A multi-axis positioning power equipment inspection and maintenance platform for electric power engineering and its implementation method

A technology of power equipment and power engineering, applied in the field of multi-axis positioning power equipment maintenance pan/tilt in power engineering, can solve the problems of small inspection range and limited application range, and achieve reduced work intensity, high safety, and wide inspection range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

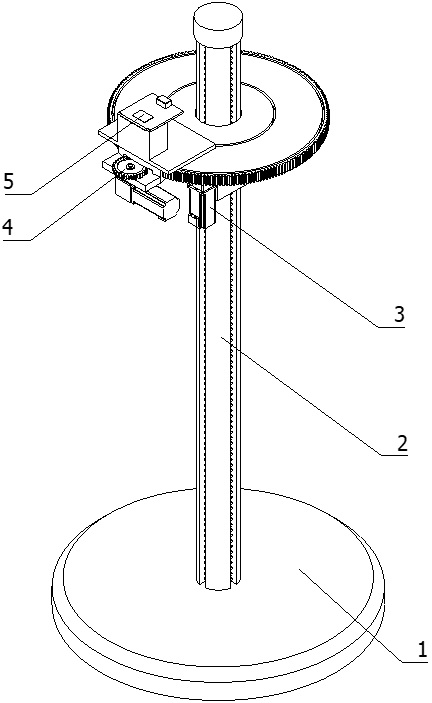

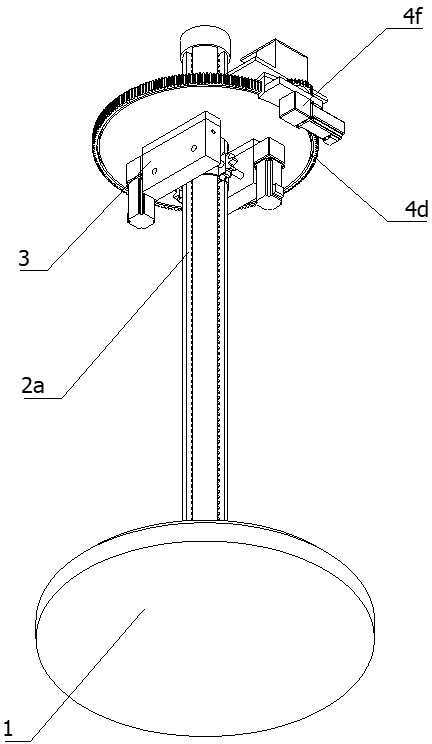

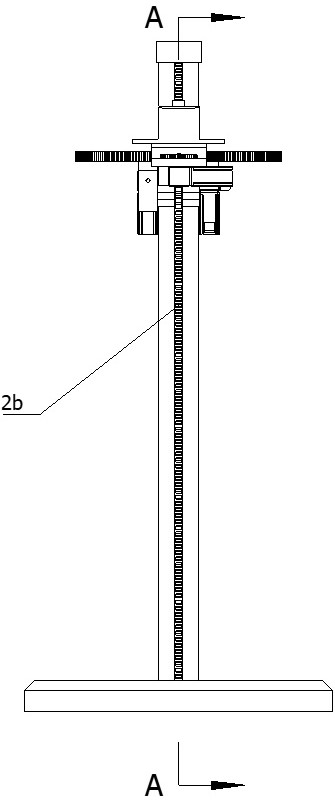

Image

Examples

Embodiment approach

[0065] A method for implementing a multi-axis positioning power equipment inspection and maintenance platform in electric power engineering, including the following steps:

[0066] Step 1. The staff sends a signal to the self-climbing mechanism 3 through the controller, and after receiving the signal, the self-climbing mechanism 3 drives the self-climbing mechanism 3 to climb along the axis of the climbing pole 2;

[0067] Step 2. During the climbing process, the linear displacement sensor feeds back the sensed moving distance to the controller, and the controller precisely regulates the lifting speed and distance of the self-climbing mechanism 3 according to the received displacement signal;

[0068] Step 3. During the lifting process from the climbing mechanism 3, the controller also sends a signal to the slewing mechanism 4. After receiving the signal, the working end of the slewing mechanism 4 rotates around the axis of the climbing rod 2, and the working end of the slewing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com