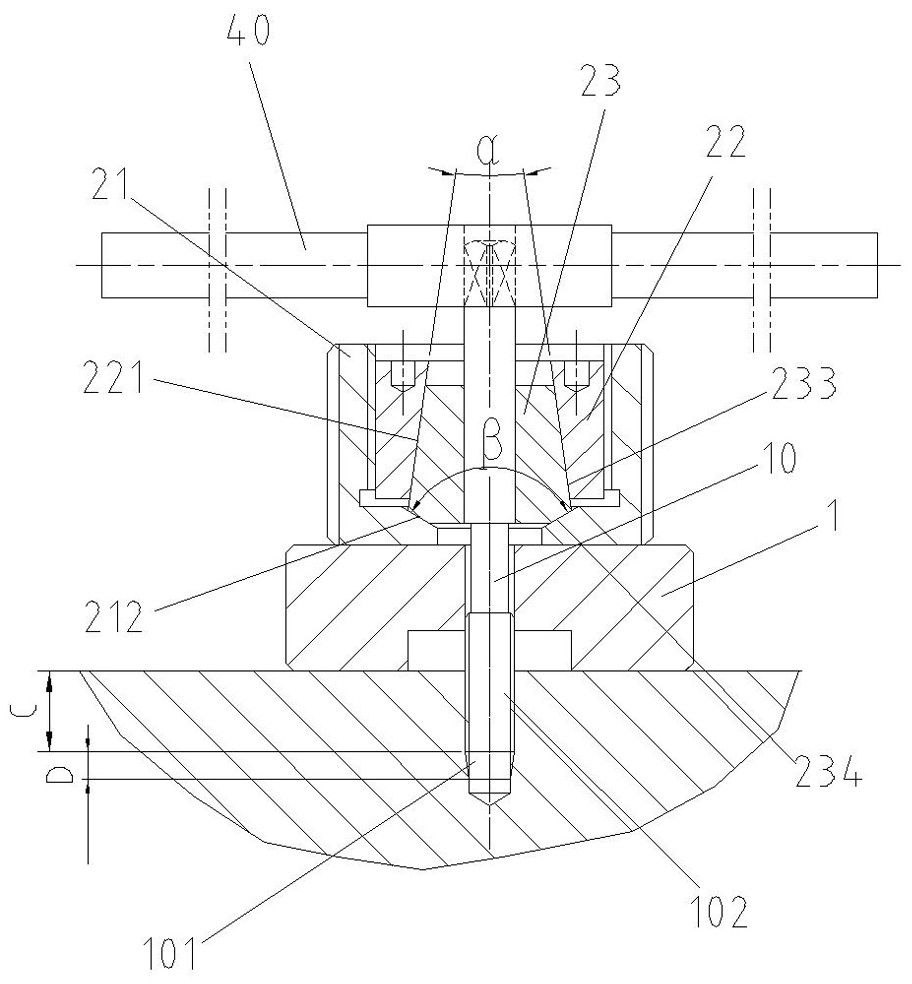

[0021] Such as Figure 1 ~ Figure 3 As shown, the present embodiment includes a positioning block 1 and a limit sleeve assembly 2, the positioning block 1 is a cuboid, and the lower side is provided with a lower through groove 11, and the center of the positioning block 1 is provided with a guide hole 12 connected with the lower through groove 11. The hole 12 is in clearance fit with the outer circle of the tap 10 , and the lower end of the tap 10 passes through the guide hole 12 . The guide hole 12 can make the tap 10 maintain the verticality between the threaded hole and the base surface during the tapping process. The width A of the lower through groove 11 is 3.3 times the outer diameter d of the tap, and the height B=0.9 times the outer diameter d of the tap. When tapping starts, the lower through groove 11 is convenient for observing whether the head of the tap 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com