Galvanic coupling atmospheric corrosion sensor and manufacturing method thereof

A technology of atmospheric corrosion and manufacturing method, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc., can solve the problem that the measurement results cannot be directly fed back to the corrosion of the metal to be measured, the thickness of epoxy resin glue is difficult to control, only As a reference and other issues, to achieve the effect of controllable and good consistency, low cost and high sensitivity

Pending Publication Date: 2020-08-25

北京国网弘泰科技有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under this production process, the thickness of the epoxy resin glue is difficult to control, the consistency is poor and the production cost is high

Moreover, when measuring the corrosion of metals, the object to be tested (such as metal towers, pipes, etc.) cannot be directly used as an anode, and only the metal of the same

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

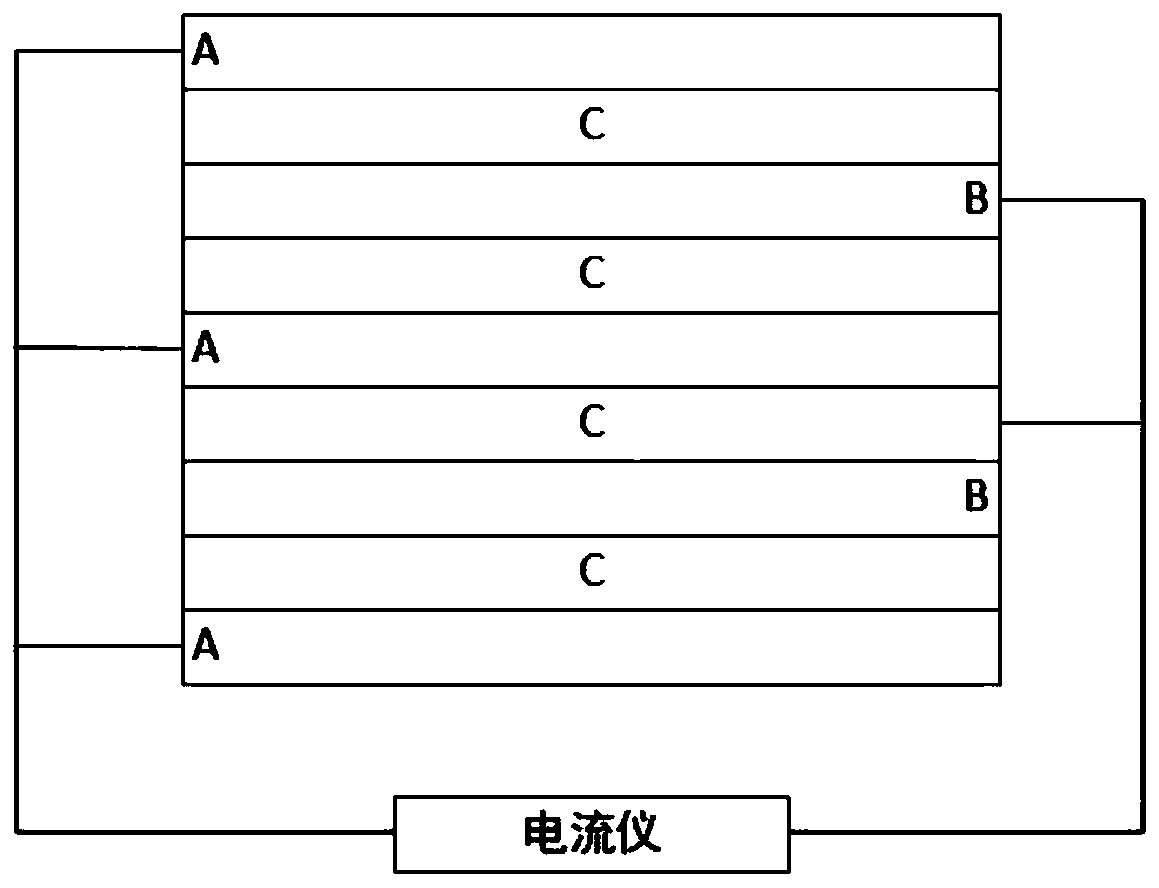

