A Salvage Method Based on Underwater Welding

A technology for underwater welding and welding equipment, which is applied in ship salvage, welding equipment, manufacturing tools, etc., can solve the problems of low welding seam quality, poor reliability, unsuitable welding of underwater stress components, etc., so as to reduce salvage costs. , Wide range of applications, the effect of shortening the salvage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. detailed description of the .

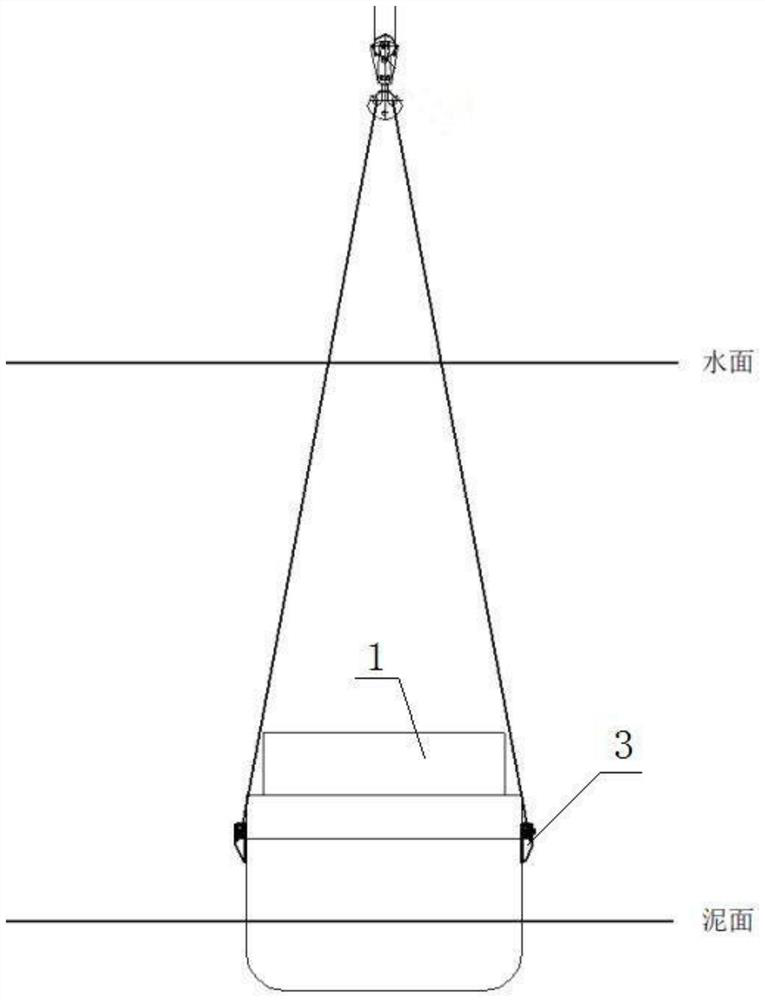

[0033] Such as Figure 1-4 Shown, this salvage method comprises the following steps:

[0034] (1) Explore the situation of the sunken ship 1, and clean up the surrounding obstacles that hinder the salvage of the sunken ship 1;

[0035] (2) ROV or diving survey the structure of the pre-welded position of the hoisting eye plate on the sunken ship, and conduct analysis and evaluation to determine the welding position;

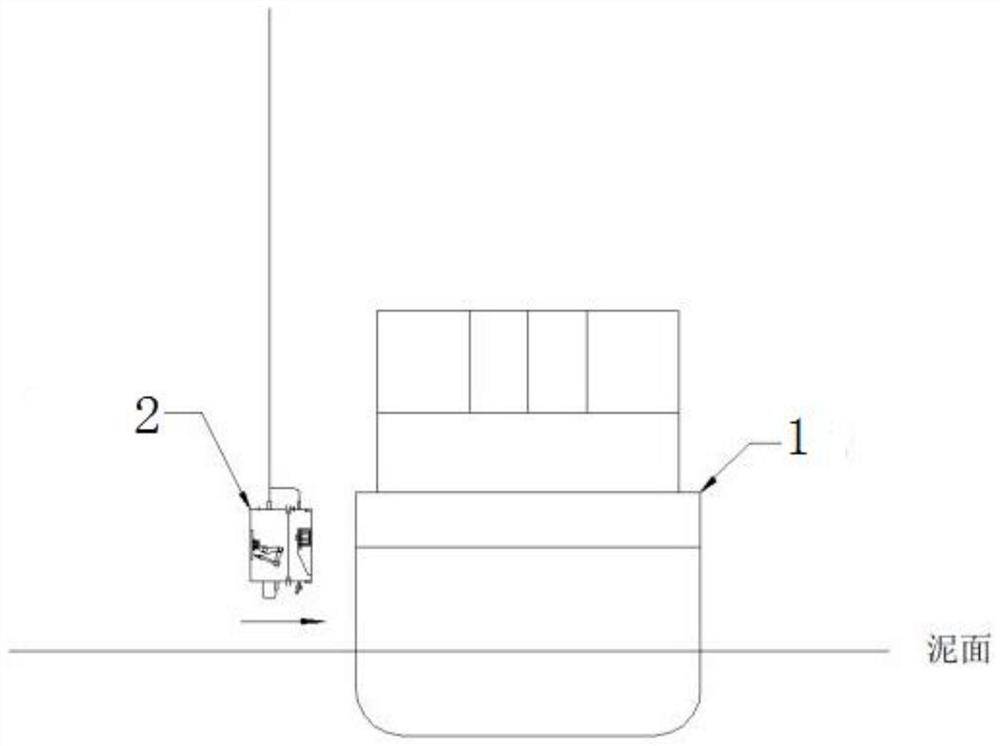

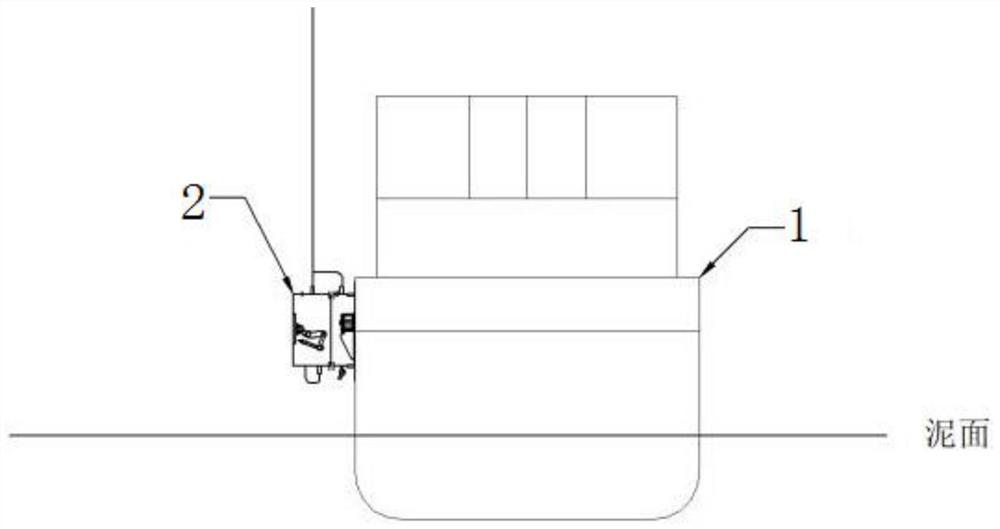

[0036] (3) if figure 1 As shown, arrange the eye plate to be welded on the underwater dry welding equipment, lower the dry welding equipment 2, weld the eye plate 3 on the pre-designed position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com