A kind of mofs material and preparation method thereof

A technology of tetrazolium and rare earth salts, applied in the field of MOFs materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

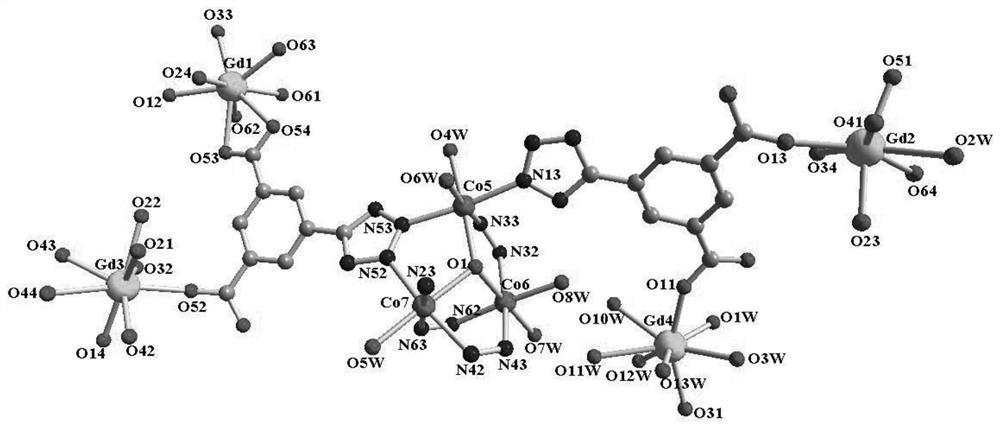

[0035] The present invention also provides the preparation method of the MOFs material according to the above technical solution, comprising the following steps: mixing 5-(1-H-tetrazolium)-isophthalic acid, cobalt source, rare earth salt, strong base and inorganic solvent Then, a hydrothermal reaction is performed to obtain the MOFs material. In the present invention, the hydrothermal reaction is carried out after mixing 5-(1-H-tetrazolium)-isophthalic acid, cobalt source, rare earth salt, strong base and inorganic solvent to coordinate organic ligands and metal ions The process of generating a skeleton structure.

[0036] In the present invention, the 5-(1-H-tetrazolium)-isophthalic acid can provide organic ligands and play a supporting role, and its chemical formula is H 3 TZI.

[0037] In the present invention, the cobalt source is preferably a divalent cobalt salt, more preferably cobalt nitrate or cobalt sulfate, more preferably Co(NO 3 ) 2 ·6H 2 O. In the present i...

