Positioning device for automatic feeding of metal tensile test robot, and feeding method

A tensile test and automatic feeding technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., to achieve the effects of reducing manual labor intensity, simple and reliable mechanism, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the positioning device for automatic feeding of the metal tensile test robot proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , structure, feature and effect thereof, detailed description is as follows.

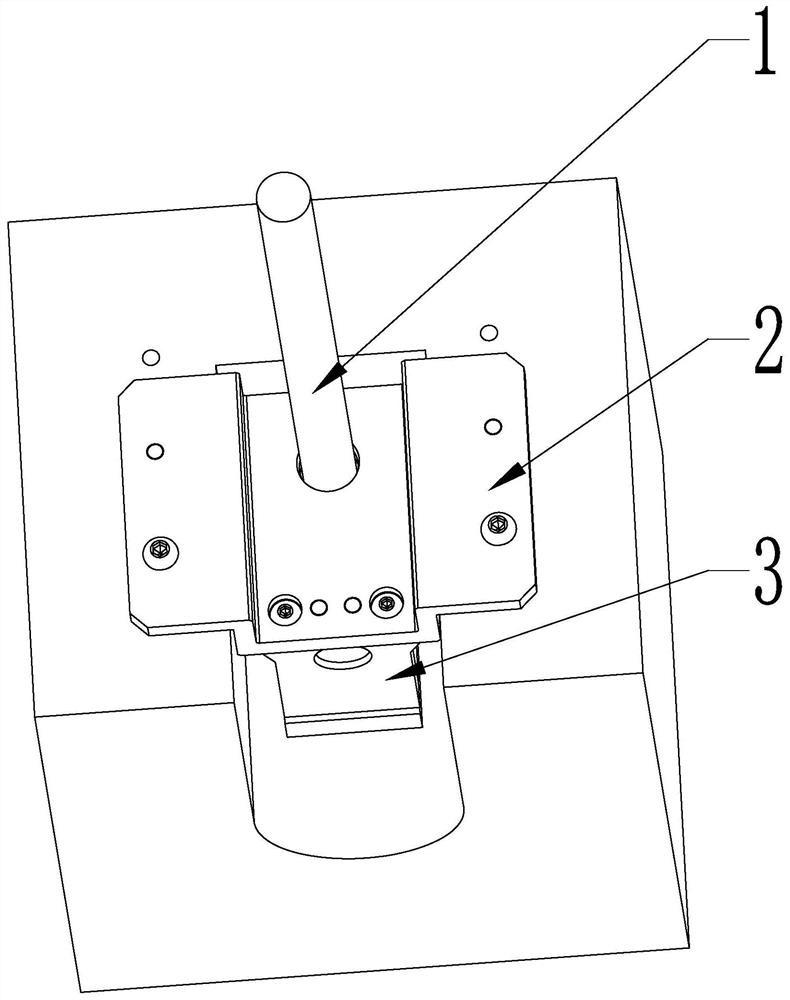

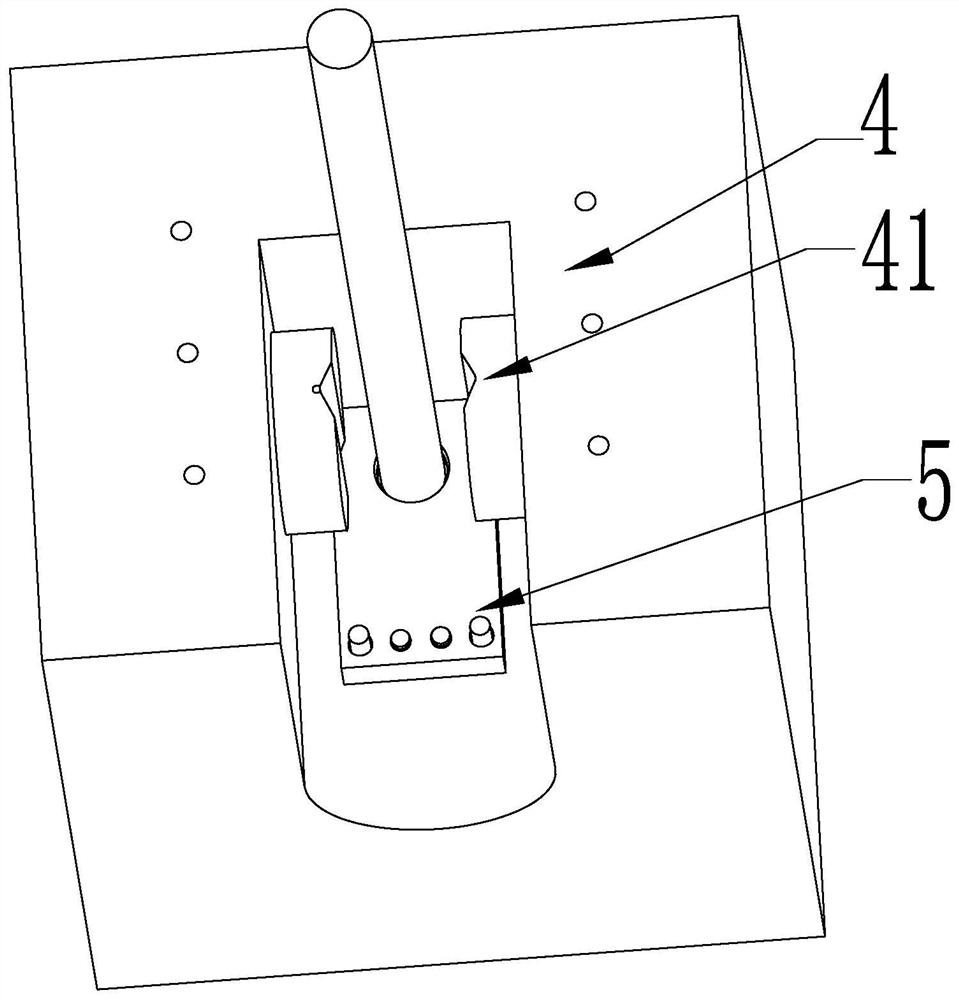

[0028] see figure 1 with figure 2 , which is a structural schematic diagram of a positioning device for automatic feeding of a metal tensile test robot in the present invention, the positioning device includes a clamp 4, and the positioning base 5 at the bottom of the clamping cavity of the clamp 4 is provided with a bar for the lower end of the rod 1 to extend into. The first guide hole with the upper end open and the lower end closed to realize the positioning of the lower end of the bar, the positioning plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com