Floor embossing device for road construction

A road construction and floor embossing technology, which is applied in the field of floor embossing devices for road construction, can solve problems such as high labor intensity, reduced embossing efficiency, and poor embossing effect, so as to reduce labor intensity and improve embossing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

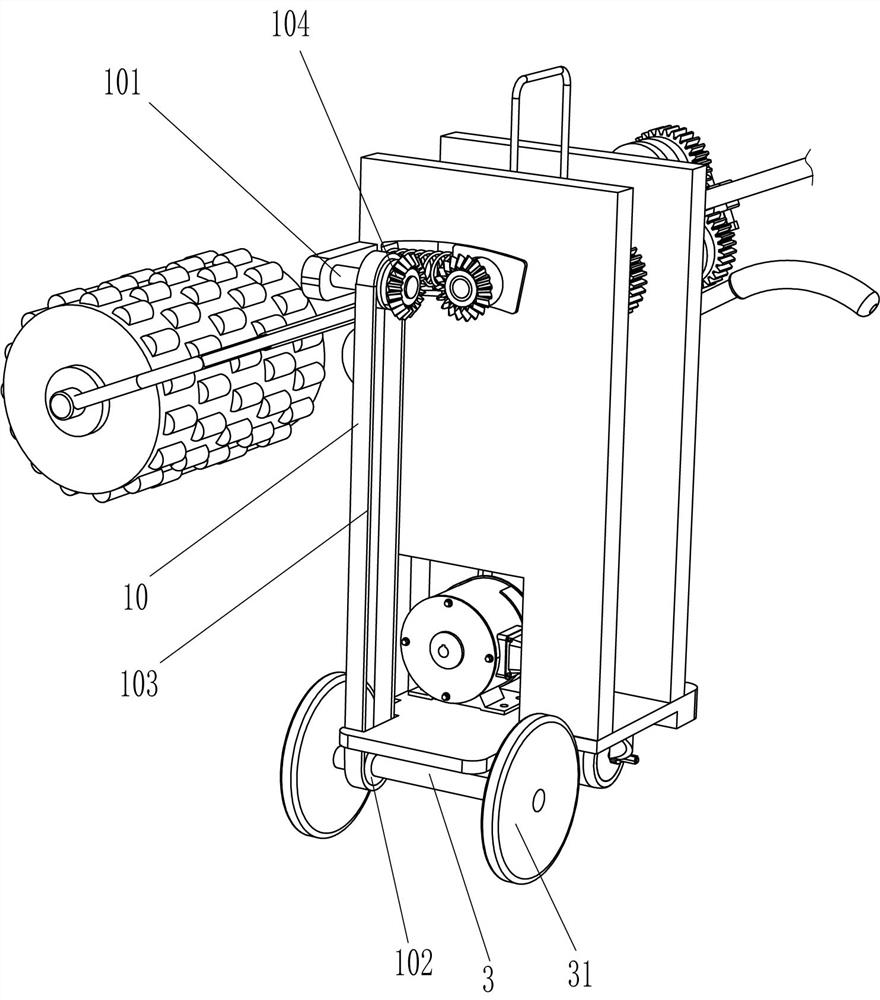

[0027] A floor embossing device for road construction, such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, it includes base 1, universal wheel 2, connecting shaft 3, traveling wheel 31, support plate 4, driving mechanism 5, moving mechanism 6, moving rod 7 and pressure roller 8, and the bottom front side of base 1 is connected with ten thousand To the wheel 2, the bottom rear side of the base 1 is rotatably connected to the connecting shaft 3, the left and right ends of the connecting shaft 3 are connected to the walking wheels 31, the front and rear sides of the top of the base 1 are connected to the support plate 4, and the two support plates A driving mechanism 5 is installed on the top of the base 1 between 4, and a moving mechanism 6 is installed on the left side of the upper part of the front support plate 4. The driving mechanism 5 is connected to the moving mechanism 6, and a moving rod 7 is placed on the moving part of the moving mechanism 6. , the rig...

