Rotor blade of wind turbine, having splitter plate

A technology of rotor blades and deflectors, applied in the field of optimizing the rotor blades, can solve problems such as increased noise emission, increased air resistance, and inability to achieve lift, and achieves the effect of easy installation and small transportation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] figure 1 A schematic diagram of a wind energy installation according to the invention is shown. The wind energy installation 100 has a tower 102 and a pod 104 on the tower 102 . An aerodynamic rotor 106 with three rotor blades 108 according to the invention and a spinner 110 is provided on the pod 104 . The aerodynamic rotor 106 is set in a rotational motion by the wind during operation of the wind power plant and thus also rotates the electric rotor or rotor of a generator directly or indirectly coupled to the aerodynamic rotor 106 . The generator is disposed in the pod 104 and generates electrical power. The pitch angle of the rotor blades 108 can be varied by a pitch motor at the rotor blade root of the respective rotor blade 108 .

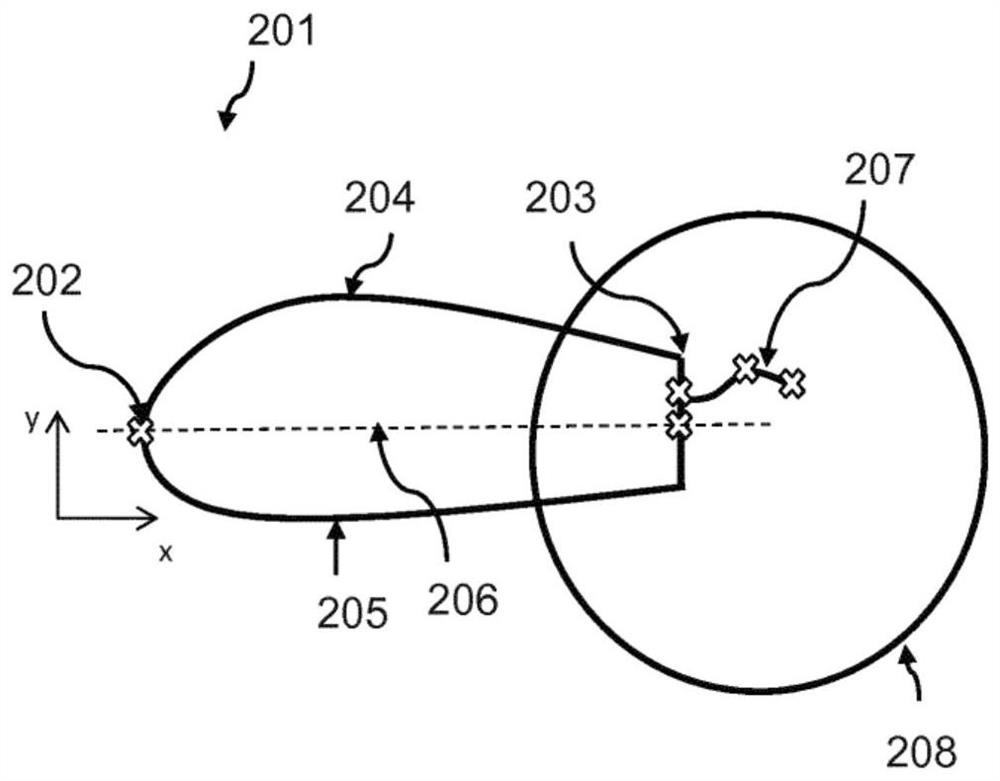

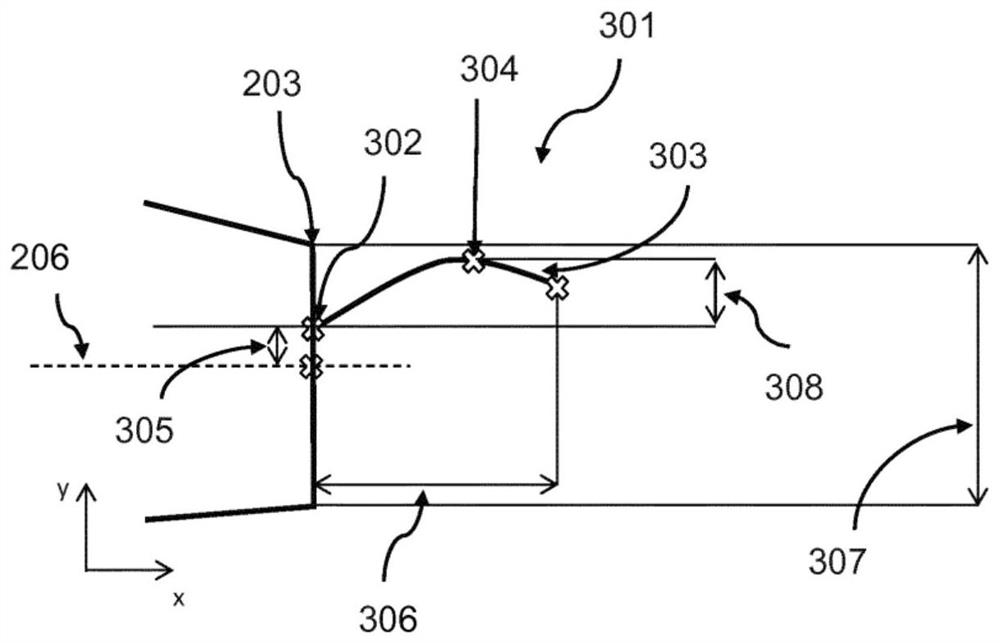

[0044] figure 2 A profile section through a rotor blade of a wind energy installation 106 is schematically shown. In this case, the rotor blade 201 has a contour bead 202 and a trailing edge 203 . For this profile, the trailing ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com