Ampoule bottle tray filling machine and tray filling method thereof

A technology of ampoules and trays, which is applied to conveyors, packaging sterilization, conveyor objects, etc., can solve the problems of easily inverted bottles, unable to achieve misaligned arrangement of bottles in each row, and insufficiently arranged bottle bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

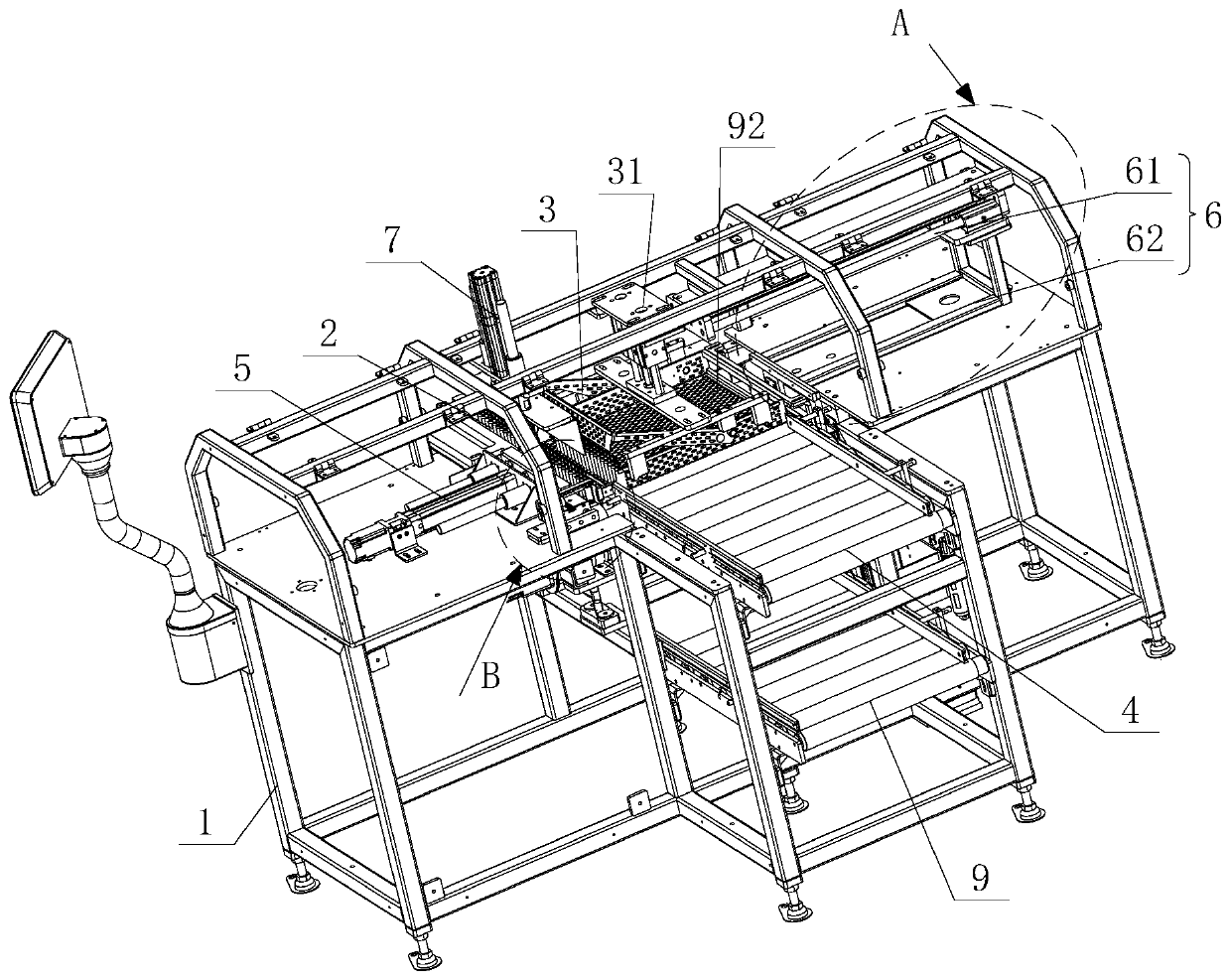

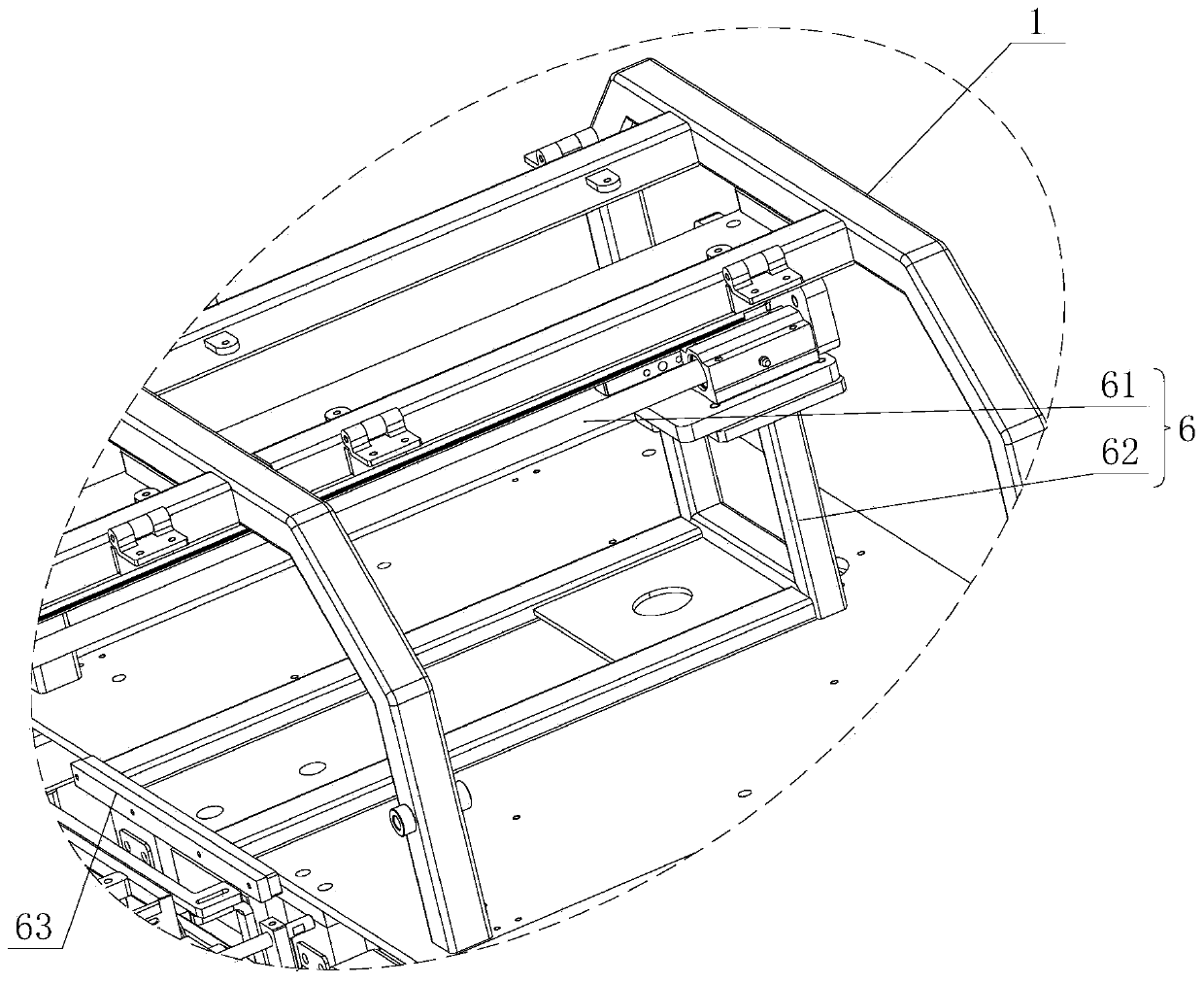

