Easy-to-demold lower ejection device for demolding and unloading of die forgings of screw press

A technology of screw press and ejector device, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as reduced production efficiency, inconvenient separation, and inconvenient product collection. , to achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

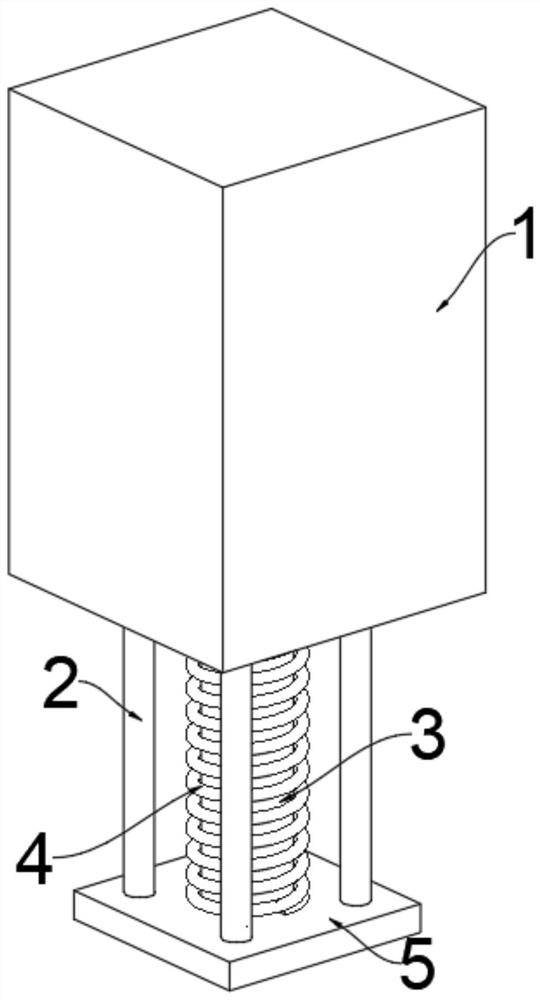

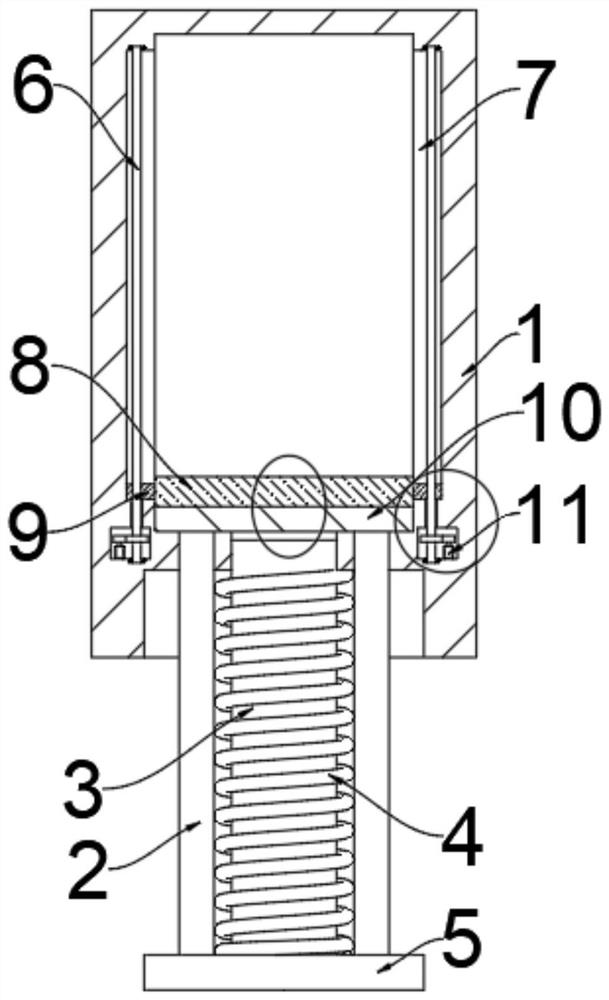

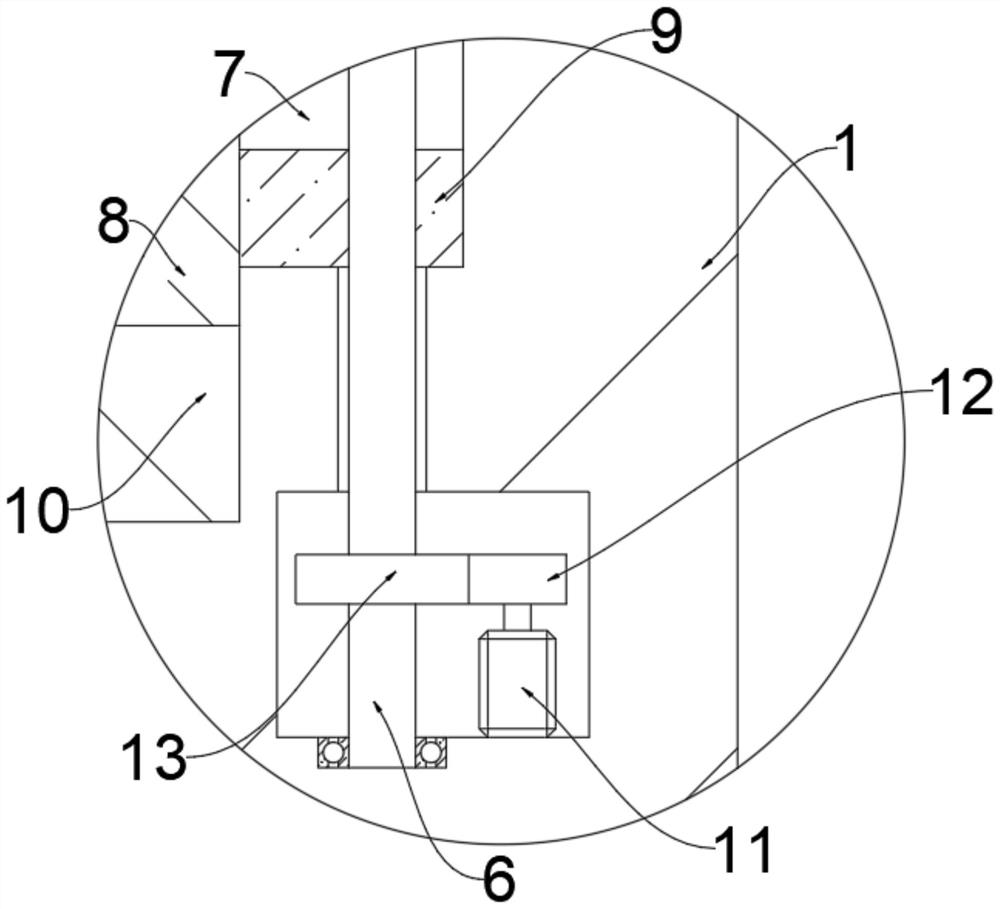

[0023] see Figure 1 to Figure 4 , an embodiment provided by the present invention: an easy-release lower ejecting device for screw press die forging unloading, including a main casing 1, and a blanking plate 5 is installed below the main casing 1 , it is convenient to separate the formed forging from the mold, and it is convenient to collect. The upper end surface of the blanking plate 5 is evenly equipped with four connecting columns 2, and the middle of the four connecting columns 2 is provided with a blanking spring 4, which can pass through the blanking plate. 5 The effect of exerting force on the forging attached to the surface of the mold makes the forging sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com