A light soil subgrade structure, subgrade system and design method

A design method and system design technology, applied in the field of geotechnical engineering, can solve the problems of high investment of pile-slab structure engineering, high bearing requirements of pile structure, damage to ecological environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

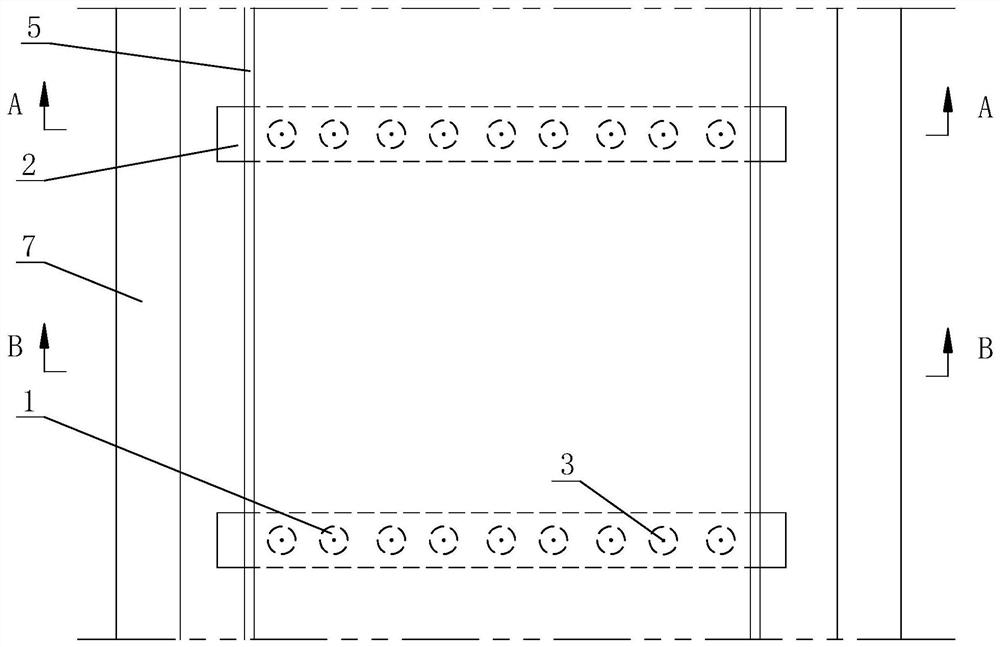

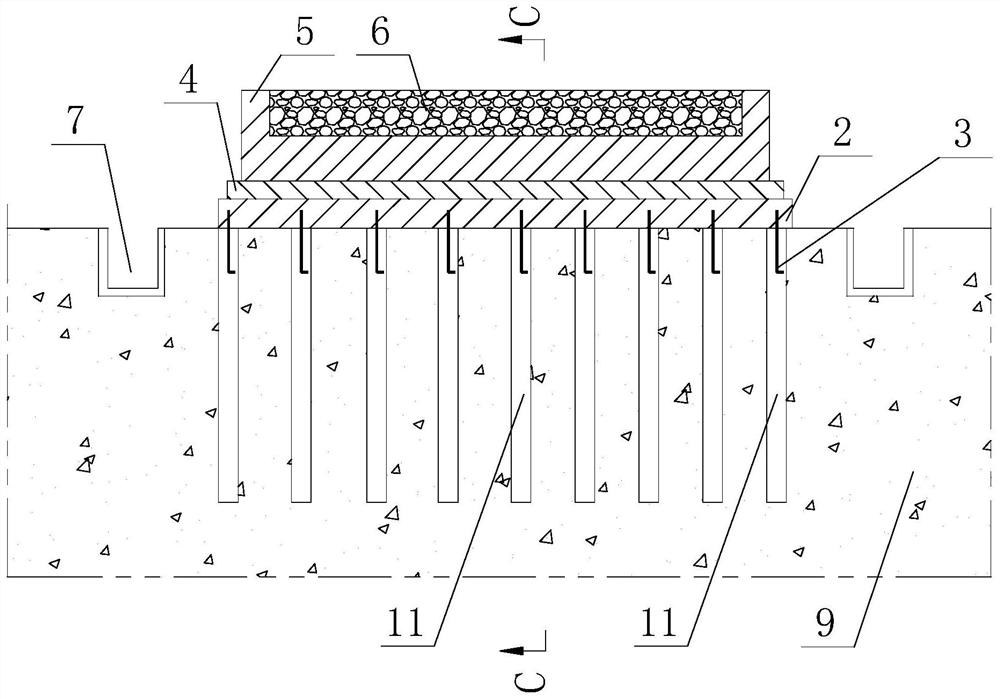

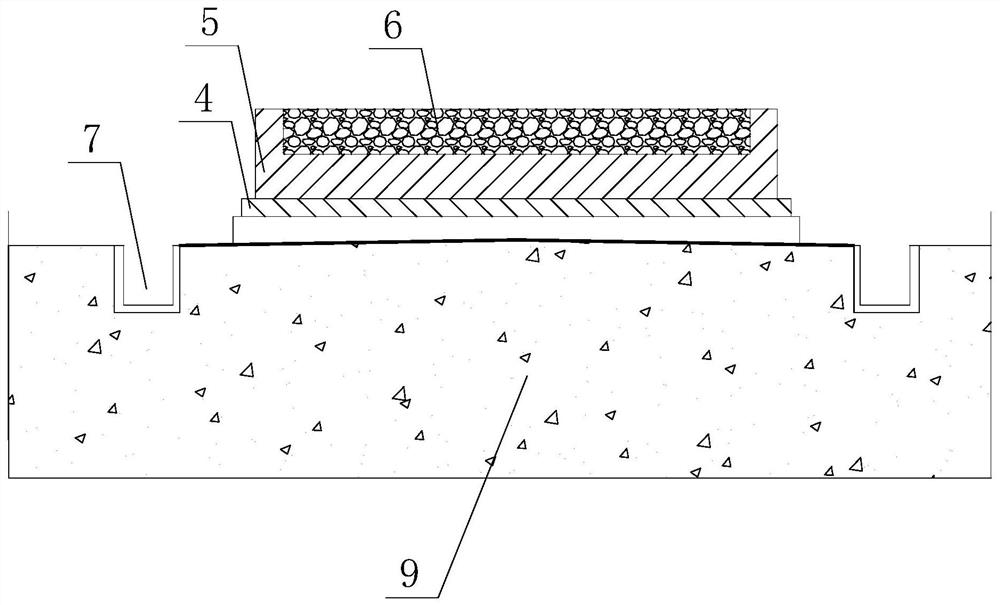

[0088] like Figure 1-4 As shown, a light soil subgrade structure includes a reinforcement pile assembly 1, which is connected to the bottom of the support beam 2. The reinforcement pile assembly 1 includes several reinforcement piles 11, and all the reinforcement piles 11 are connected to the bottom of the support beam 2. 2 Arranged at intervals along the length direction, reinforcement piles 11 are arranged in rows at intervals along the longitudinal direction of the line; support beams 2 are arranged on the pile tops of reinforcement piles 11; The plate 4 is arranged above the support beam 2 along the longitudinal section of the line; the U-shaped tank body 5 is arranged on the top of the support plate 4; the soil filler layer 6 is filled in the U-shaped tank body 5; the drainage ditch 7 is arranged on the U-shaped tank body Type groove body 5 both sides.

[0089] In the above scenario:

[0090] The length of the reinforcement piles 11 is not less than 1.2 times the atmos...

Embodiment 2

[0097] like Figure 1-4 As shown, a roadbed system described in this embodiment includes a foundation 9, the reinforcement pile 11 is arranged in the foundation 9, the support beam 2 is arranged on the foundation 9, adjacent to the support beam There is a gap between the support plate 4 between the two and the foundation 9 .

