Uniform force focusing mechanism driven by inclined guide rail

A technology of tilting guide rails and focusing, which is applied in installation, optics, instruments, etc., can solve the problems that the support rigidity is not easy to increase, and achieve the effects of good power transmission effect, improved practicability, and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

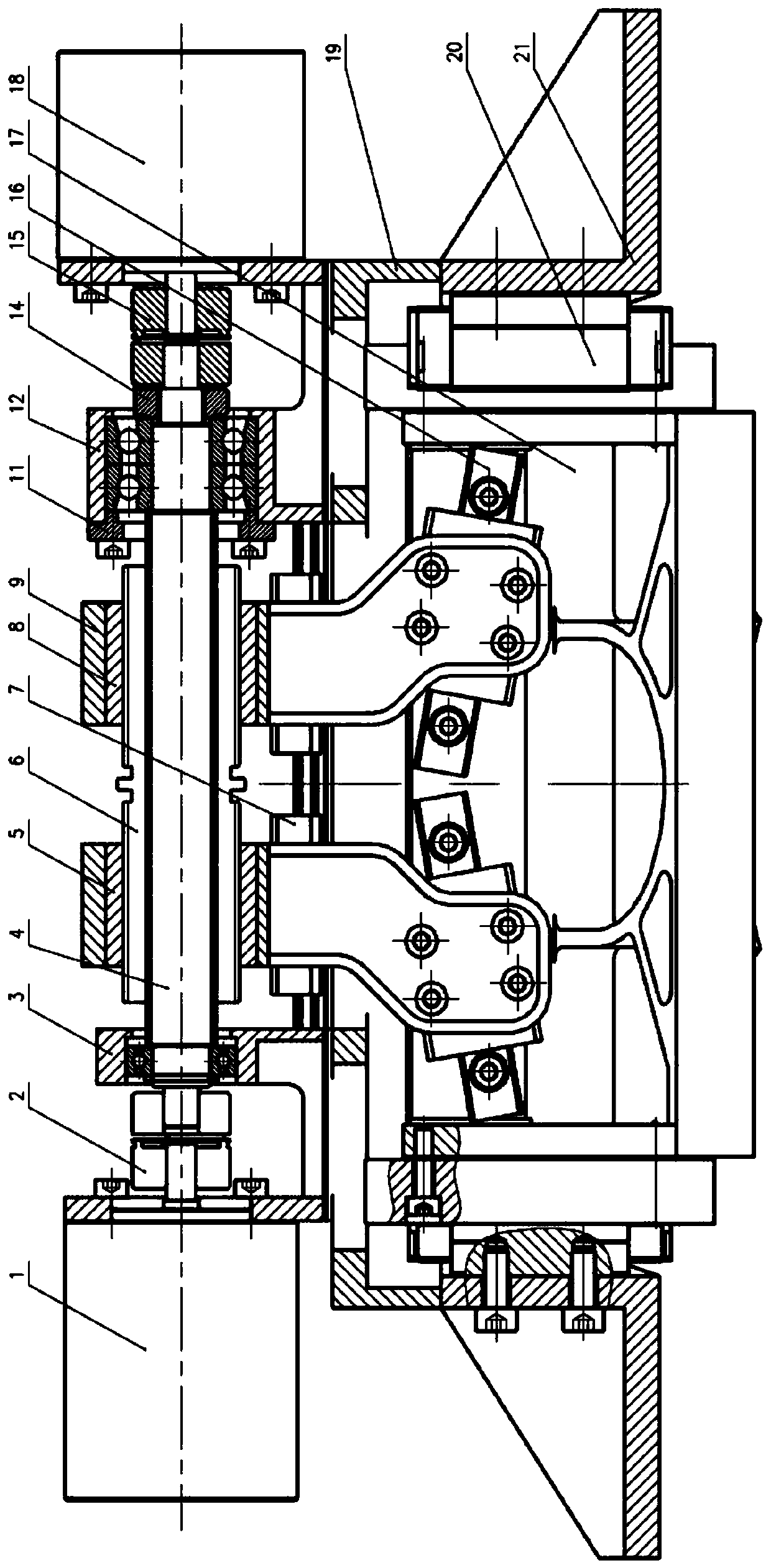

