Slave cylinder for clutch release mechanism

A separation mechanism and clutch technology, applied in clutches, fluid-driven clutches, mechanically-driven clutches, etc., can solve the problems of quality and difficulty in forming the axial length of the outer sleeve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

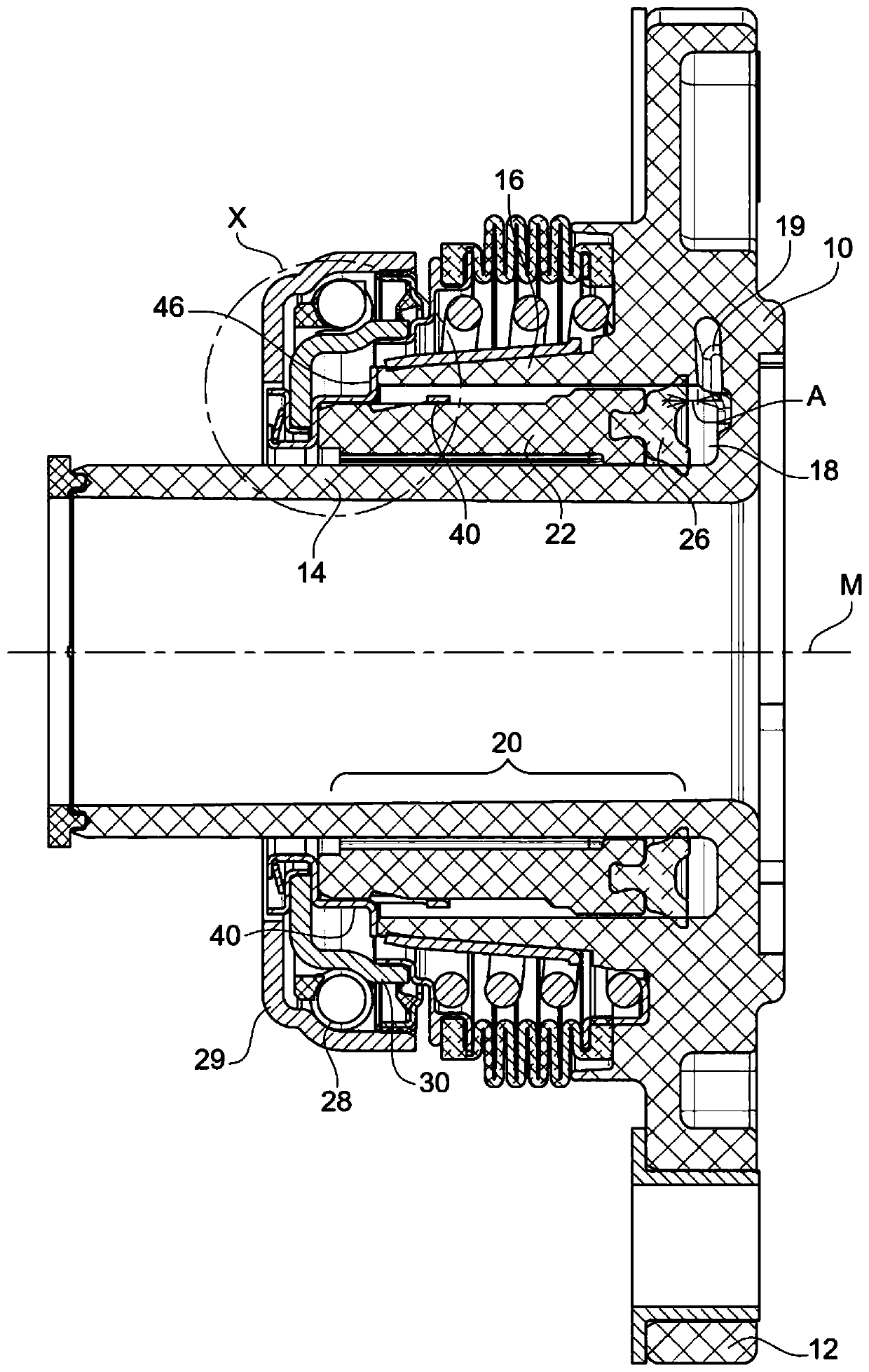

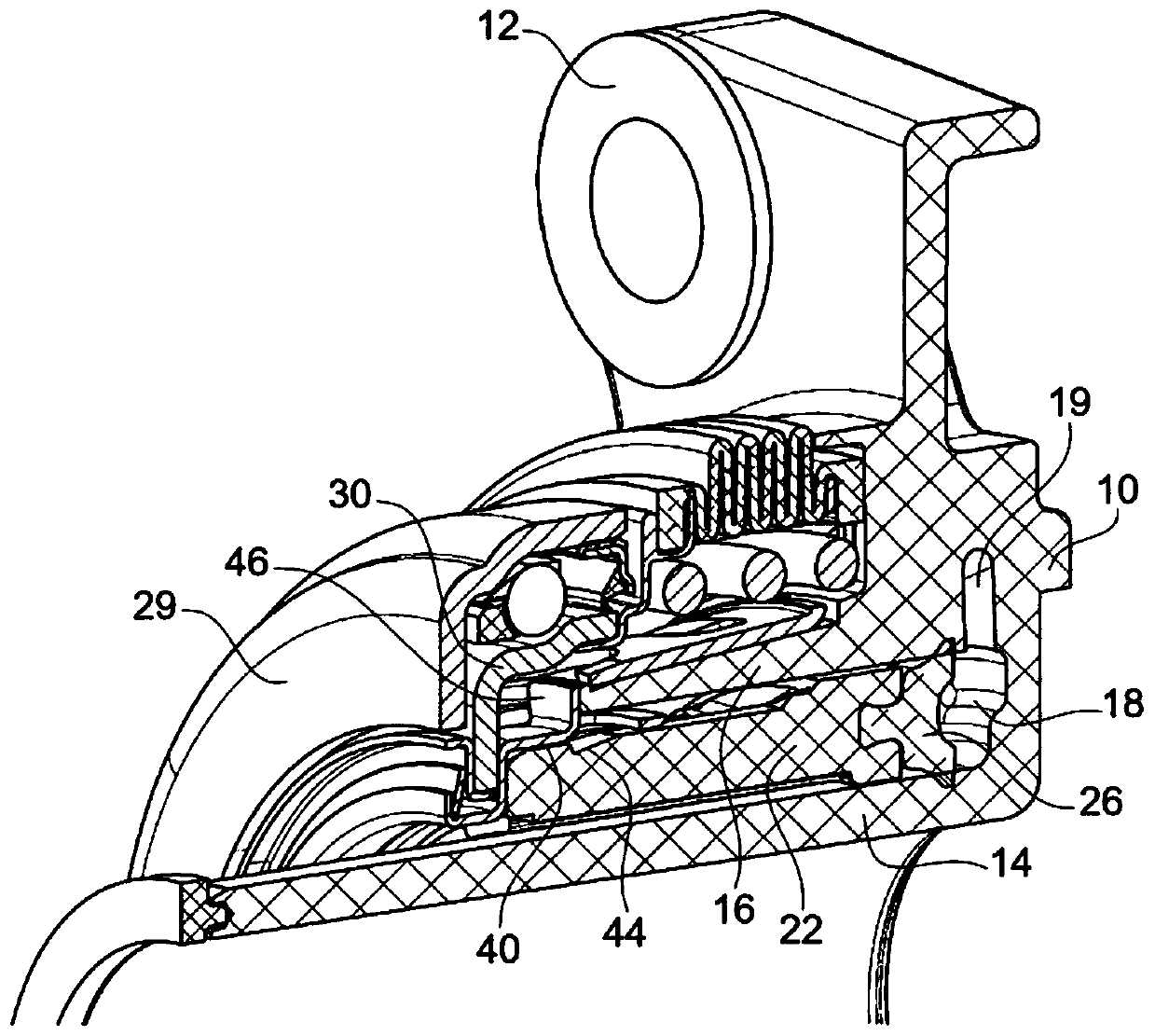

[0017] figure 1 Slave cylinder 1 is shown. It is a central separating device with a central axis M. Slave cylinder 1 is "CSC", which means concentric slave cylinder. The slave cylinder 1 is concentric with a transmission shaft such as an input shaft of a gearbox.

