A rice milling device

A technology of outer cylinder and inner cylinder, which is applied in the field of rice processing, can solve problems such as friction obstruction and affecting rice husking, and achieve the effects of reducing broken rice, improving falling efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

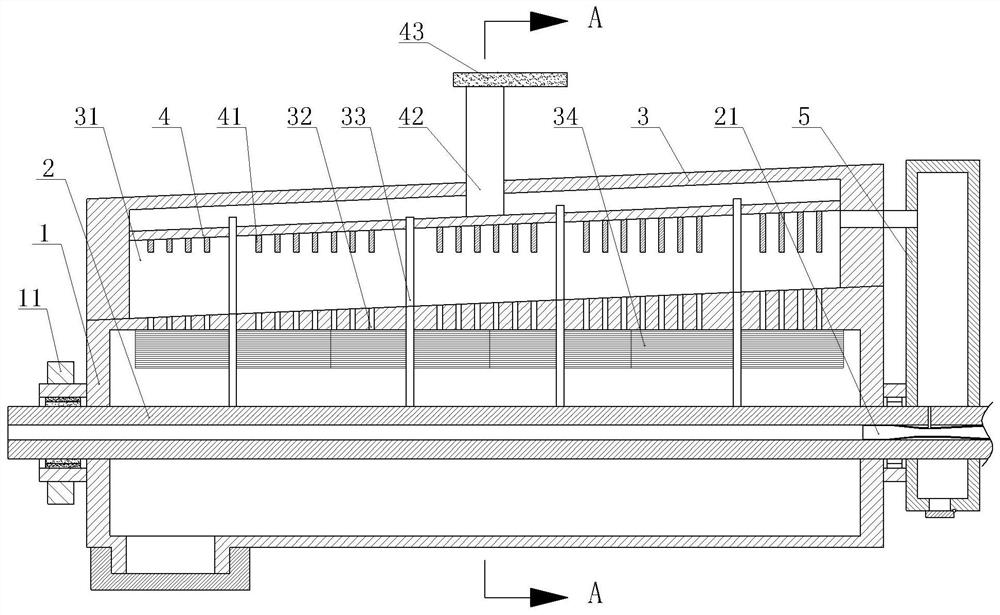

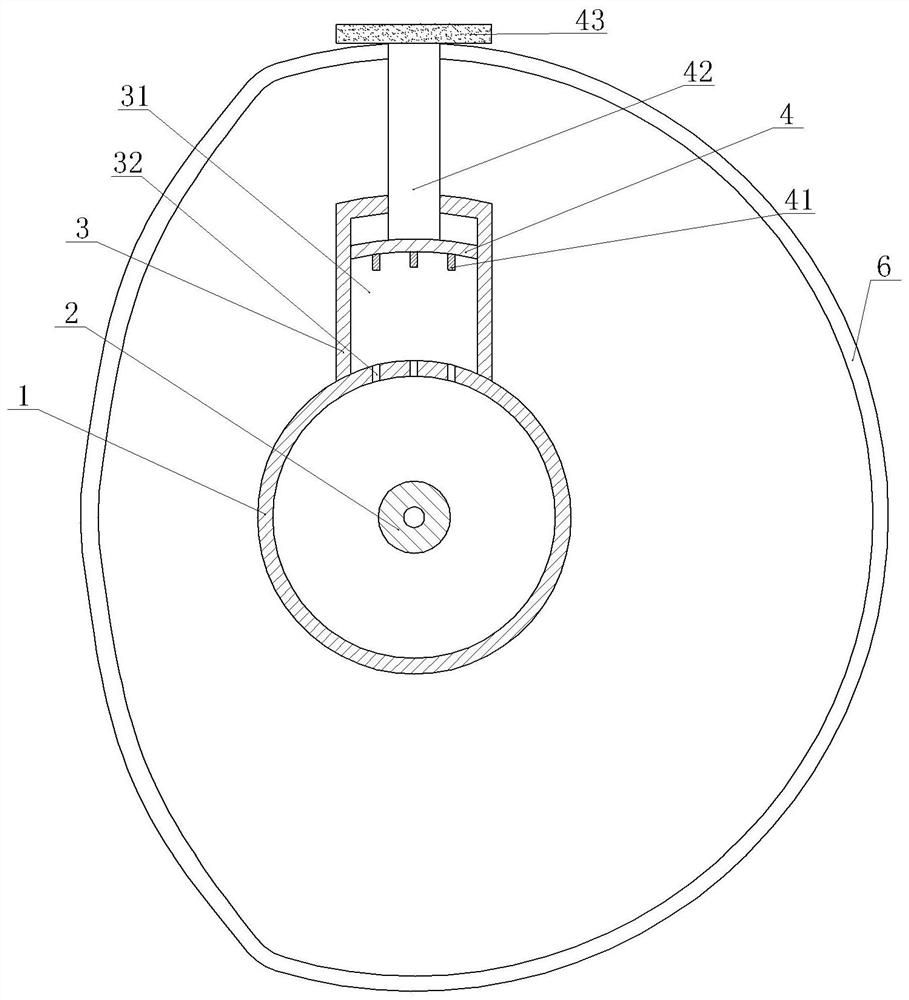

[0034] A rice milling device, such as figure 1 As shown, it includes a frame, a driving part, an outer cylinder 1 and an inner cylinder 2 located in the outer cylinder 1. In this embodiment, the outer cylinder 1 and the inner cylinder 2 are coaxial, and the two ends of the outer cylinder 1 are welded with installation shafts. The end of the installation shaft away from the outer tube 1 runs through the frame and is matched with the frame in clearance. The mounting shaft on the left side is connected with the driven gear 11 by a flat key, and the driving part is fixed on the frame by bolts. Gear 11 meshes with the driving gear. The bottom of the outer cylinder 1 is provided with a feeding port and a feeding port cover. The feeding port cover is threadedly matched with the feeding port to close the feeding port; A one-way intake valve for air intake in barrel 1.