Embodiment 2

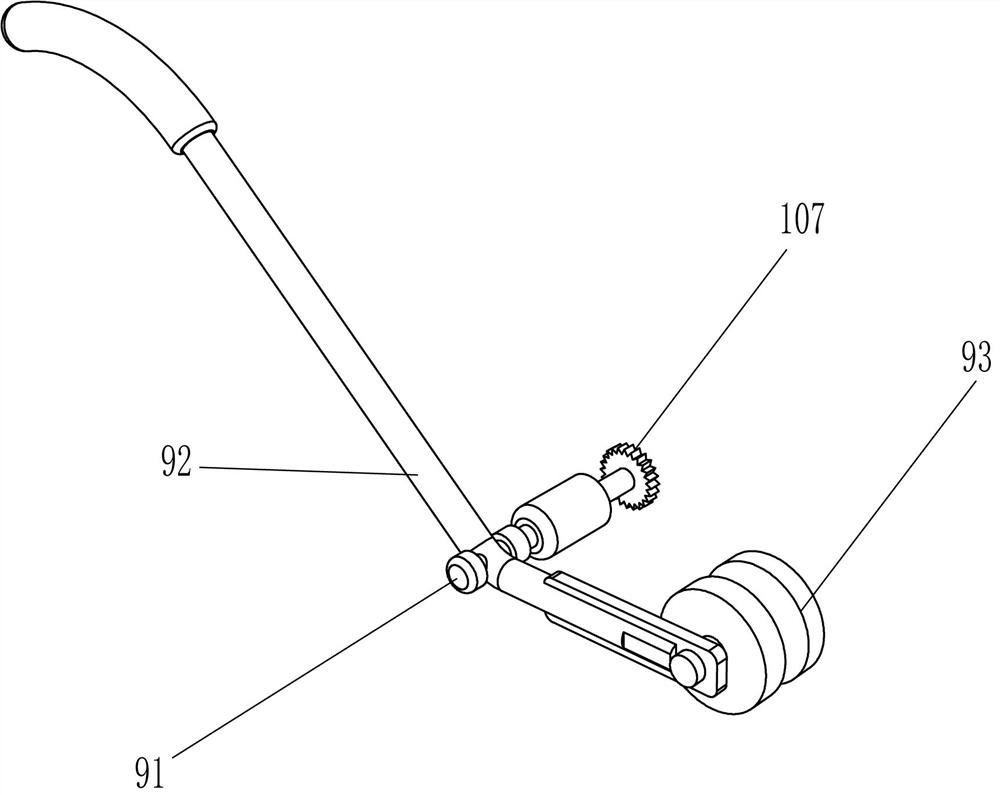

[0032] On the basis of Example 1, such as Figure 1-2 As shown, it also includes a tilting device 9, the tilting device 9 includes a fourth rotating shaft 91, a swing lever 92 and a support wheel 93, and the lower right part of the front side support plate 4 is rotatably connected with a fourth rotating shaft 91, and the fourth rotating shaft 91 runs through the front side support plate 4, and the front part of the fourth rotating shaft 91 is connected with a swing bar 92, and the rear side right part of the swing bar 92 is fixedly connected with a support wheel 93, and the support wheel 93 contacts with the moving bar 7.

[0033] Manually press the left side of the swing lever 92 downward, the right side of the swing lever 92 swings upwards accordingly, the fourth rotating shaft 91 rotates counterclockwise thereupon, the right side of the swing lever 92 swings upwards and pushes the moving lever 7 to move upwards, thereby enabling Lift the pressure roller 8. When the moving ...

Embodiment 3

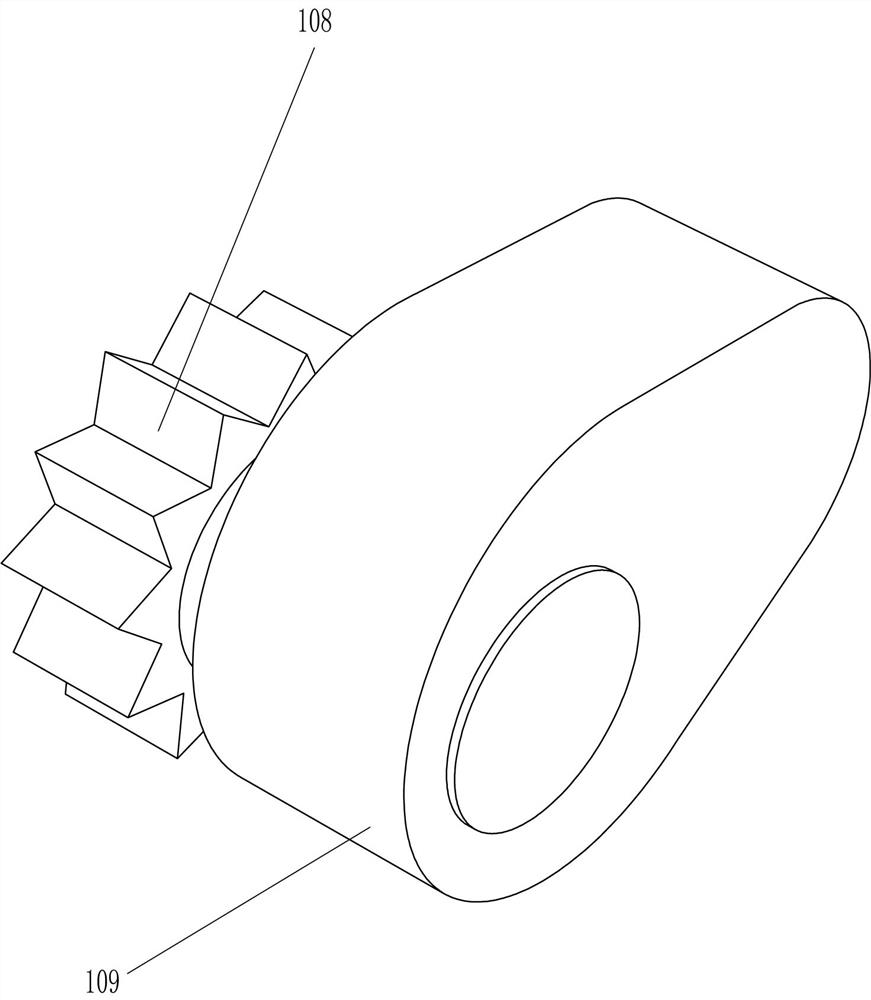

[0035] On the basis of Example 2, such as Figure 4-7 As shown, a linkage assembly 10 is also included, and the linkage assembly 10 includes a fifth rotating shaft 101, a second pulley 102, a second flat belt 103, a first bevel gear 104, a second bevel gear 105, an L-shaped rod 106, a large gear 107, pinion 108, cam 109, the rear side right side of rear side supporting plate 4 is connected with the fifth rotating shaft 101 in a rotary type, the fifth rotating shaft 101 and the connecting shaft 3 are all connected with the second pulley 102, two second pulleys The second flat belt 103 is connected between 102, the left end of the fifth rotating shaft 101 is connected with the first bevel gear 104, the rear end of the first rotating shaft 55 is connected with the second bevel gear 105, the second bevel gear 105 and the first bevel gear 104 meshing, the middle part of the right side of the connecting plate 52 is connected with an L-shaped bar 106, the rear end of the fourth rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com