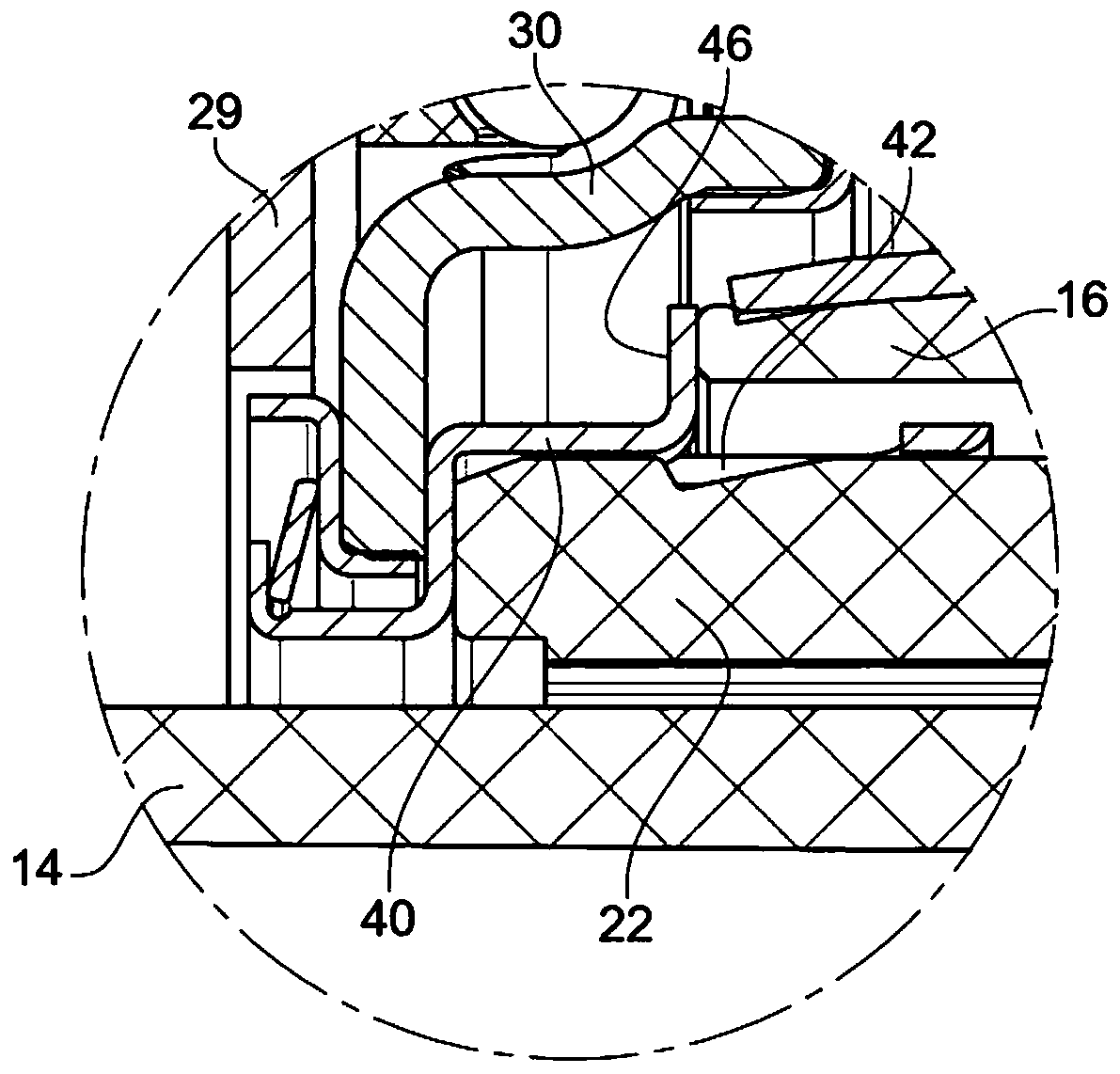

[0018] The slave cylinder 1 has a housing 10 with a mounting flange 12 , an inner sleeve 14 and an outer sleeve 16 . An annular space is formed between the inner sleeve 14 and the outer sleeve 16, which is formed by the material of the housing 10 at the "base" (in figure 1 to the right of ) is closed. Piston 20 (see figure 1 ) are movably arranged in the annular space.

[0019] The annular space thus forms an annular fluid chamber 18 , the inlet opening not shown here. If the fluid chamber 18 is filled with fluid and the pressure in the fluid chamber increases, the piston 20 acts on the left side (relative to figure 1 ).

[0020] The housing is usually an injection molded part made of plastic.

[0021] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com