[0035] The top of the outer cylinder 1 is welded with a separation barrel 3 with the opening facing downward. Th...

Embodiment 2

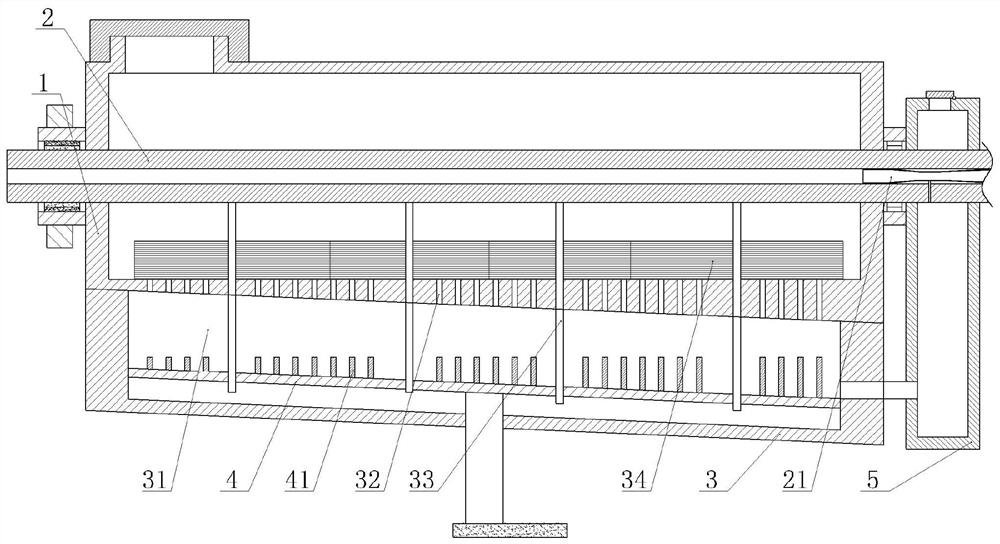

[0045] On the basis of Example 1, such as Figure 4 As shown, the part of the guide rod in this embodiment located between the outer cylinder 1 and the inner cylinder 2 is wave-shaped, and the rotating rod 33 is in clearance fit with the piston 4 to ensure that the rotating rod 33 can rotate relative to the piston 4 . Inner tube 2 outer wall is provided with annular guide groove 23, and guide groove 23 internal gaps are matched with spherical guide block, and the diameter of guide block is greater than the diameter of rotating rod 33, and the lower end of rotating rod 33 stretches in the guide groove 23 and connects with guide block. welding. The lower end of the guide rod is fixed with a first bevel gear through a flat key, and a second bevel gear 22 meshing with the first bevel gear is welded on the side wall of the guide groove 23 .

[0046] When the outer cylinder 1 in this solution rotates, the rotating rod 33 rotates with the outer cylinder 1, and the first bevel gear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com