Bogie connecting device and process bogie set

A technology of a process bogie and a connecting device, applied in the field of connecting equipment, can solve problems such as the disengagement of the card slot and the separation of the two process bogies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

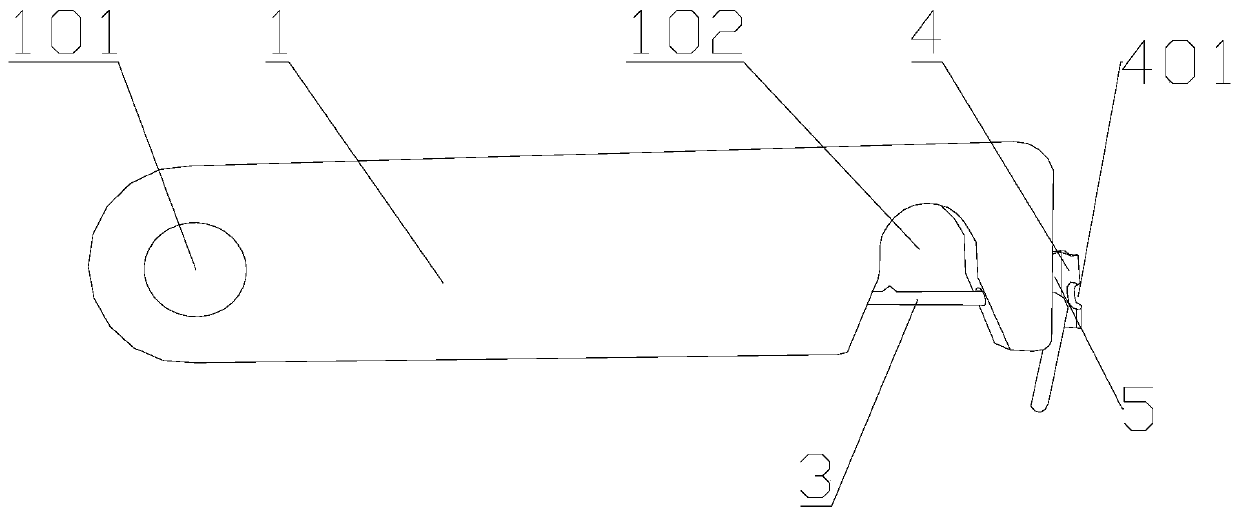

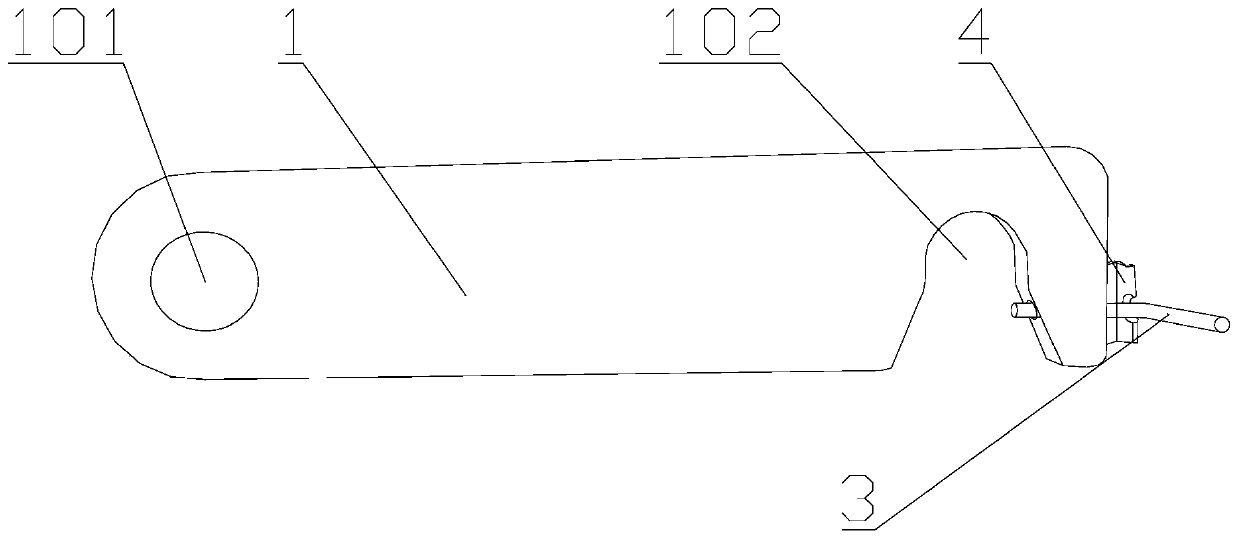

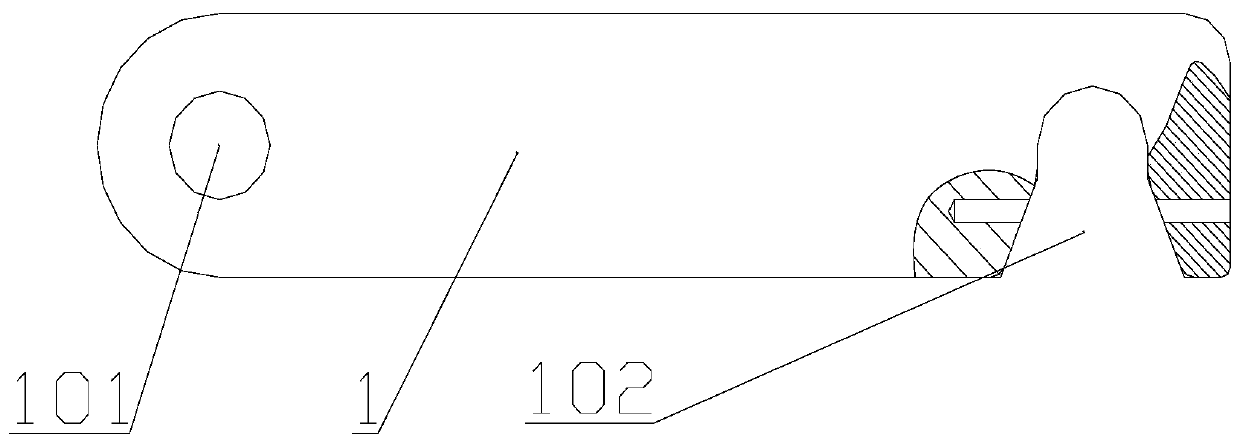

[0044] Such as Figure 1 to Figure 4 As shown, the present invention provides a bogie connecting device, which includes a vertically arranged block body 1, an L-shaped connecting rod 3, an anti-off baffle 4 and a connecting plate 5, wherein: one end of the block body 1 is provided with A through hole 101 that runs through front and rear, a slot 102 is provided on the bottom of the other end of the block-shaped main body 1, and the other end of the block-shaped main body 1 is fixedly connected with one end of the connecting plate 5, and the block-shaped main body The other end of 1 is provided with a through hole arranged along the length direction of the block body 1; the other end of the connecting plate 5 is fixedly connected with one end of the anti-off baffle 4, and the anti-off baffle 4 The other end of the front and rear is provided with a front and rear through groove 401, the groove 401 is connected with the slot 102 through the through hole, and the anti-falling baffl...

Embodiment 2

[0050] The difference from Example 1 is that, as Figure 5 and Figure 6 As shown, a process bogie group is provided, including the bogie connecting device as described in Embodiment 1, the first process bogie 8, the second process bogie 9 and the nut 6, wherein: the first process bogie The frame 8 is fixed with a vertically arranged screw rod 801, and the screw rod 801 is movably socketed with the through hole 101 on the block body 1 and then threadedly connected with the nut 6; the second process bogie 9 is fixed with a vertically arranged fixing column 901 , the fixing column 901 is engaged with the slot 102 and is located in the closed space formed by the slot 102 and the L-shaped connecting rod 3 .

[0051] Optionally, the side wall of the L-shaped connecting rod 3 abuts against the side wall of the fixing column 901 .

[0052] Optionally, a washer 2 is further included, and the washer 2 is socketed on the bolt 801 and located between the block body 1 and the nut 6 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com