Support wing aircraft

A technology for supporting wings and aircraft, applied in the direction of wings, aircraft parts, fuselage, etc., can solve the problem of not setting the wing interconnection area, and achieve the effect of reducing cost and weight, reducing relative quantity, and simplifying wing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

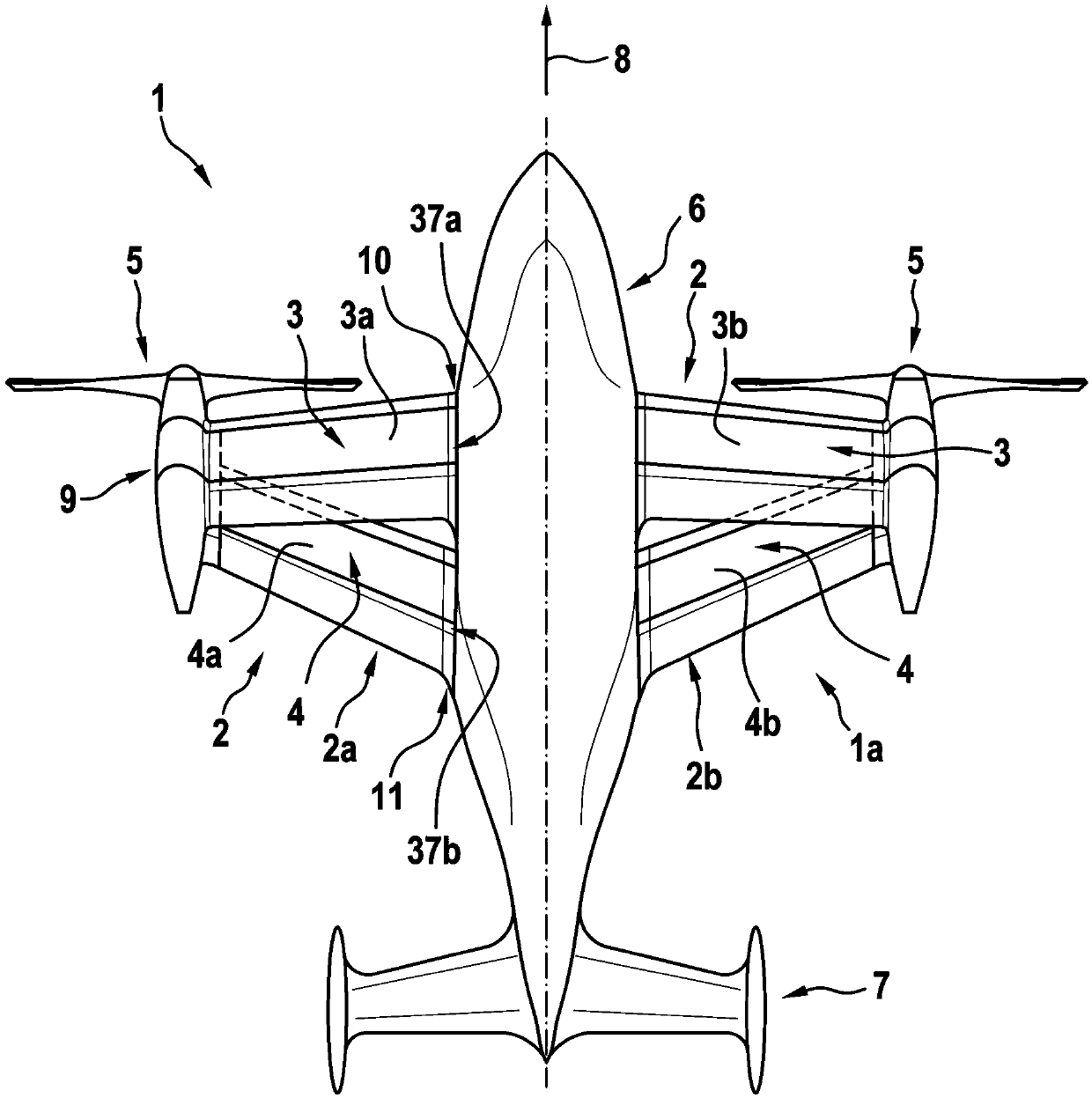

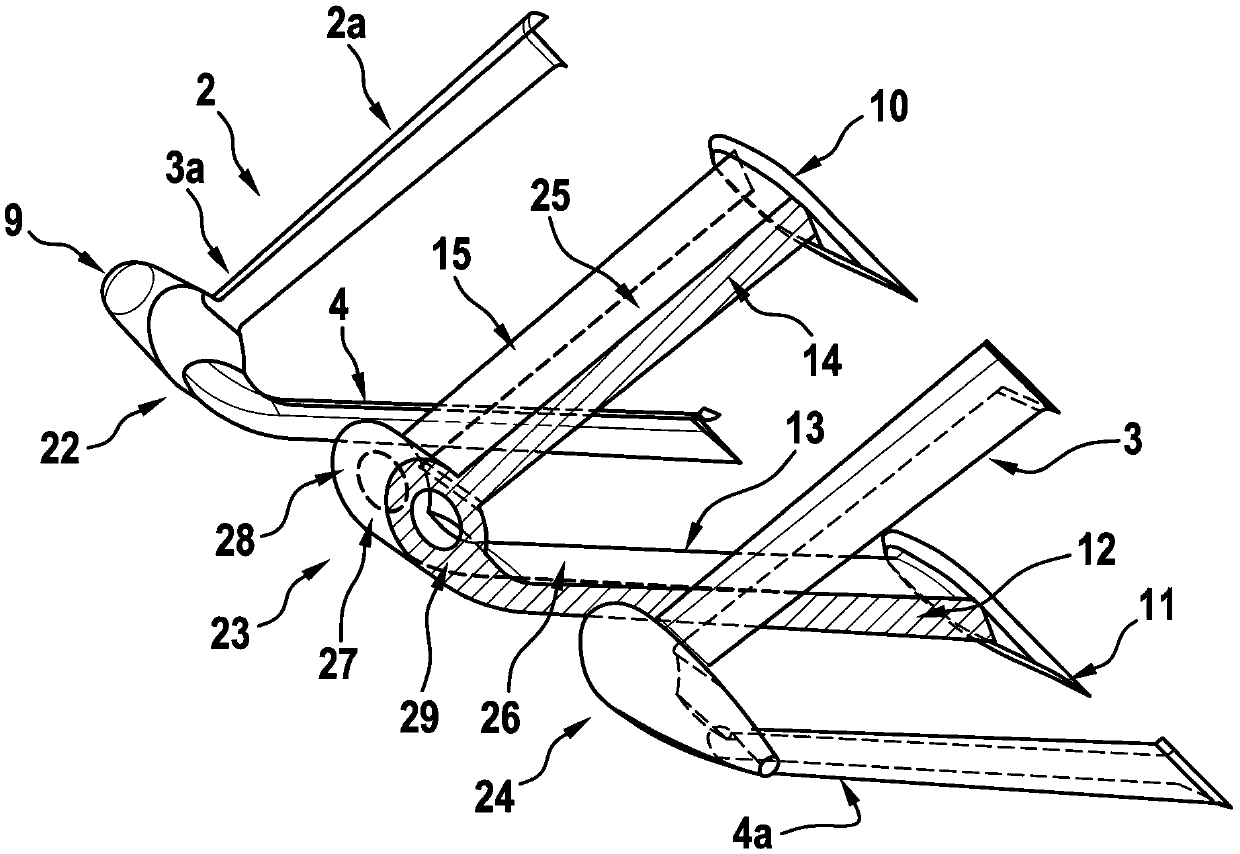

[0057] figure 1A strut-wing aircraft 1 is shown having a fixed-wing configuration 1 a and a fuselage 6 . The fixed wing configuration 1a preferably comprises two or more support wings 2 provided with an upper wing 3 and a lower wing 4 each. Schematically, the fixed-wing configuration 1a includes a first supporting wing 2a and a second supporting wing 2b, which are arranged on the side of the fuselage 6 and facing each other. The first support wing 2 a is exemplarily mounted to the starboard side of the support wing aircraft 1 , and the second support wing 2 b is exemplarily mounted to the port side of the support wing aircraft 1 .

[0058] According to one aspect, the supporting wing 1 is provided with suitable propulsion means 5 and empennage 7 . Schematically, the propulsion means 5 are represented as pull-in propellers, but they may also be represented as push-type propellers. Likewise, the propulsion means 5 may be fixedly mounted or alternatively embodied as a tilted r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com