Warehouse lifting door and distribution robot

A technology for lifting doors and warehouses, which is applied to door/window accessories, door leaves, windows/doors, etc. It can solve the problems of large projection area, high requirements for container shipping distance, and long distance, so as to prevent the loss of goods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

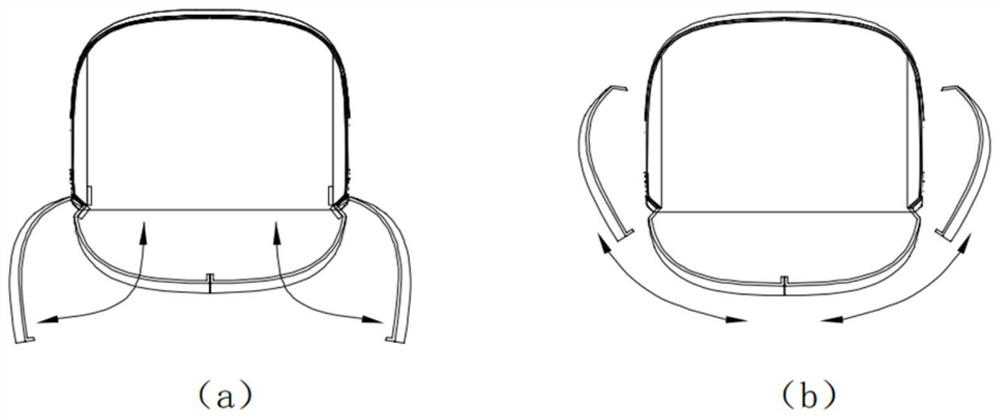

Method used

Image

Examples

Embodiment 2

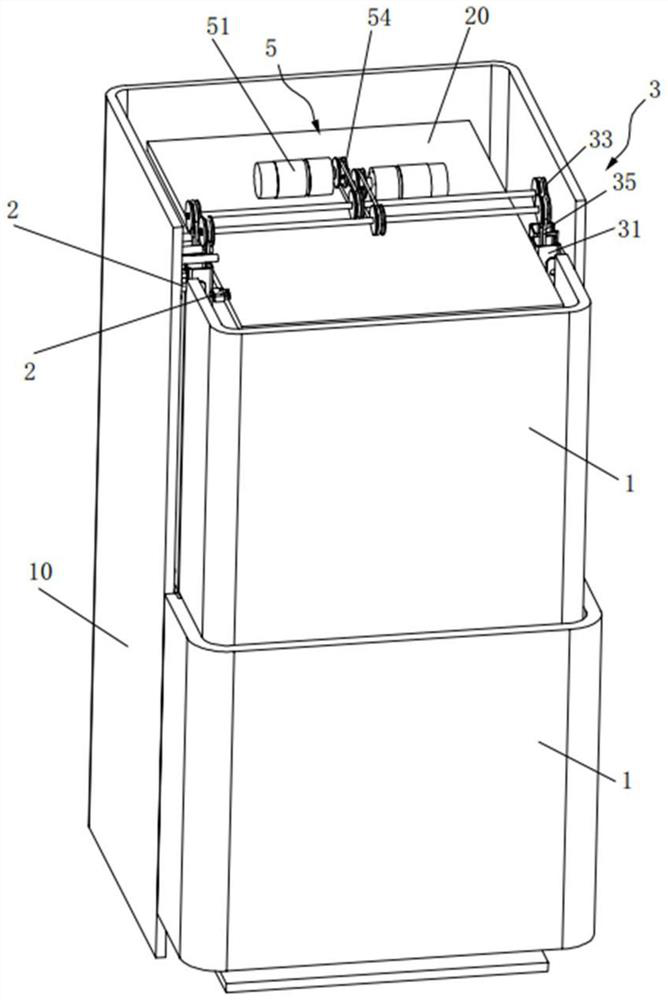

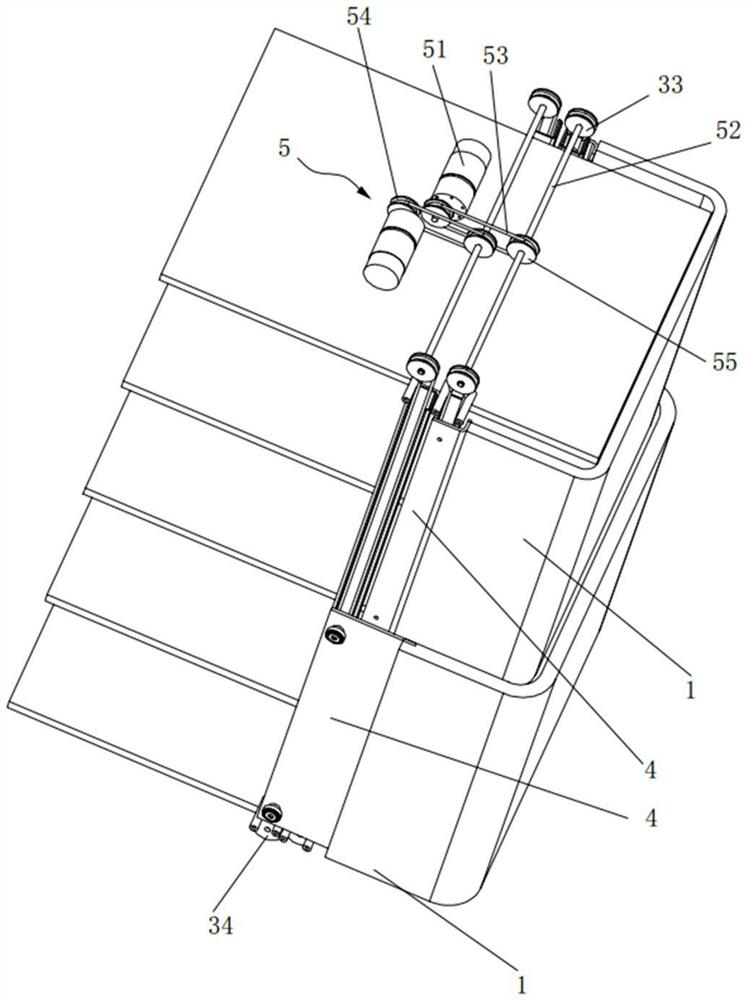

[0057] In this embodiment, the distribution robot includes a housing, a partition and a lift door of the warehouse. The warehouse is formed inside the housing, the lift door of the warehouse is located outside the housing, and the partition is arranged in the warehouse to divide the warehouse into multiple sub-warehouses. The warehouse lifting door includes a plurality of door bodies and a plurality of lifting components. Among them, the multiple doors are mutually misaligned and parallel to the surface of the warehouse opening; the lifting components are respectively connected to the multiple doors, and are used to drive the multiple doors to open and close independently in the respective operating spaces along the vertical direction to the warehouse opening . As for the setting of the limit switch, the limit switch is not provided on the partition board relatively to the middle layer, and the above-mentioned limit switch is set on the other partition boards. position.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com