A metal parts sorting and sorting device

A technology for sorting devices and metal parts, which is applied to conveyor objects, transportation and packaging, vibrating conveyors, etc. Out of control attitude, high sorting efficiency, good promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

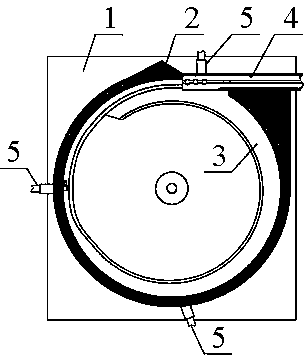

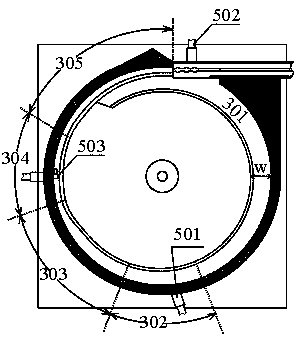

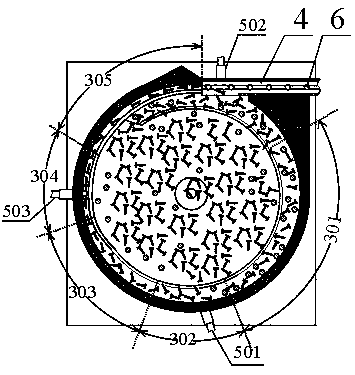

[0044] Such as Figure 1 to Figure 8 As shown, the metal parts sorting and sorting device includes an electromagnetic torsion vibrator 1 for generating torsional vibration, a vibrating plate 2 installed on the upper part of the electromagnetic torsion vibrator 1, and a feeding pan groove 3 arranged inside the vibrating plate 2, wherein: Both the electromagnetic torsion vibrator 1 and the vibrating plate 2 adopt existing devices. The electromagnetic torsion vibrator 1 includes a pulse electromagnet and a spring sheet. The pulse electromagnet is installed at the bottom of the vibrating plate 2, and the vibrating plate 2 is installed on the On the base, the vibrating plate 2 vibrates vertically up and down through the power on and off of the pulse electromagnet. Due to the setting of the inclined spring piece, the vibrating plate 2 will vibrate in one direction, and the materials in the vibrating plate 2 and the feeding plate groove 3 Under the above-mentioned active force, it wi...

Embodiment 2

[0058] On the basis of Embodiment 1, in order to facilitate transportation or packaging, the end of the screening chute 4 extends downward to form an arc-shaped outlet 407. The arc-shaped outlet 407 is used to guide the parts 6 to fall into the conveyor belt 7 or packaging orderly in a horizontal state. Bag 8, specifically as Figure 9 and Figure 10 shown.

Embodiment 3

[0060] On the basis of Embodiment 1, in order to facilitate transportation or packaging, a sorting magnetic field device 9 is arranged at the exit of the screening chute 4, and the sorting magnetic field device 9 is used to form a sorting magnetic field to guide the falling of parts 6 in a specific posture, such as Figure 11 shown.

[0061] It should be noted that, after the part 6 slides out from the screening chute, it will enter the specific magnetic field formed by the sorting magnetic field device 9. At this time, the part 6 is subjected to two forces of gravity and magnetic force. , can realize the part 6 falling in a specific posture, for example, realize the part 6 falling in a horizontal posture.

[0062] It should be further explained that some parts have certain magnetic properties after forging and heat treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com