Embodiment 1

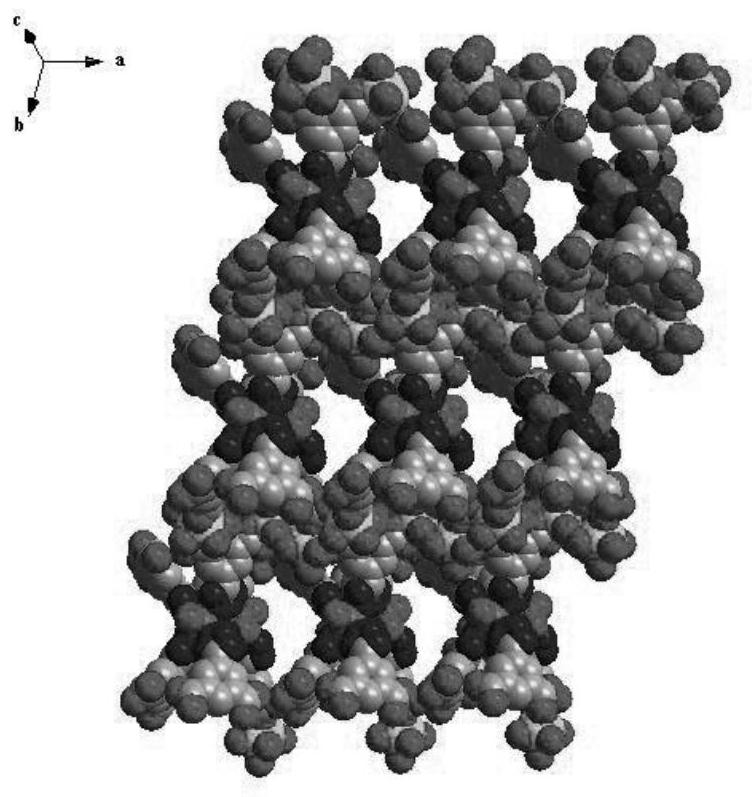

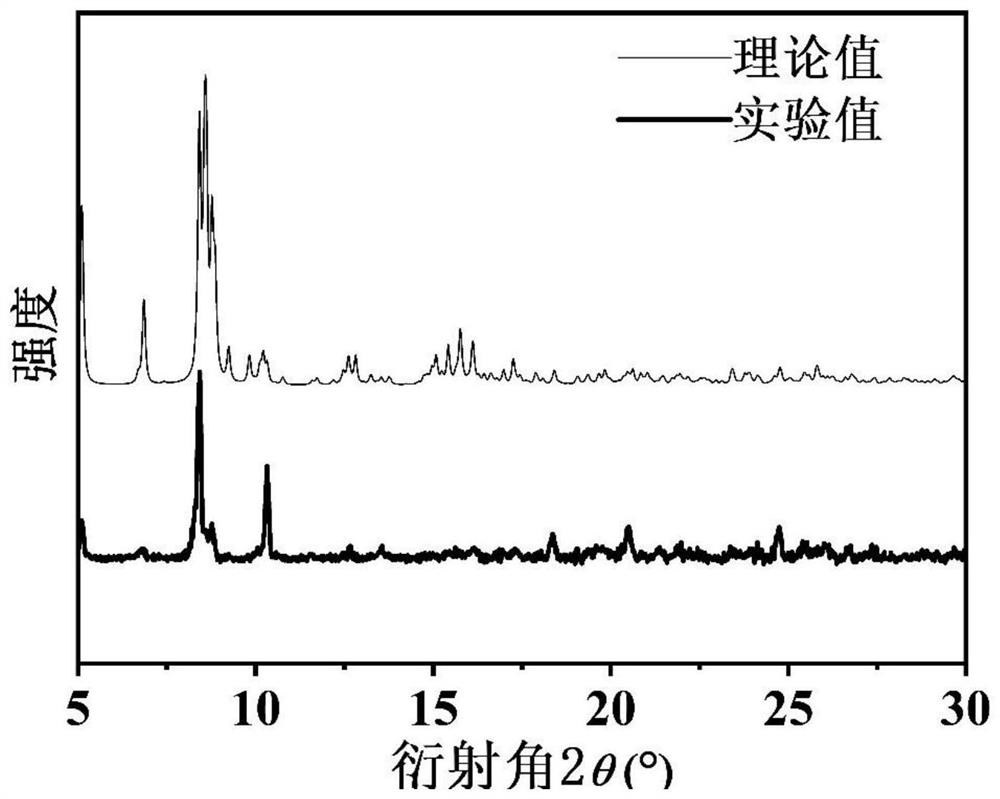

[0052] The Co(NO 3 ) 2 ·6H 2 O(0.1mmol), Gd(NO 3 ) 3 ·6H 2 O (0.1 mmol), 5-(1-H-tetrazolium)-isophthalic acid (0.18 mmol), sodium hydroxide (0.1 mmol) and water (7 mL) were mixed well (ie 5-(1-H- tetrazolium)-isophthalic acid, cobalt ions in cobalt sources, rare earth ions in rare earth salts, and OH in strong bases - The ratio of the amount of the substances is 9:5:5:5), conduct a hydrothermal reaction (the temperature of the hydrothermal reaction is 150°C, and the time is 72h), and finally cool to 30°C at a cooling rate of 2.5°C / hour, filter and washing to obtain light yellow bulk crystals, which are MOFs materials, the chemical formula is Co 3 Gd 4 (TZI) 6 ·9H 2 O, yield 78%.

Embodiment 2

[0054] The Co(NO 3 ) 2 ·6H 2 O(0.1mmol), Sm(NO 3 ) 3 ·6H 2 O (0.1 mmol), 5-(1-H-tetrazolium)-isophthalic acid (0.18 mmol), sodium hydroxide (0.1 mmol) and water (7 mL) were mixed well (ie 5-(1-H- tetrazolium)-isophthalic acid, cobalt ions in cobalt sources, rare earth ions in rare earth salts, and OH in strong bases - The ratio of the amount of the substances is 9:5:5:5), conduct a hydrothermal reaction (the temperature of the hydrothermal reaction is 150°C, and the time is 72h), and finally cool to 30°C at a cooling rate of 2.5°C / hour, filter and washing to obtain light yellow bulk crystals, which are MOFs materials, the chemical formula is Co 3 Sm 4 (TZI) 6 ·9H 2 O, yield 77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com