Grid ruler for grid spraying and scribing

A technology of grid and main board, applied in the field of grid ruler, can solve the problems of slow speed and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, specific embodiment is further described:

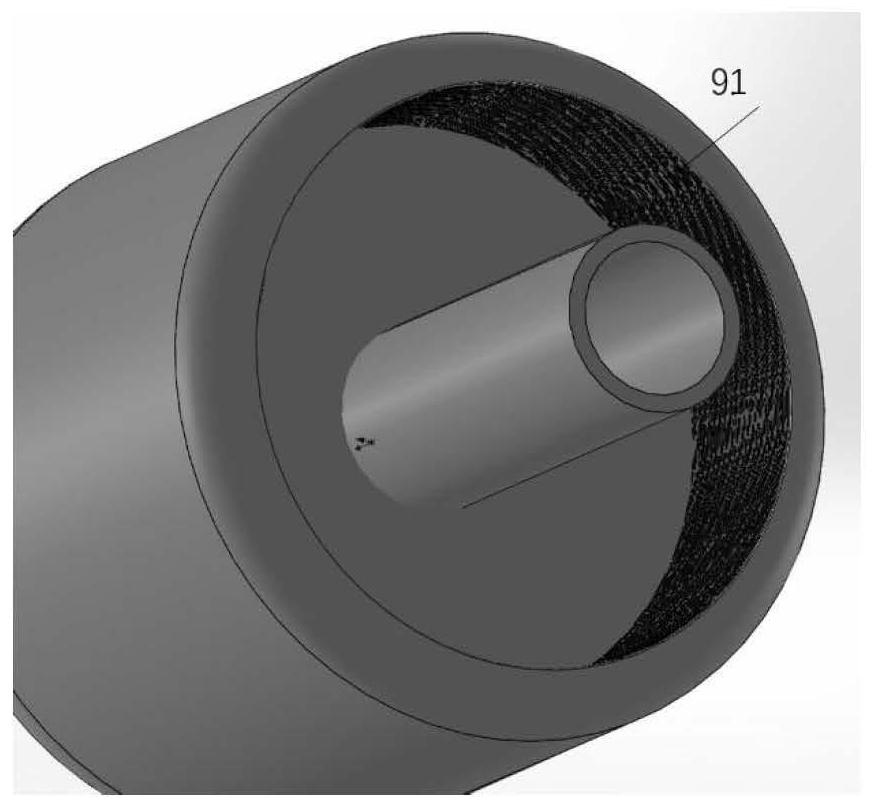

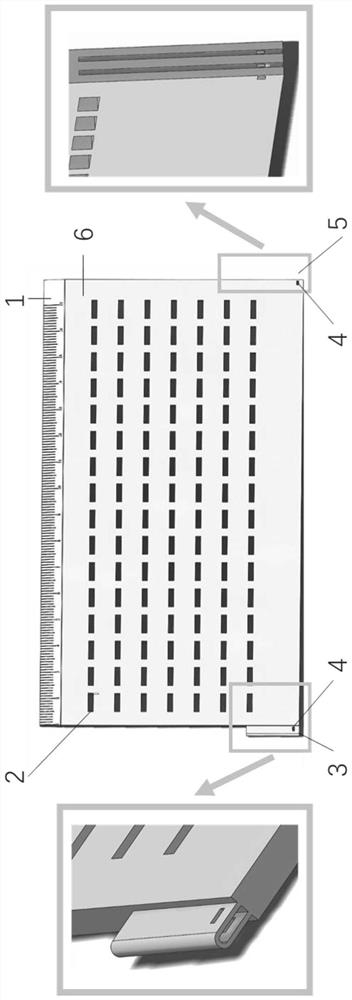

[0032] The grid ruler of the present invention is used in combination with another special tool, the grid spray tank, to realize grid painting that is efficient, accurate and can save paint. Figure 1-Figure 4 is the grid ruler part, Figure 5-Figure 11 Spray tank sections for grids with exchangeable spray heads, Figure 12 Draw a schematic diagram of the method for the mesh.

[0033] grid ruler

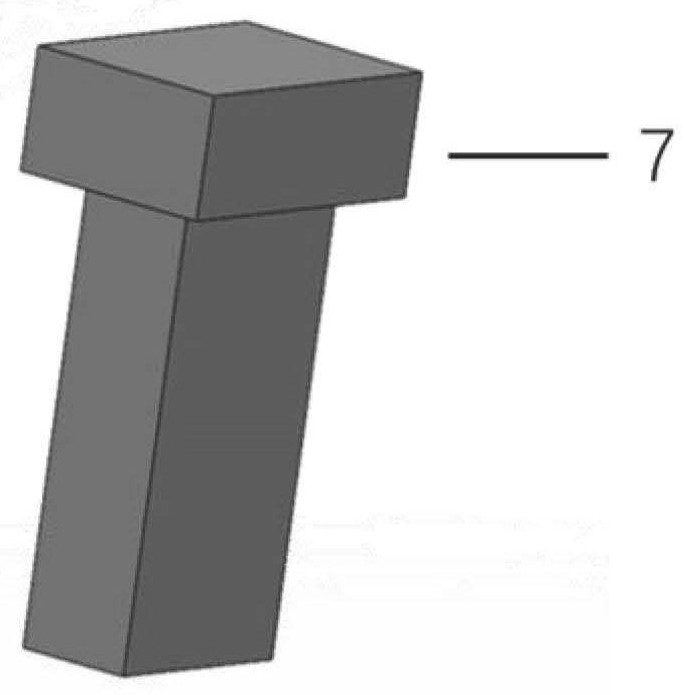

[0034] The grid ruler is realized in the following way: construct a grid ruler, including a measuring section 1, a hole array 2, a left connector 3, a connecting hole 4, a right connector 5, a main board 6, and a special pin 7.

[0035] The measurement section 1 is located on the main board 6. From left to right, the scale is from 0 to 17cm. The scale line at each full centimeter is the longest, and the length of the scale line at every 5mm scale is second, which is convenient for ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com