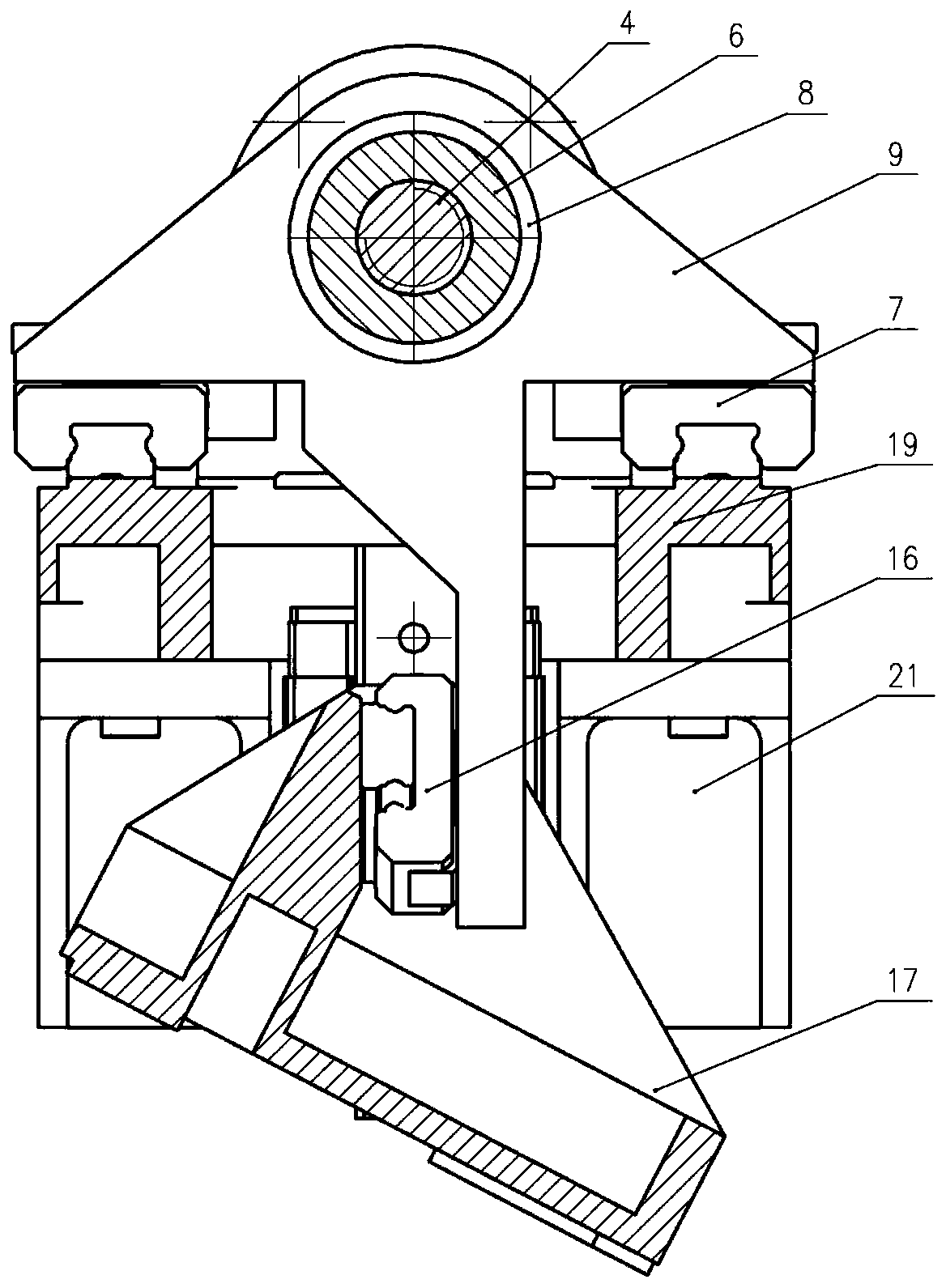

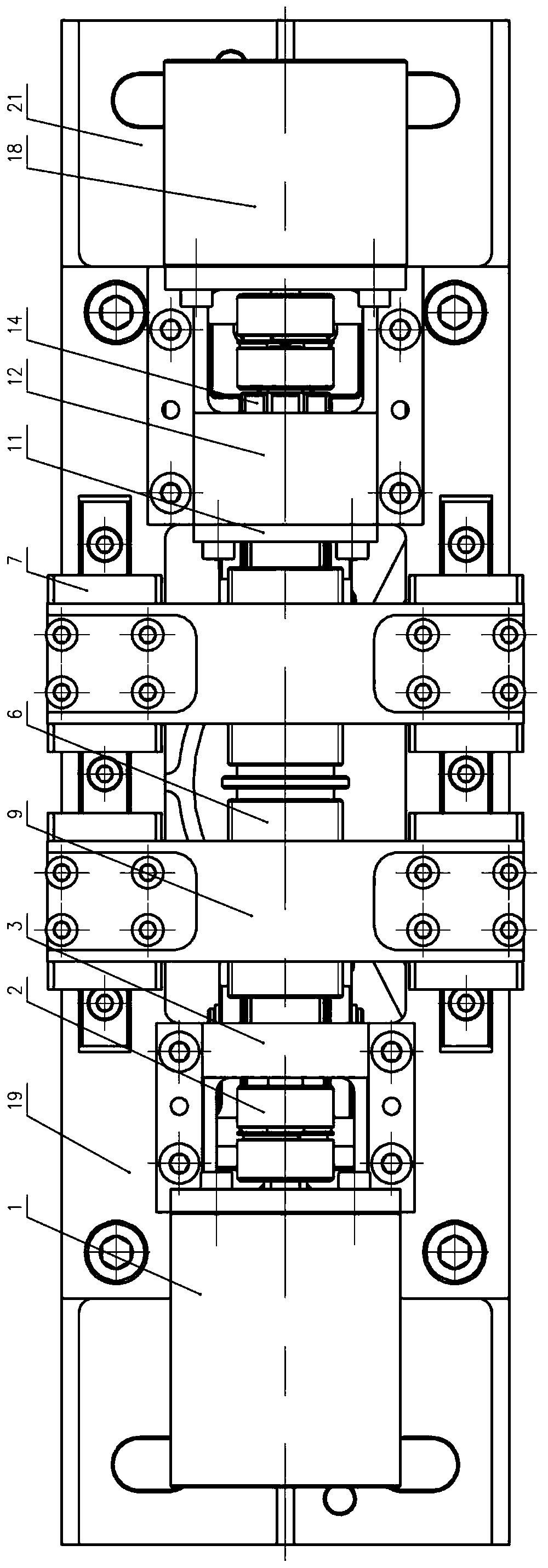

[0055] see Figure 1 ~ Figure 3 shown;

[0056] A uniform focusing mechanism driven by an inclined guide rail according to the present invention, the mechanism mainly includes:

[0057] Focusing mounting base 17, the focusing mounting base 17 is equipped with optical elements;

[0058] The supports 21 that are slidably connected to the two sides of the focusing mount 17 through the vertical linear guide rail 20; and

[0059] Assemble and fix the base 19 on the upper end of the support 21;

[0060] A horizontal focusing assembly is installed on the top of the base 19;

[0061] The focusing mounting base 17 is transmission-connected with the horizontal focusing assembly through a symmetrically arranged wedge-angle slider mechanism;

[0062] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com