Gas stove and control method thereof

A gas stove and gas technology, applied in the field of kitchen utensils, can solve the problems such as the inability to ignite the outer ring fire hole alone, the inability to ignite the outer ring fire hole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

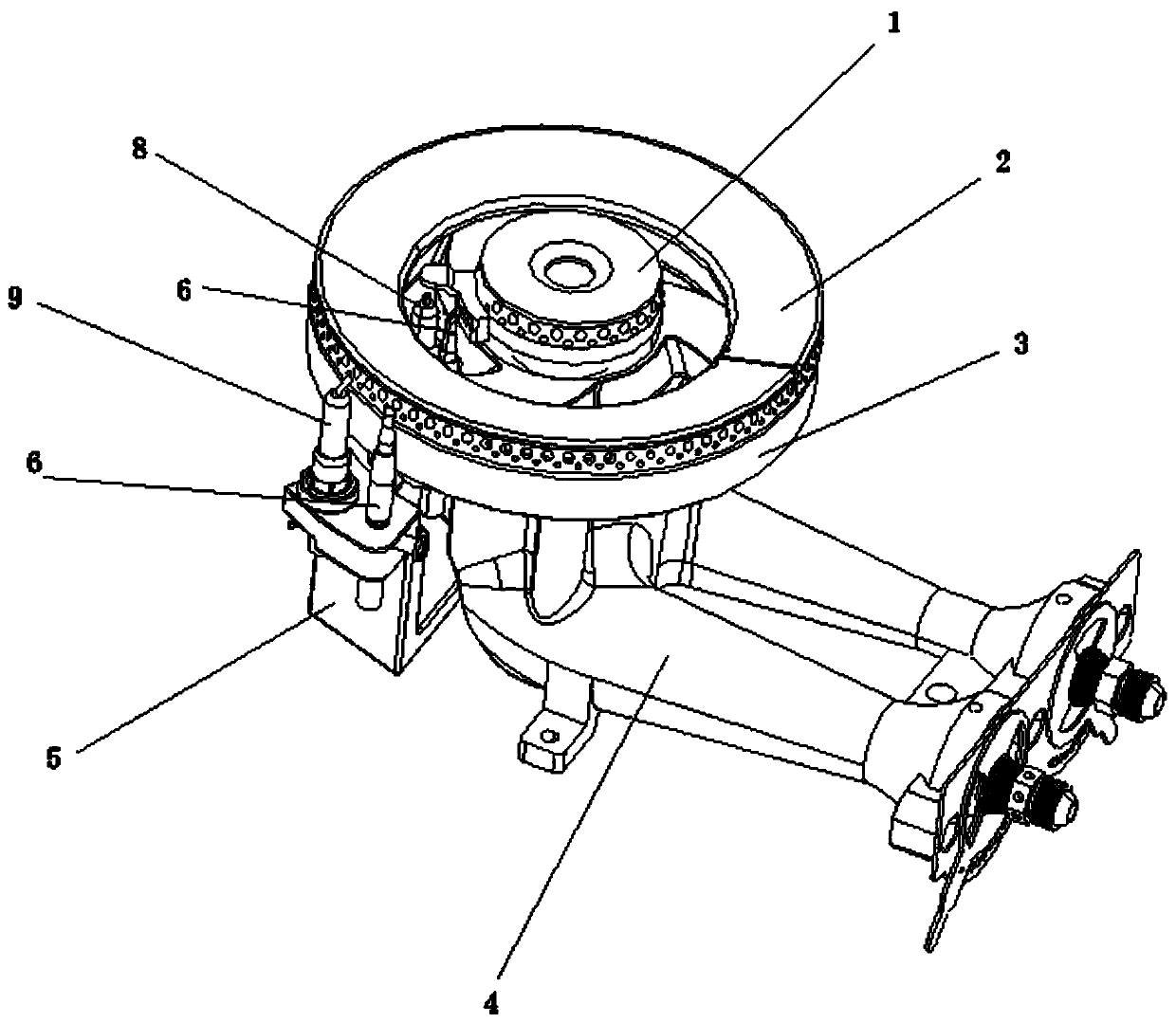

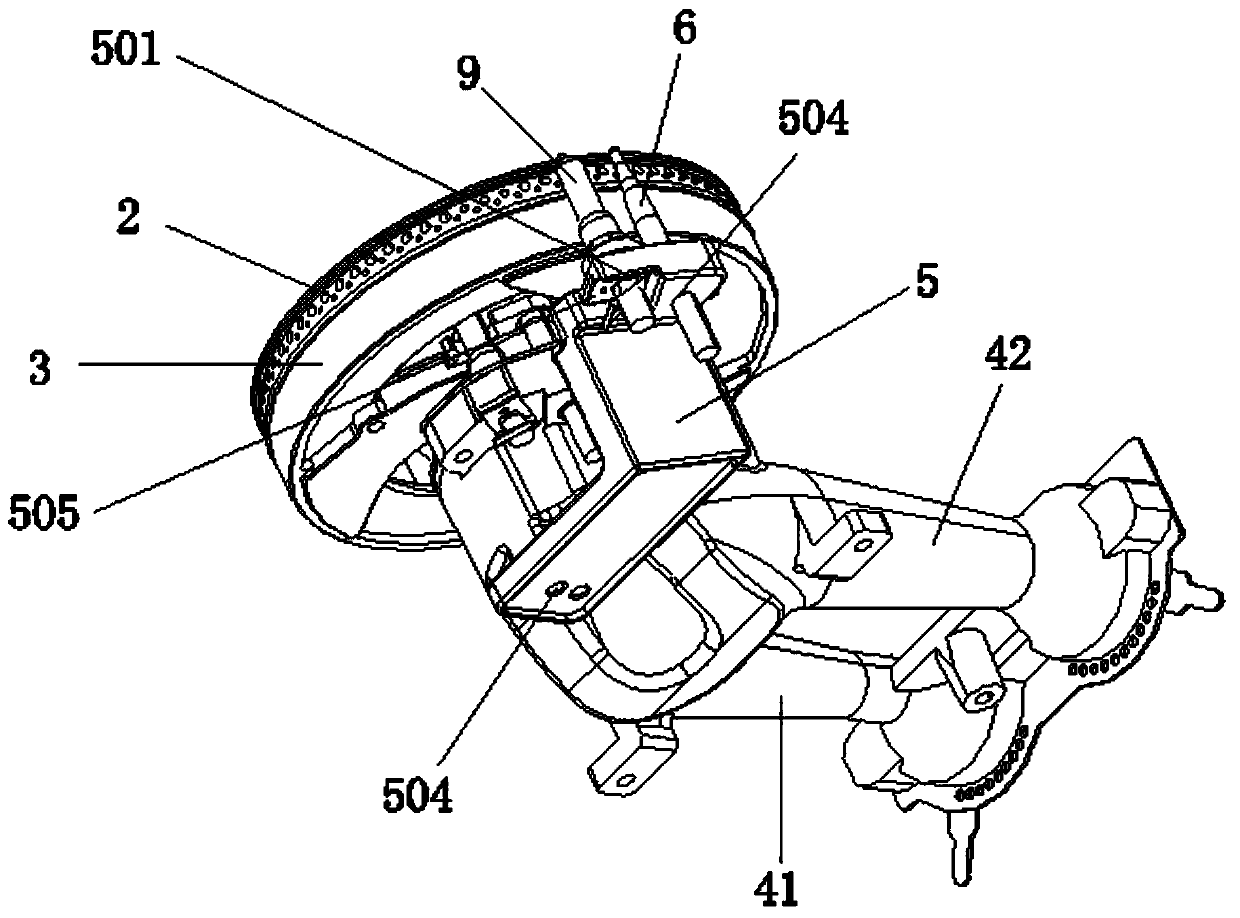

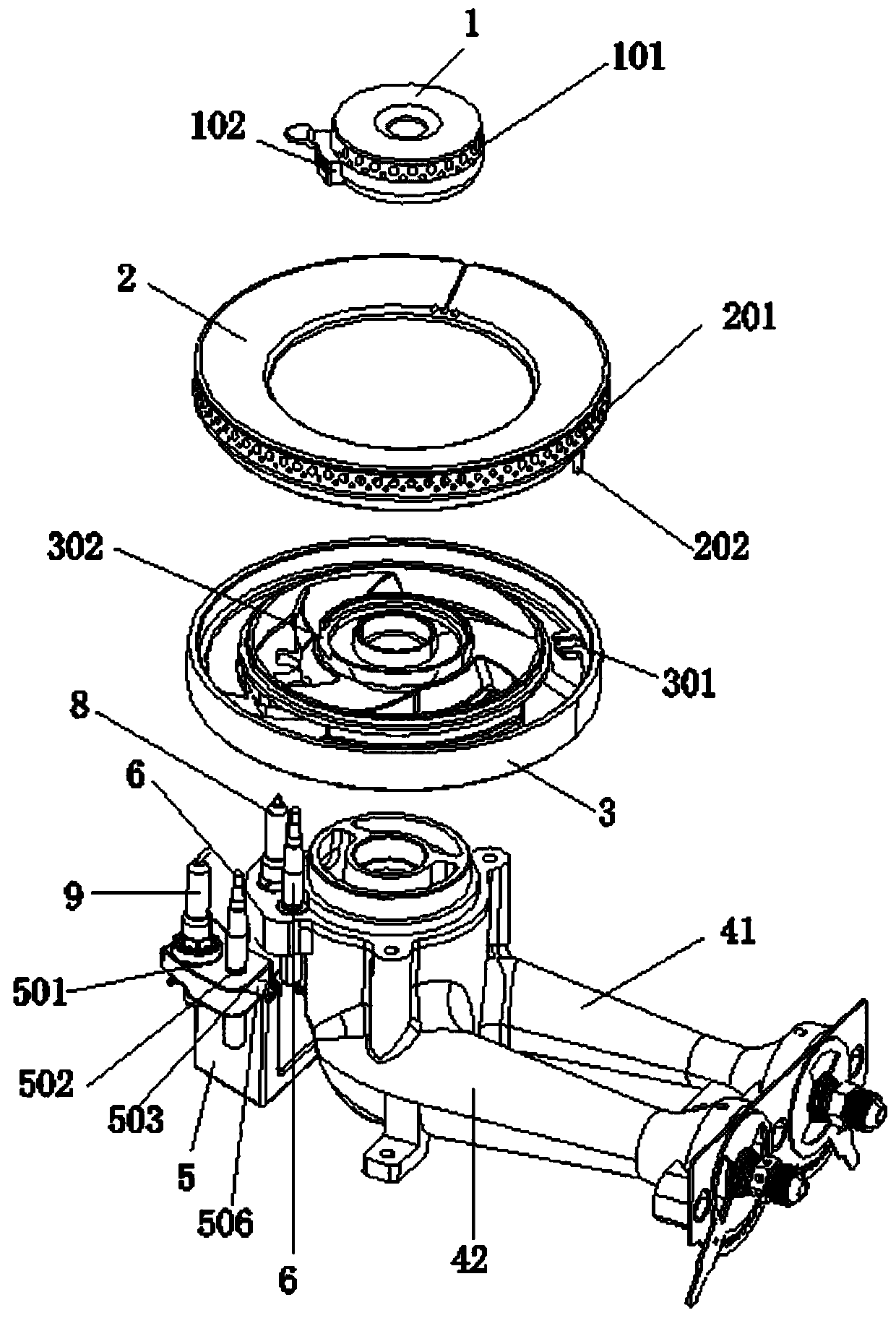

[0051] Such as Figure 1-4 As shown, this embodiment is a further limitation of the above embodiments. This embodiment discloses a gas stove, including a burner 4 with an inner ring gas channel 41 and an outer ring gas channel 42 . There is a fire cover seat 3, and the fire cover seat 3 is respectively provided with an inner ring fire cover 1 above the inner ring gas channel 41 and an outer ring fire cover 2 above the outer ring gas channel 42 from the inside to the outside. An inner ring ignition device electrically connected to the main controller 10 is provided between the cover 1 and the outer ring fire cover 2, and an outer ring ignition device electrically connected to the main controller 10 and arranged outside the outer ring fire cover 2 , the main controller 10 controls the operation of the inner ring ignition device and the outer ring ignition device.

