A four-eye wrench

A wrench and wrench rod technology, applied in the field of wrenches, can solve the problems of gap between sleeve and collar, poor connection reliability, inconvenient storage and placement, etc., and achieve the effects of easy storage and placement, good rigidity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

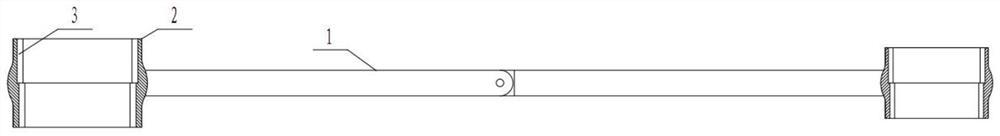

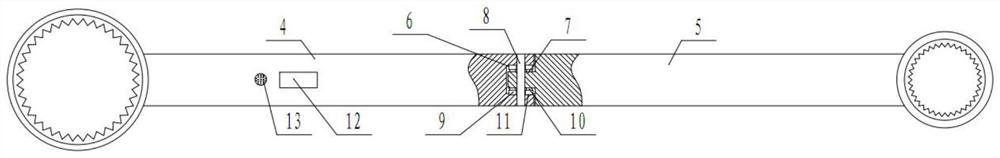

[0017] Embodiment 1: as Figure 1-Figure 3 As shown, a four-eye wrench includes a wrench rod 1 and a wrench head 2. Two wrench heads 2 of different specifications are fixedly connected to both ends of the wrench rod 1. Two ends of the length direction of each wrench head 2 are provided with two wrench heads of different specifications. The quincunx-shaped sleeve 3, the wrench rod 1 is a folding structure and folds towards the length direction of the wrench head 2.

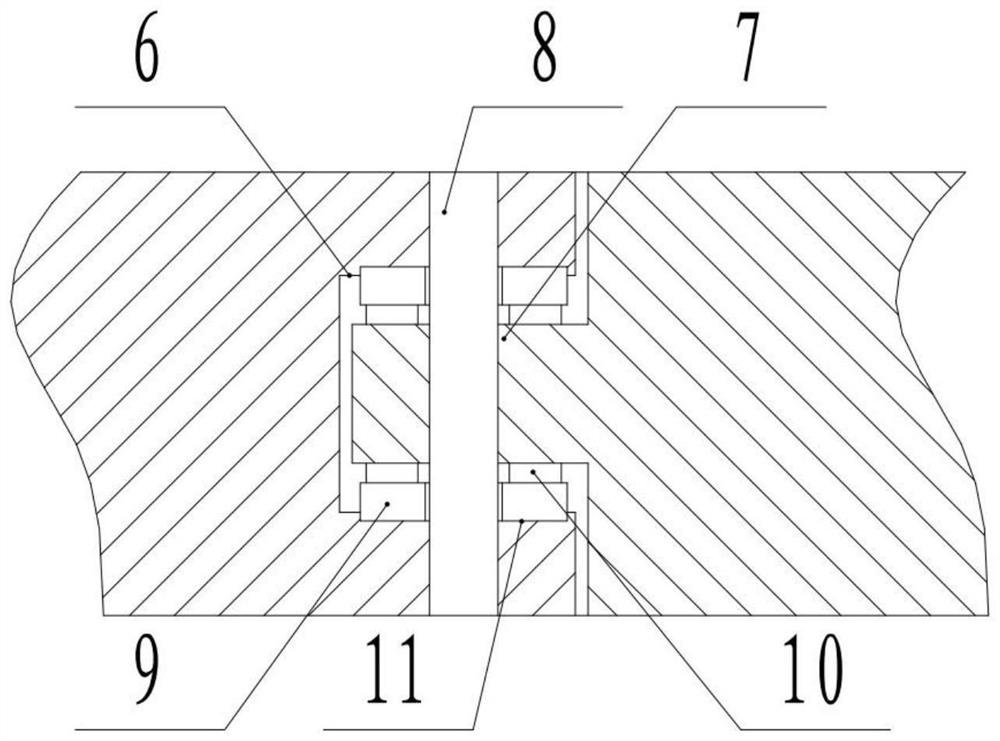

[0018] Preferably, the above wrench rod 1 includes a first segment rod 4 and a second segment rod 5, the folded end of the first segment rod 4 is provided with a U-shaped notch 6, and the folded end of the second segment rod 5 is provided with a convex head 7, The embossed head 7 is embedded in the U-shaped notch 6 and connected by the rotating shaft 8, and the rotating shaft is fixedly connected with the U-shaped notch 6. The double-ear and single-ear folding structure is adopted. The structure is simple, the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com