Multifunctional integrated aviation assembly hole making system and its application method

A multi-functional, motion control system technology that is used in manufacturing tools, measuring devices, boring/drilling, etc., to solve problems such as unfavorable hole-making coverage, increased load and lifting of hole-making machine tools or robots, and improved detection. Accuracy and degree of automation, avoidance of transfer tasks, and the effect of a high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The drawings illustrate embodiments of the invention, and it is to be understood that the disclosed embodiments are merely exemplary of the invention, which may be embodied in various forms and therefore, specific details disclosed herein are not to be interpreted as limiting , but only as a basis for the claims and as a representative basis for teaching one of ordinary skill in the art to variously employ the invention.

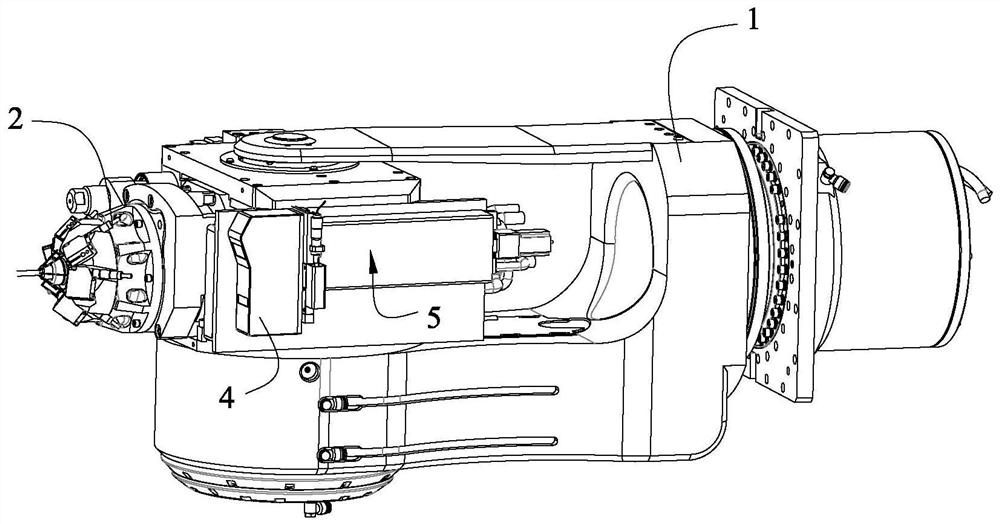

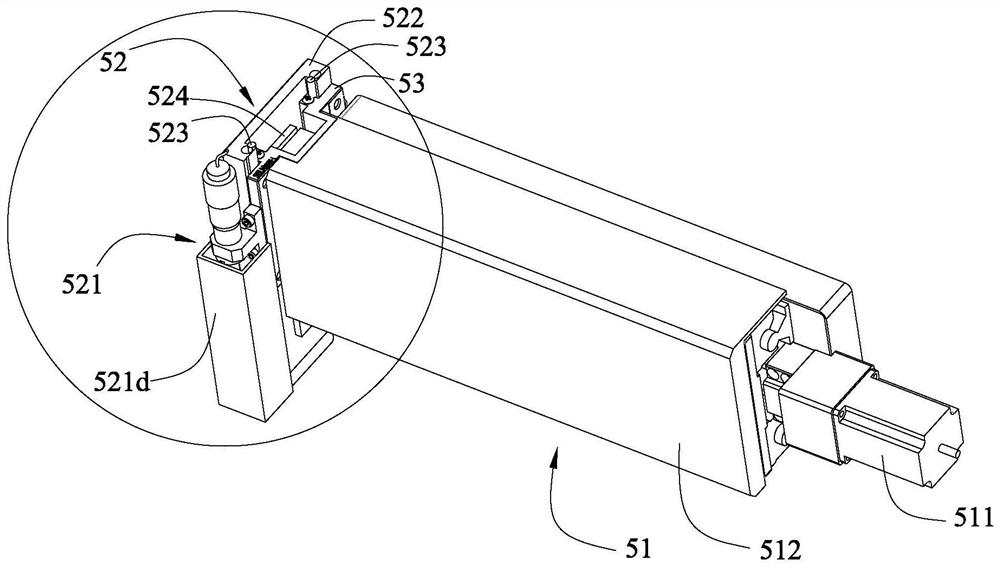

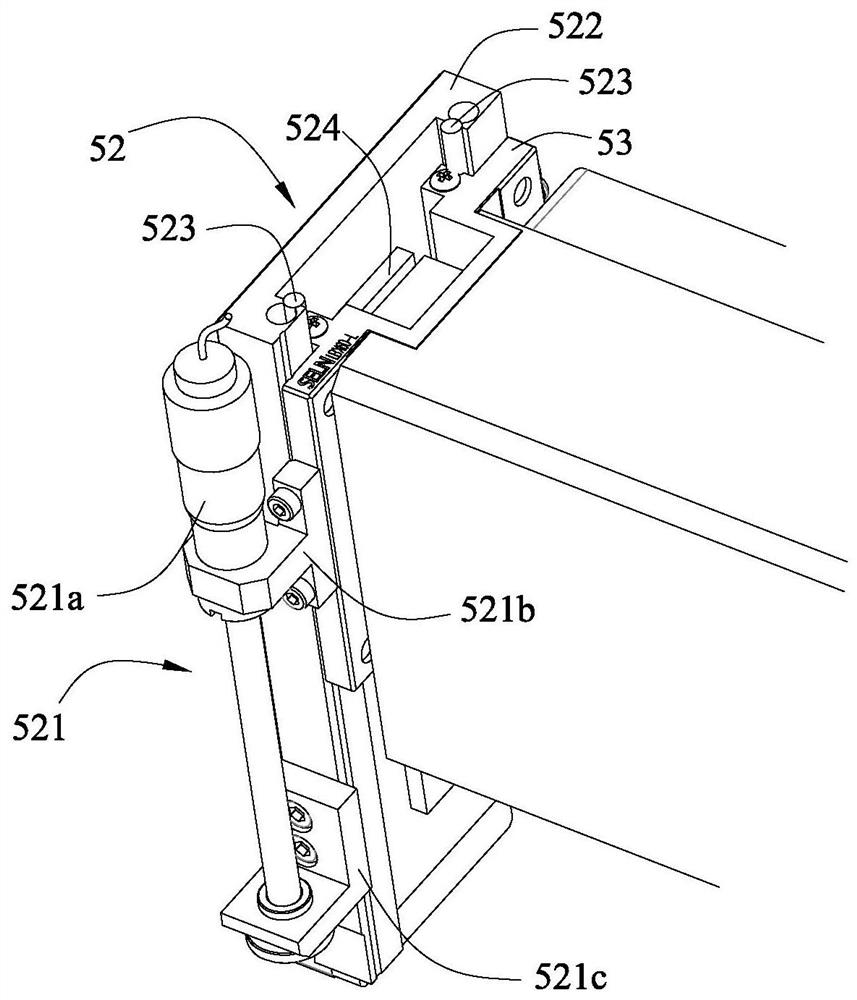

[0041] like Figure 1 to Figure 5 As shown, the multi-functional integrated aviation assembly hole-making system consists of a multi-axis numerical control motion mechanism 1, a hole-making device 2, a multi-axis numerical control motion control system 3, and a line laser scanning sensor 4, a scanning motion mechanism 5, and a scanning motion mechanism control system. 6. Image processing workstation 7 is composed.

[0042] Wherein, the multi-axis numerical control movement mechanism 1 is connected with the hole-making device 2 to drive the hole-makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com