Truck with automatic loading device

A technology for automatic loading and trucking, which is applied to the arrangement of vehicles with cranes, motor vehicles, loading and unloading vehicles, etc. It can solve the problems of inability to complete the placement of goods, reduce labor intensity, and narrow application range, so as to reduce manpower and labor intensity , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and the The descriptions and diagrams are illustrative in nature and not limiting of the invention.

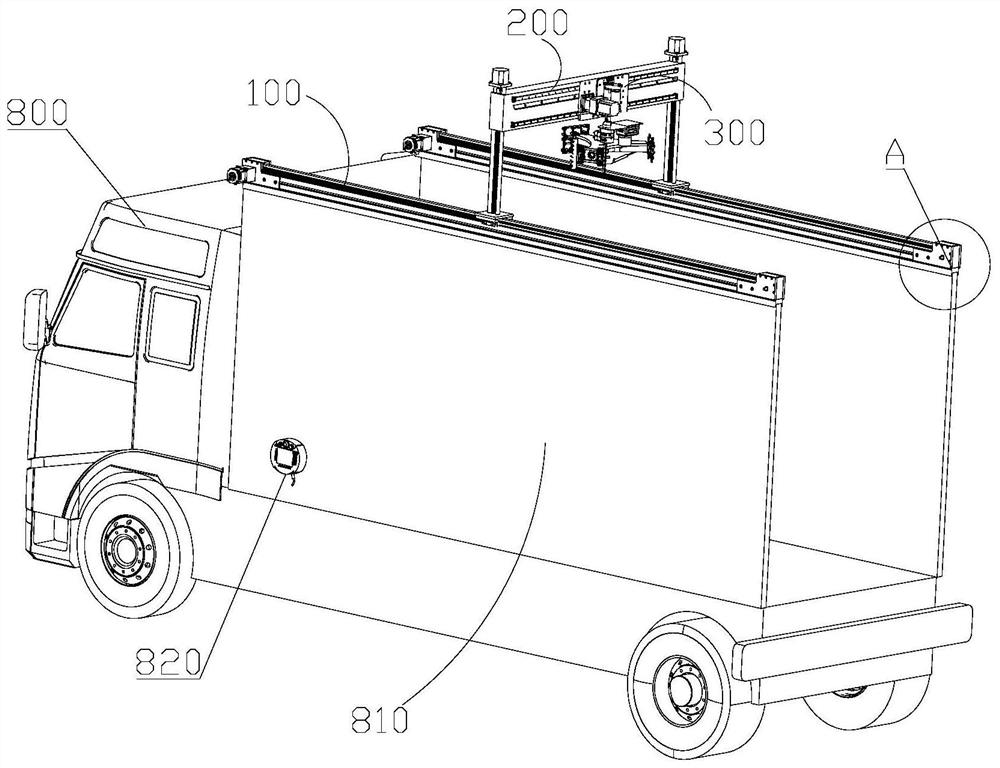

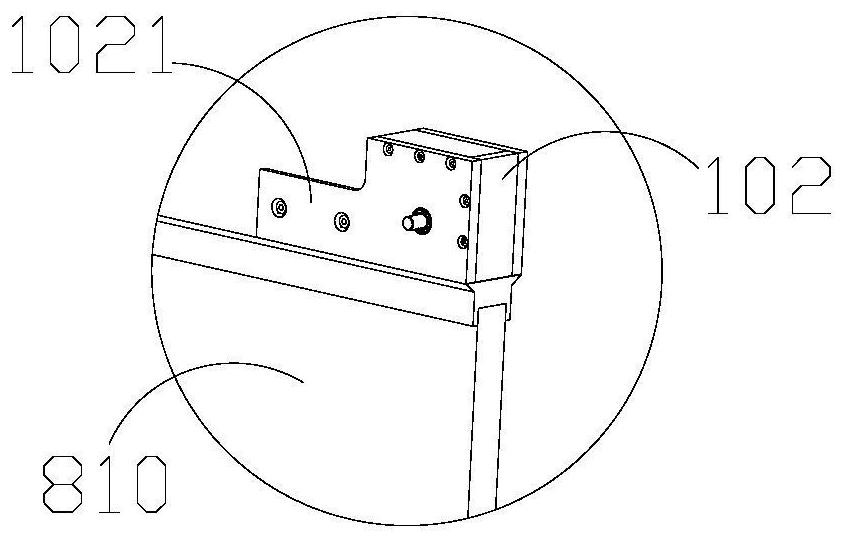

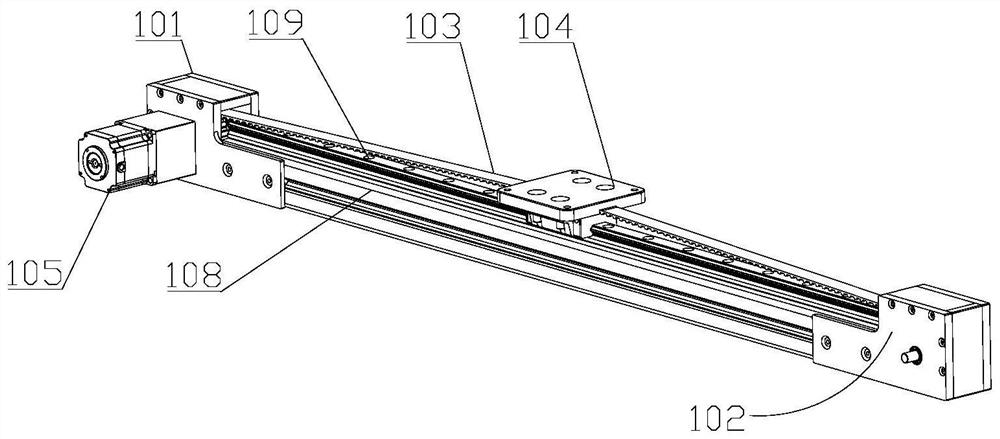

[0051] combine Figure 1-Figure 34 The truck of the automatic loading device according to the present invention includes a car body 800 and a compartment 810 arranged on the car body 800, and the compartment 810 is also provided with an automatic loading device, and the automatic device includes a control device 820, a first direction movement The mechanism 100, the second direction movement mechanism 200 and the third direction movement mechanism 300, the end of the third direction movement mechanism 300 is provided with a grasping structure 400;

[0052] The first directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com