[0052] Further, the inner ring fire cover 1 is designed as a circular structure, and uniform inner ring fire holes...

Embodiment 2

[0066] Such as Figure 1-3 and Figure 5 As shown, this embodiment is a further limitation of the above embodiments. The gas cooker further includes a first control mechanism, and the first control mechanism includes an outer ring gas pipeline 13 and an outer ring gas pipeline 13 On the first switch element 14 electrically connected to the main controller 10, one end of the outer ring gas pipeline 13 communicates with the main gas pipeline 11, and the other end communicates with the outer ring gas channel 42, so that the main The controller 10 controls the operation of the outer ring ignition device.

[0067] This embodiment also discloses a control method using the gas cooker as described above, including receiving user instructions, and the main controller 10 controls the inner ring ignition device and the outer ring ignition device to work according to the user instructions, and can also be used separately Control the operation of the outer ring ignition device.

[0068]...

Embodiment 3

[0076] Such as Figure 1-3 and Figure 6 As shown, the difference between this embodiment and the above embodiments is that: the gas cooker of this embodiment also includes a second control mechanism, and the second control mechanism includes an inner ring sub-pipeline 15 and an outer ring sub-pipeline 16, and the inner ring sub-pipeline 16 A second switch element 17 is arranged on the sub-pipeline 15, one end of the inner ring sub-pipeline 15 communicates with the main gas pipeline 11, and the other end communicates with the inner ring gas channel 41, and the outer ring sub-pipeline 16 is provided with a third switch Component 18, one end of the outer ring sub-pipeline 16 communicates with the main gas pipeline 11, and the other end communicates with the outer ring gas passage 42, so that the main controller 10 controls the inner ring ignition device and / or the outer ring ignition device Work.

[0077] This embodiment also discloses a control method using the gas stove as d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com