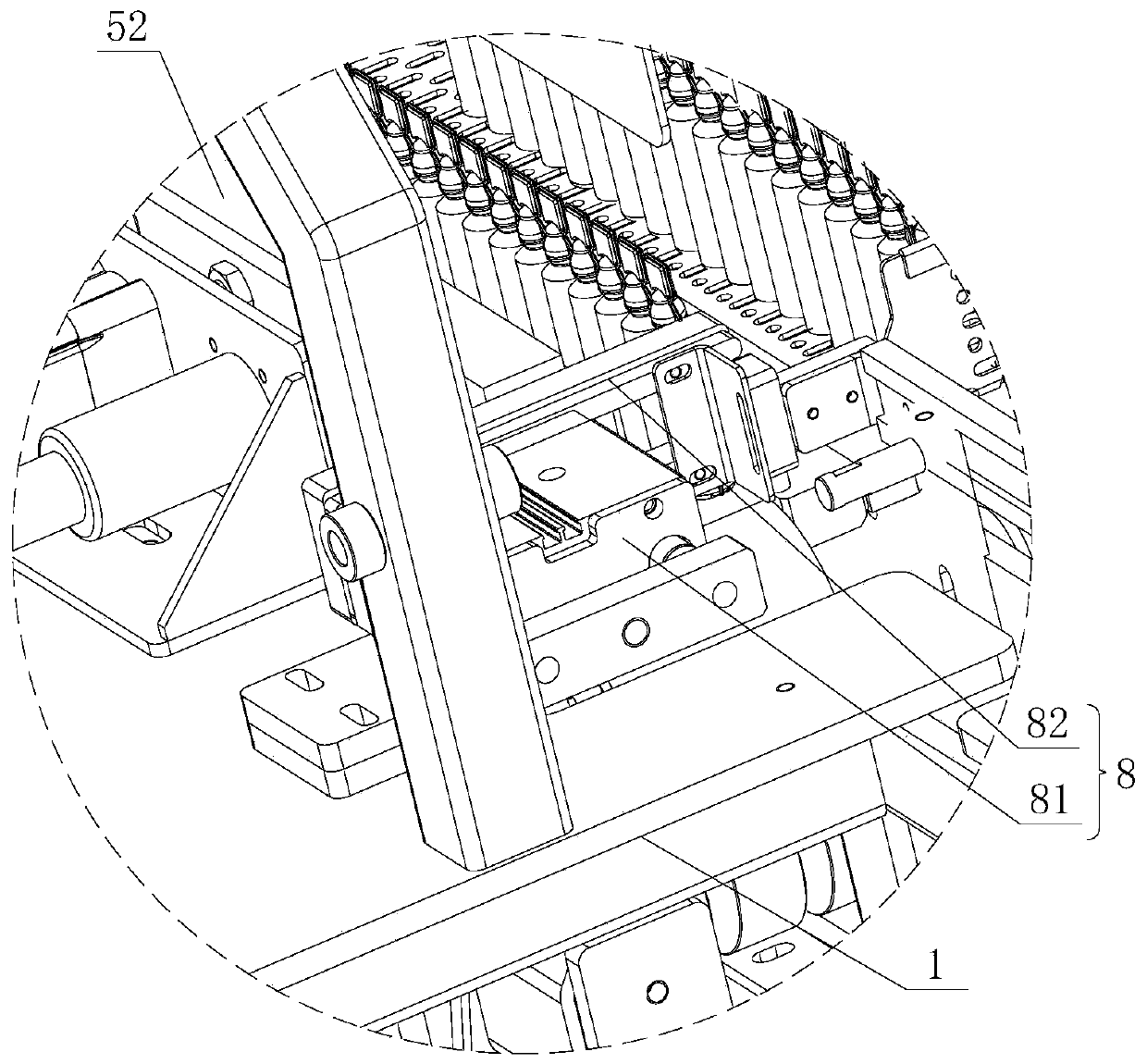

[0039] Figure 1 to Figure 9 Shown is an embodiment of the ampoule bottle filling machine of the present invention, the ampoule bottle filling machine includes a frame 1 and a bottle feeding mechanism 2, a plate loading area 3 and a plate delivery mechanism 4 arranged on the frame 1, the frame 1 is also provided with a bottle pushing mechanism 5 for pushing the bottle body on the bottle feeding mechanism 2 to the loading panel area 3, a bottle pushing mechanism 6 for protecting the bottle when the bottle pushing mechanism 5 pushes the bottle, and a lifting mechanism 6. The bottle feeding and protecting mechanism 7, the bottle feeding mechanism 2 and the bottle pushing and bottle protecting mechanism 6 are respectively located on two opposite sides of the loading panel area 3, the bottle feeding and bottle protecting mechanism 7 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com