Vein type perfusion adapter tube and perfusion method

A leaf vein and pipeline technology, applied in the field of leaf vein type perfusion connection and perfusion, can solve the problems of difficult distance control, air sac, and long perfusion time, and achieve the effect of reducing operation difficulty, reducing resin consumption, and reducing perfusion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

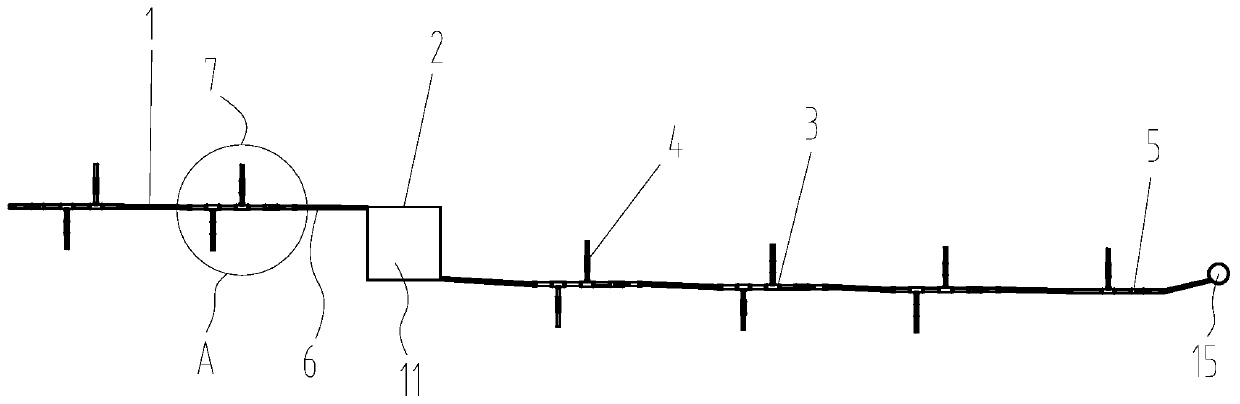

[0028] Embodiment 1, the present invention provides a vein type perfusion joint, such as figure 2 As shown, it includes the injection port 1, the buffer channel 2, the main channel 3, the secondary channel 4 and the plastic outlet 5 in sequence. The buffer channel 2 is between the injection port 1 and the main channel 3, and the secondary channel 4 is a leaf vein. Distributed and connected to the main flow channel 3, the end of the main flow channel 3 is provided with a glue outlet 5, and the glue injection port 1, the buffer channel 2, the main flow channel 3, the secondary flow channel 4 and the glue outlet 5 are all passed through a steel wire spiral tube 6 is connected, and the end of the glue outlet 5 is connected to the integrated gluer 15.