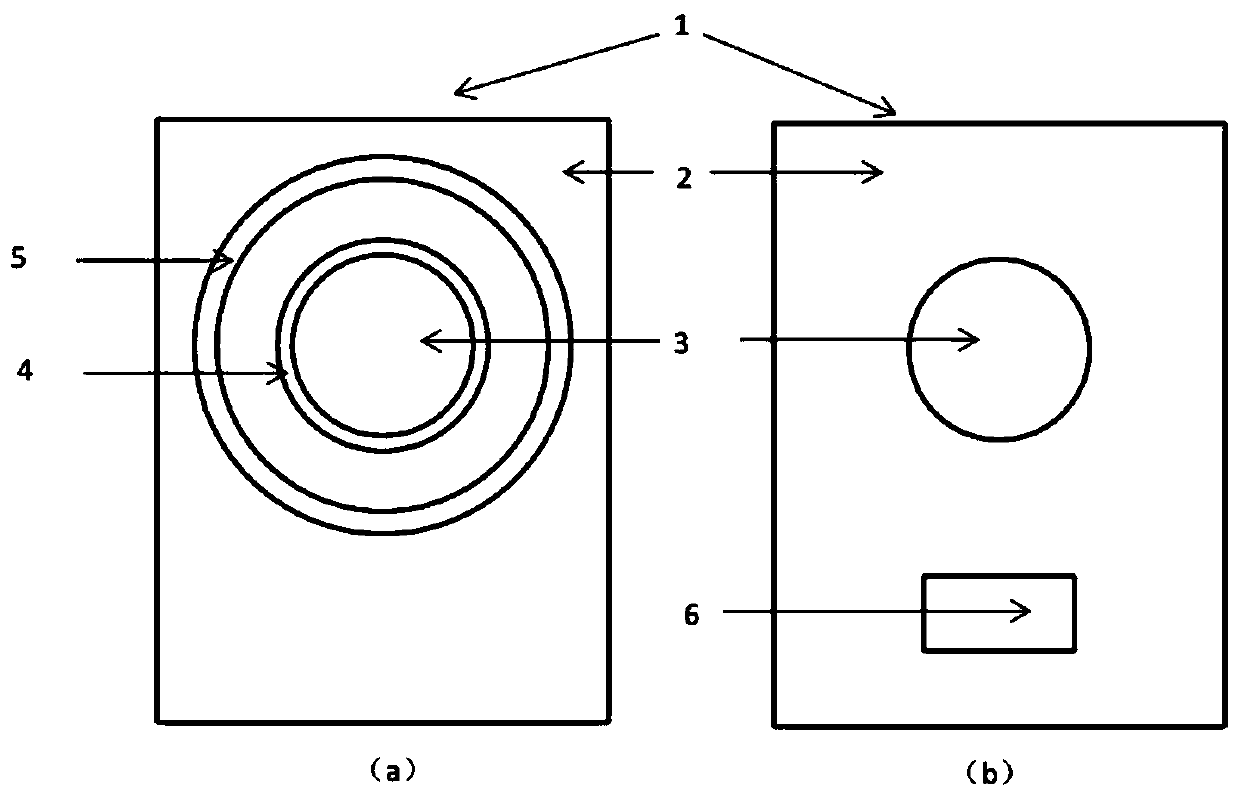

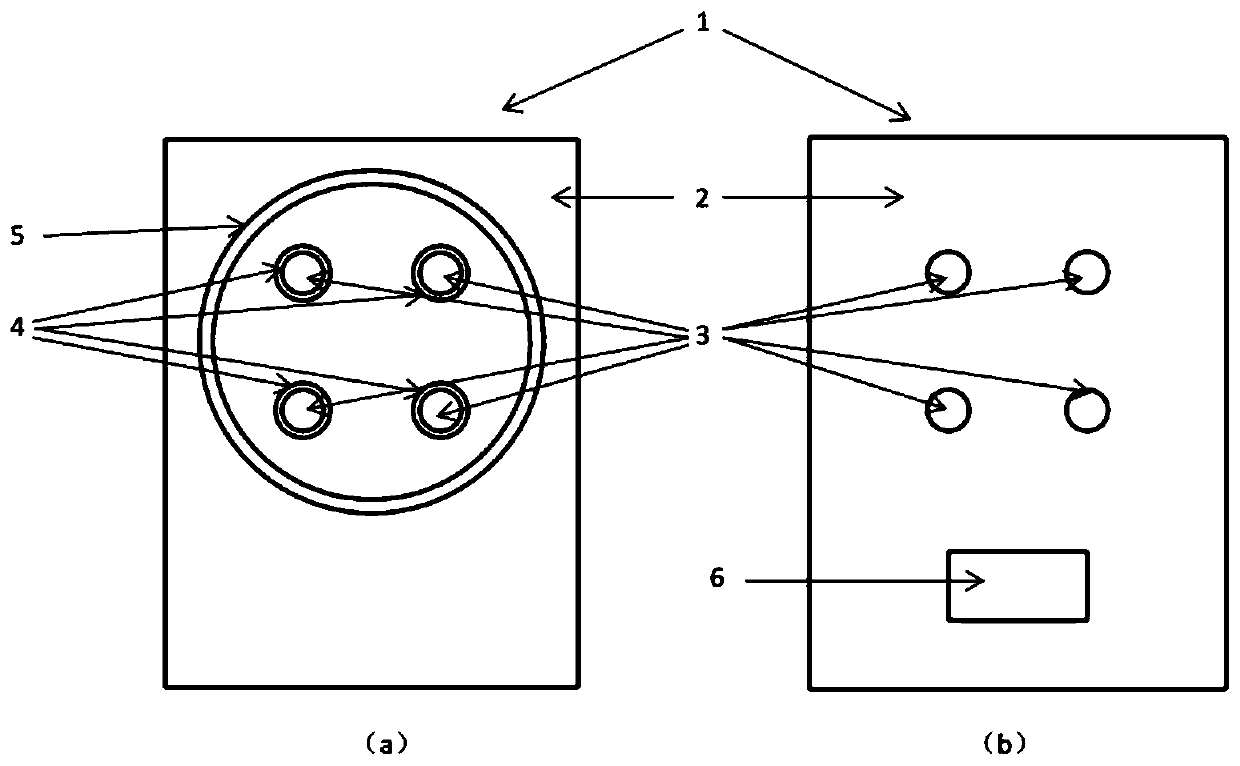

The invention relates to the field of atmospheric corrosion monitoring, and provides a galvanic couple method atmospheric corrosion sensor and a manufacturing method thereof. The sensor comprises a substrate, wherein a through hole is formed in the substrate; a cathode which is arranged on one side of the substrate and clings to the edge of the through hole; a retaining ring, wherein the retainingring and the cathode are arranged on the same side of the substrate, and the retaining ring surrounds the cathode; a tested metal connecting sheet which is arranged on the other side of the substrateand is used for connecting the sensor and the tested metal. The beneficial effects of the sensor are that the sensor is convenient to operate, high in sensitivity, simple in manufacturing method, lowin cost and suitable for industrial large-scale production.

Description

technical field [0001] The invention relates to the field of atmospheric corrosion monitoring, in particular to a galvanic atmospheric corrosion sensor and a manufacturing method thereof. Background technique [0002] Metal corrosion refers to the phenomenon that the state of the metal material is changed by the action of the medium, and it is transformed into a new phase, thereby being damaged. Metal corrosion directly or indirectly causes significant economic losses every year. According to statistics, the amount of metal scrapped due to corrosion every year in the world is equivalent to 1 / 4 to 1 / 3 of the annual output of metal. Therefore, the monitoring of atmospheric corrosion of metals is very important. The traditional metal atmospheric corrosion monitoring method is the exposure method, which exposes the samples made of the metal to be evaluated to the atmospheric environment, and takes them back for weighing at regular intervals. This method needs to establish a g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N17/02

CPCG01N17/02

Inventor 周辉

Owner 北京国网弘泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com