[0098] In the subgrade system described in this application, the support beam 2 is arranged on the foundation 9, which can be used to transfer the load of the U-shaped groove body 5 and the self-weight of the support plate 4 to the foundation 9 and the reinforcement pile 11, and to transfer the The uplift force at the bottom of the support beam 2 is transmitted to the reinforcement pile 11, and there is a gap between the U-shaped groove body 5 between the adjacent support beams 2 and the foundation 9, thereby avoiding the direct uplift force of the foundation 9 Acts on the bottom of the U-shaped groove.

[0099] On the basis of the above, in a further ...

Embodiment 3

[0103] like Figure 1-7 As shown, a design method for the subgrade system includes the following steps:

[0104] ① Determine the structural weight Wz of the support beam 2 by the following formula:

[0105] W z =BLHγ c

[0106] where W z is the structural weight of the support beam 2, unit kN; B is the width of the support beam 2, unit m; L is the length of the support beam 2, unit m; H is the height of the support beam 2, unit m; γc is Reinforced concrete weight, unit kN / m 3 ;

[0107] ② Determine the structural weight Wu of the support plate 4 by the following formula:

[0108] W u =bhSγ c

[0109] where W u is the structural weight of the support plate 4, unit kN; b is the width of the support plate 4, unit m; h is the thickness of the support plate 4, unit m; S is the distance between adjacent support beams 2, unit m ;

[0110] ③Determine the weight Wt of the structure of the U-shaped tank body 5, the soil filling layer 6 and the upper track structure by the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com