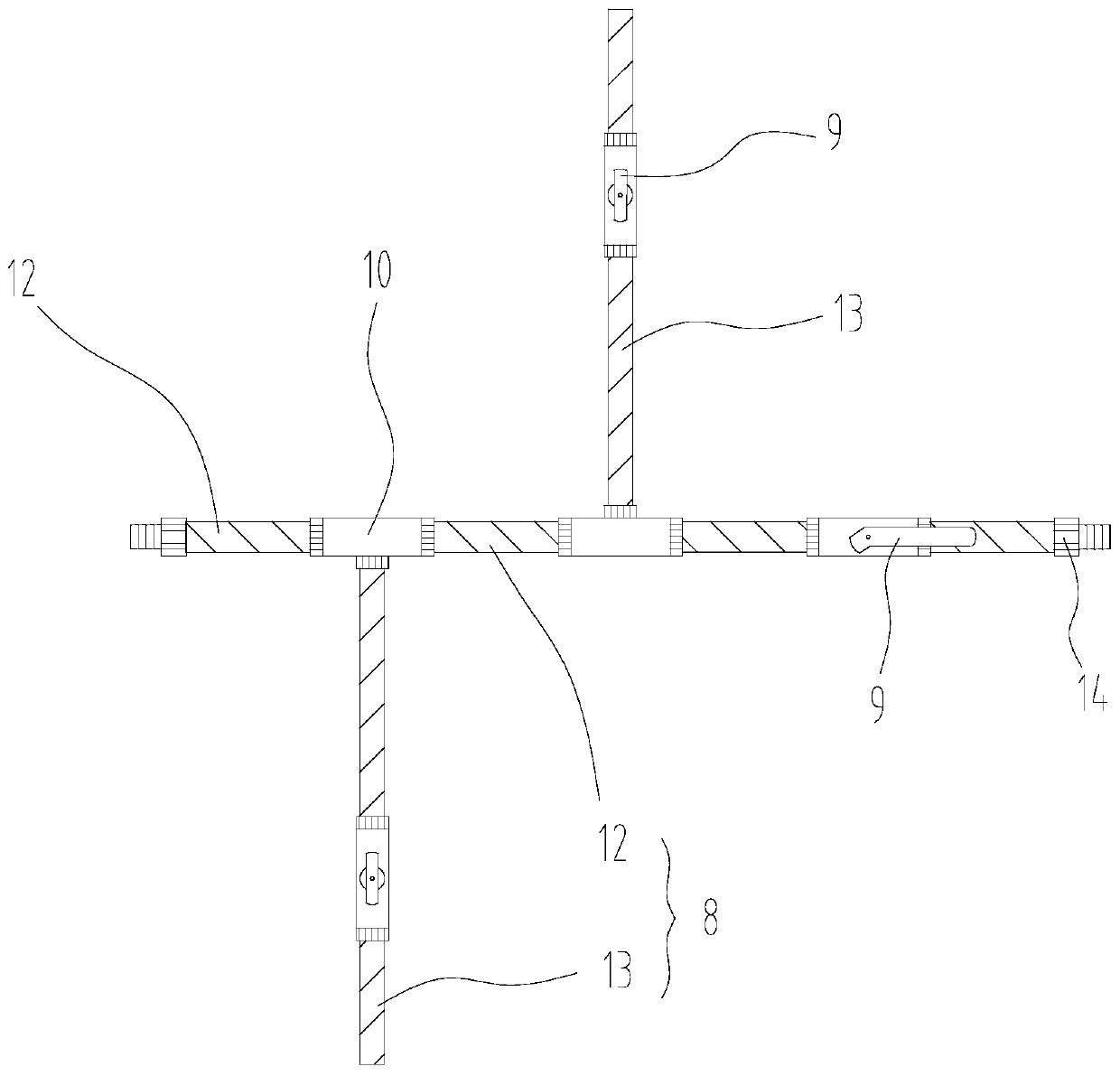

[0029] The glue injection port 1 includes a first pipeline 7, the number of the first pipeline 7 is more than two, and a plurality of first pipelines 7 are connected sequentially through the steel wire spiral tube 6, as image 3 A...

Embodiment 2

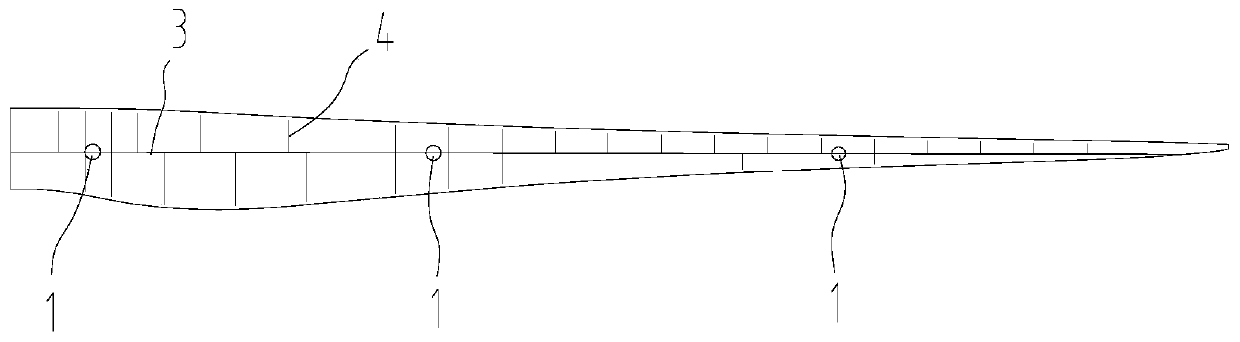

[0043] In the second embodiment, the main channel 3 can be appropriately increased according to the demand. In this embodiment, the number of the main channel 3 is more than two, and it is connected with the steel wire spiral tube 6 through the green head 16, such as figure 1 As shown, each main channel 3 is provided with a glue injection port 1 . When the perfusion product has a large area corner and the cloth layer is thick, it is easy to produce a perfusion partition, and the main channel 3 can be appropriately added in this area to supply glue, and the secondary channel 4 is adjusted according to the number of the main channel 3, and the rest is the same as the embodiment one.

Embodiment 3

[0044] Embodiment 3, the vein-type joint is not limited to the production of wind power blade glue filling, but also can be used in the production of other pouring products, such as blade prefabricated parts, root tiles, webs, etc., and the rest are the same as Embodiments 1 and 2.

[0045] The PPR pipe (DN25) 12 and the PPR pipe (DN20) 13 are PPR pipes 8 with outer diameters of 25 and 20 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com