Method for reducing coal water slurry gasification ash water suspended solids

A technology for suspended solids and coal-water slurry, applied in the field of coal chemical industry, can solve the problems of affecting the smooth operation of sewage treatment, large use of flocculants, equipment scaling, etc., to reduce equipment cleaning times, reduce suspended solids content, and optimize water quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

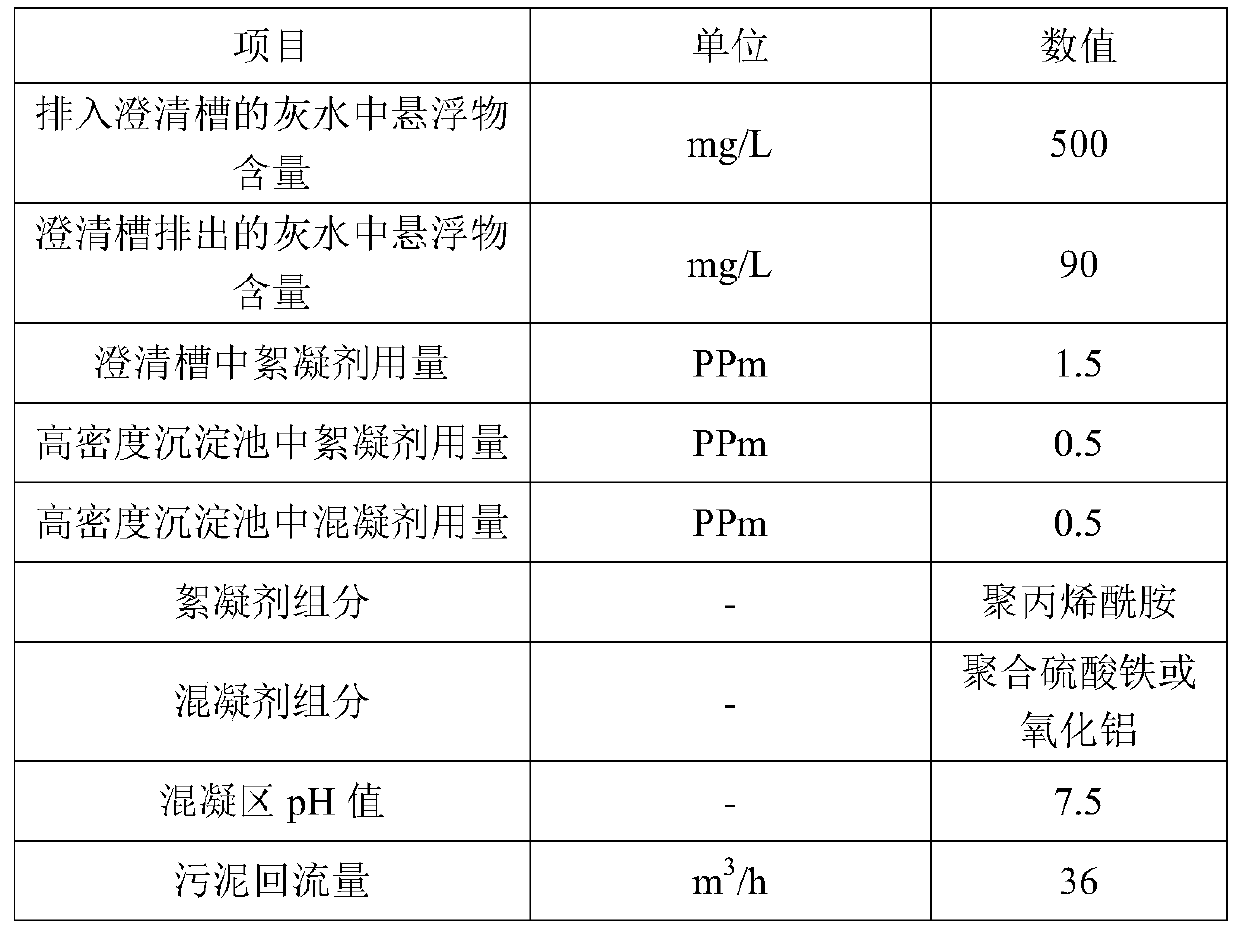

[0039] figure 1 The treatment process for reducing the content of suspended solids in coal-water slurry gasification ash water provided by this embodiment, figure 2 For the structure of the high-density sedimentation tank used in this embodiment, in this embodiment, the gasified ash water produced by the coal-water slurry gasification device is discharged into the clarification tank, and the concentration of the gray water in the ash water is reduced by adding flocculants to the clarification tank. The suspended matter is subjected to a flocculation treatment once, and the suspended matter is flocculated and then settled. After the settlement, the gray water in the clear liquid area in the clarification tank is discharged into the high-density settling tank; the gray water discharged into the high-density settling tank passes through the high-density settling tank in sequence Coagulation treatment in the coagulation zone in the density settling tank, secondary flocculation tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com