Elastic pressing type hot-line work insulating lock rod

A live operation, elastic pressing technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficult adjustment of the length of the insulating lock rod, hidden dangers of accident safety, complicated use, etc., so as to reduce physical energy consumption, lower the use threshold, and open and close freely. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

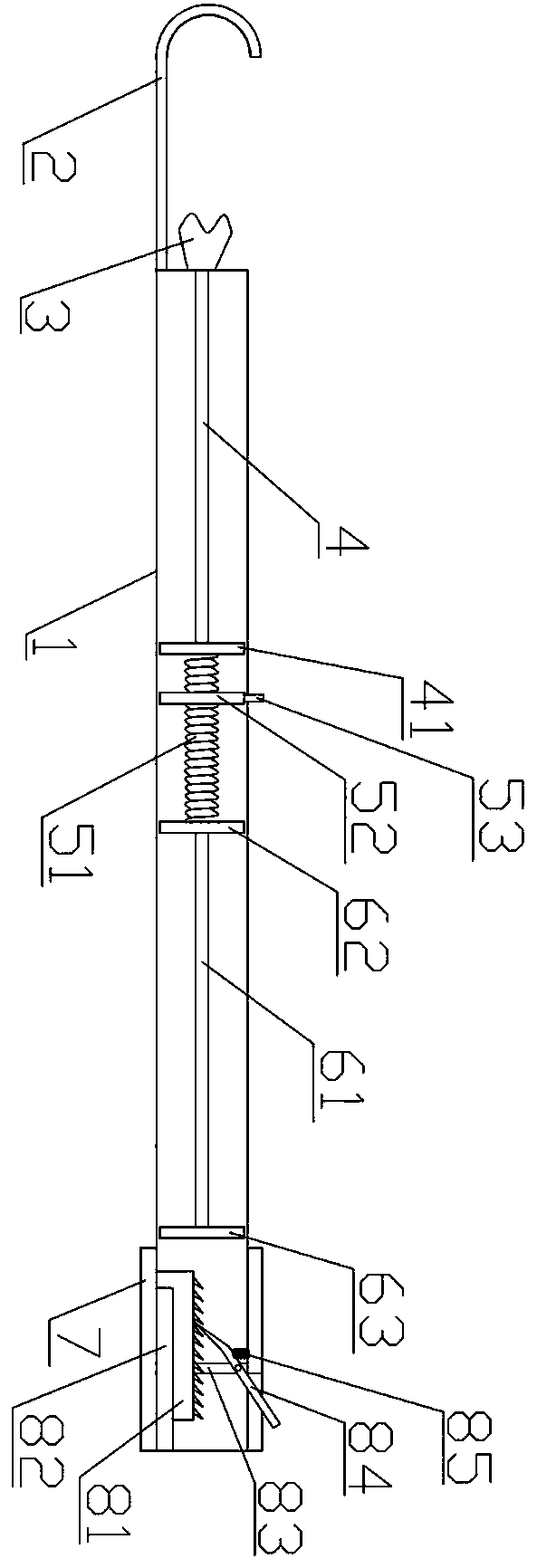

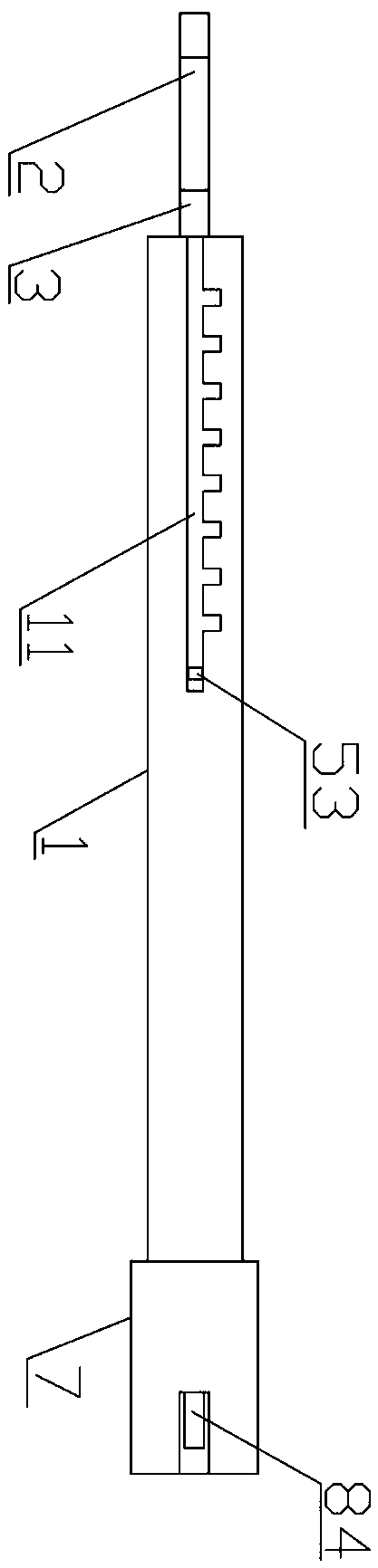

[0020] like Figure 1-2 As shown, a snap-press insulating locking rod for live work includes a hollow cylindrical outer insulating rod 1, a fixed locking hook 2 arranged at one end of the outer insulating rod 1, a clamping mechanism and a locking mechanism arranged in the outer insulating rod 1. Mechanism; the outer insulating rod 1 is provided with an opening at the end far away from the fixed locking hook 2, and the end of the outer insulating rod 1 close to the fixed locking hook is provided with a through hole;

[0021] The clamping mechanism includes a first support rod 4, a second support rod 61 and a Y-shaped movable lock head 3. The movable lock head 3 is arranged near one end of the fixed lock hook 2, and one end of the first support rod 4 stretches out from the through hole and The movable lock head 3 is fixedly connected, and the first support rod 4 is provided with a first stop 41 near one end of the second support rod 61, and the second support rod 61 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com