A target rotation detection method suitable for manipulator in-hand operation

A technology of target rotation and detection method, applied in the field of robots, can solve the problems of complex vision processing algorithm, unfavorable integration of software and hardware of robot control system, unable to meet the requirements of rotation detection, etc., to achieve the effect of improving ability and avoiding operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

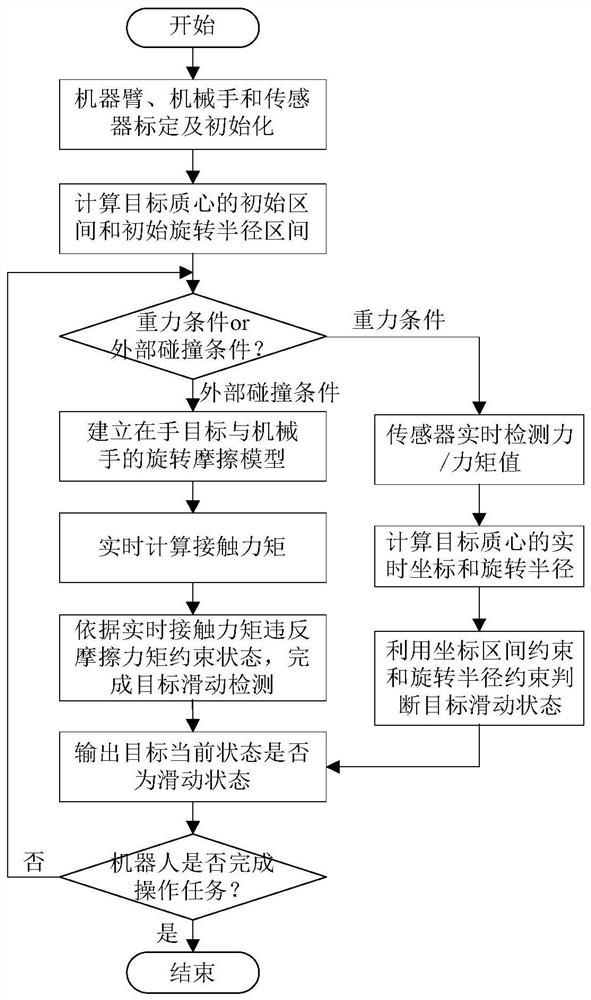

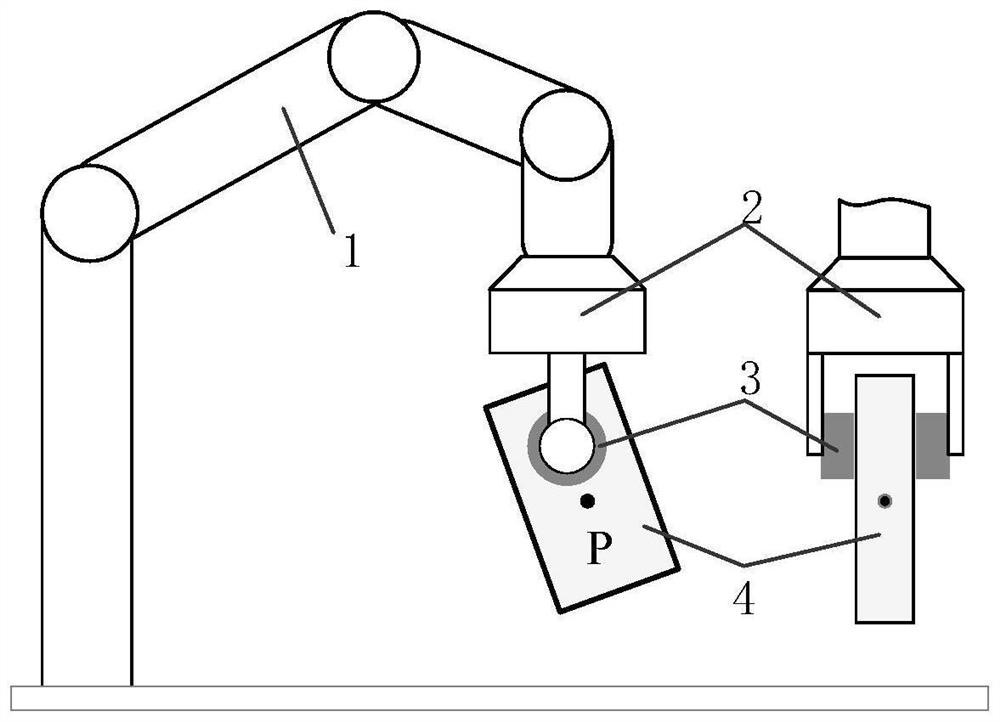

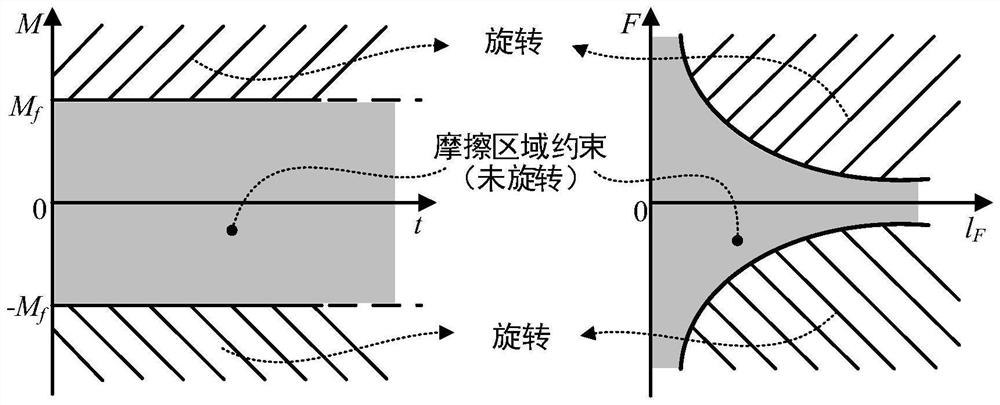

[0028] like figure 1 As shown, the target rotation detection method suitable for the manipulator in-hand operation is suitable for the target grasping and target operation of the robot, especially the rotation detection of the work target after the robot grasps the target. The system involved in the rotation detection of the job target, as shown in the appendix figure 2 As shown, it includes a robot arm 1, a robot hand 2, a force / torque sensor 3, and a work target 4.

[0029] The robotic arm 1 is a multi-axis robotic arm with a common path planning function.

[0030] The manipulator 2 is a two-finger manipulator and can perform online posture adjustment. The manipulator can be installed at the end of the manipulator 1 , and cooperate with the manipulator 1 to grasp the work target 4 .

[0031] The force / torque sensor 3 can be integrated at the fingertip position of the manipulator 2, and has the ability to detect three-dimensional force and three-dimensional moment. Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com